In-Depth Analysis: What Secrets Are Hidden in the "Dual-Pore Structure" Polyimide Insulation Materials?

Abstract:

Polyimide (PI)-based materials are highly favored in the field of thermal insulation due to their excellent intrinsic physicochemical properties, and are widely used in industries such as aerospace, construction engineering, and microelectronics. This paper systematically reviews the latest research progress on porous polyimide thermal insulation materials and proposes a novel classification standard based on pore structure. Firstly, specific models are analyzed to reveal pore structure characteristics and internal heat transfer mechanisms. Secondly, the main preparation and forming methods of various structures are summarized, and modification schemes for optimizing thermal insulation performance are listed and analyzed. Finally, the advantages and disadvantages of two typical structural features are comprehensively discussed, with further exploration of the optimal application paths for different characteristics, as well as potential directions for performance design and application expansion. The conclusions of this study are expected to provide a solid theoretical foundation and important technical reference for the design and development of high-performance polyimide-based thermal insulation materials.

1. Introduction

With the continuous advancement of society and industrial processes, global energy demand is steadily rising. Energy crises and environmental issues are becoming increasingly severe, prompting countries to actively implement energy-saving and emission-reduction policies. During the development and utilization of new energy, a significant amount of energy dissipates as heat into the environment within energy conversion systems. This not only leads to energy waste but also exacerbates greenhouse gas emissions. Against this backdrop, thermal insulation materials, due to their significant energy-saving and emission-reduction potential, as well as their ability to enhance thermal comfort, have gained widespread attention. In the military aviation sector, aircraft operating in extreme thermal environments rely on high-performance thermal protection systems to ensure the safety and normal operation of internal equipment. In the construction industry, thermal insulation materials help improve the thermal resistance of building envelopes, reducing HVAC energy consumption. Additionally, in fields such as electronic devices, these materials can extend the lifespan of components and improve safety. Broadly speaking, thermal insulation materials refer to materials with low thermal conductivity and porous structures, effectively inhibiting heat flow transfer and possessing both insulation and thermal barrier functions. Their performance depends on the intrinsic properties of the materials and the characteristics of their microstructures. Currently, common thermal insulation materials include metals, inorganic ceramics, and organic polymers. Among them, polymer-based materials have become a focus of research and application due to their advantages such as light weight, high specific strength, good chemical stability, and customizability.

Among the many high polymer thermal insulation materials, polyurethane (PU), phenolic resin (PF), polystyrene (PS), epoxy resin (EP), and polyimide (PI) are widely used. PI, as a polymer material with an imide five-membered heterocycle in its main chain, exhibits excellent thermal stability and mechanical strength, and has been widely applied in aerospace, electronics, construction, and other fields. For example, PI films are used as multilayer insulation materials in the European Space Agency’s Gaia telescope and NASA’s James Webb Space Telescope, serving functions of thermal protection, radiation shielding, and structural protection. As early as the 1970s, the NASA Langley Research Center collaborated with Unitika America to develop PI foam insulation materials. With technological advancements, the forms of PI insulation materials have become increasingly diverse, including porous films, foams, and aerogels. The pore structures vary significantly due to differences in fabrication methods and molecular structures, which have a direct impact on the thermal transfer behavior of the materials.

Heat transfer in porous materials involves multiple mechanisms, including thermal radiation, convection, and conduction through both solid and gas phases. For PI materials with micro/nanoporous structures, thermal conduction is mainly governed by solid and gas phase heat transfer, in which porosity and pore morphology play crucial roles. Although the influence of pore structure on thermal insulation performance has been widely recognized, there is still a lack of systematic summary and comparative analysis of the thermal insulation mechanisms of PI materials with different pore structures.

Therefore, this paper classifies polyimide thermal insulation materials into two categories based on pore structure characteristics: "channel-like pore structures" and "bubble-like pore structures." Corresponding thermal insulation models are established for each category, systematically explaining their insulation mechanisms and reviewing related research progress. There are significant differences between these two structures in terms of pore scale, dominant insulation mechanisms, preparation methods, and applicable scenarios. This paper aims to provide a theoretical basis and technical reference for the design and development of high-performance PI thermal insulation materials.

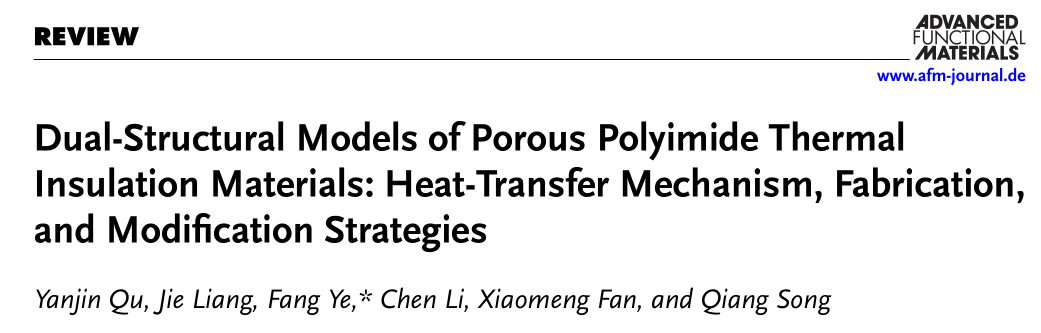

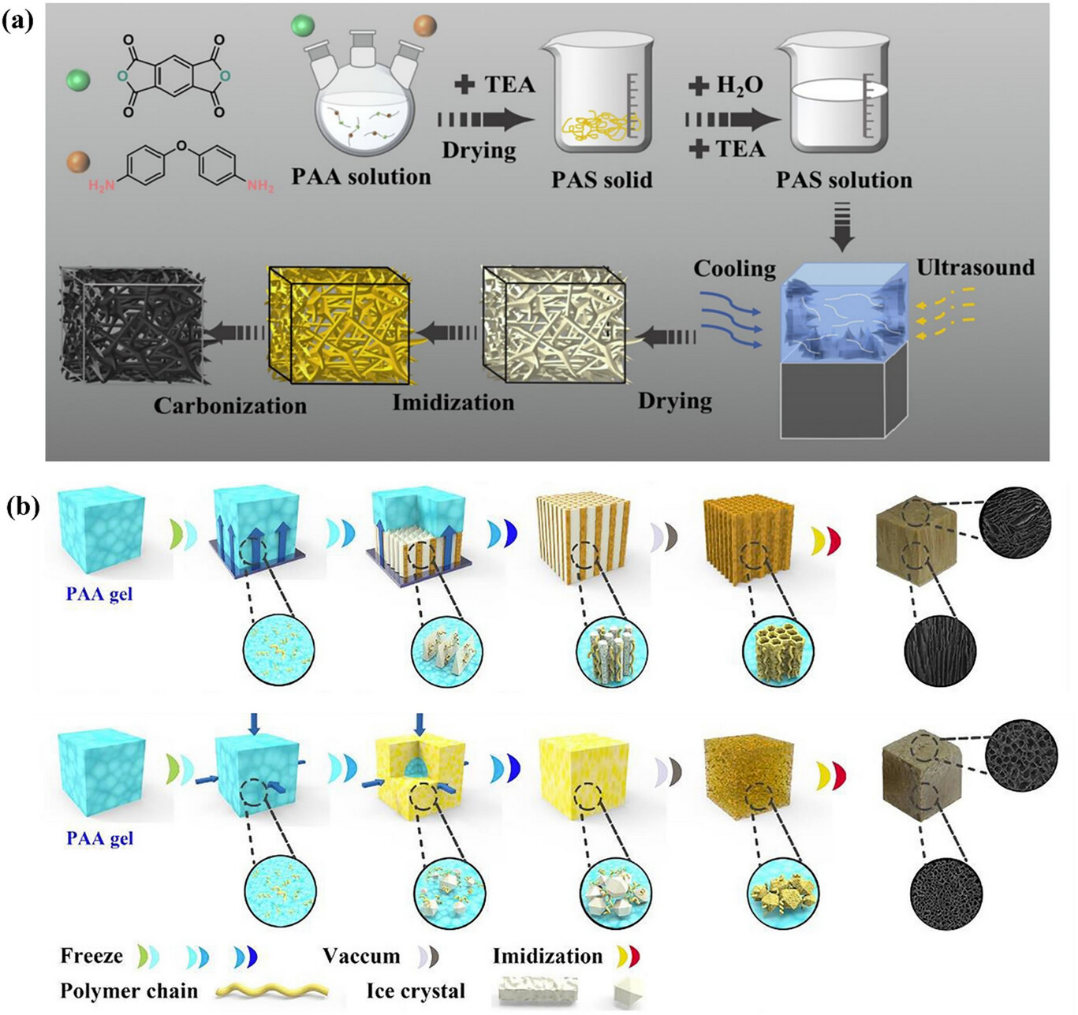

Figure 3 Overview of the freeze-drying preparation process. a) Schematic illustration of the entire process for preparing PI porous materials by combining freeze-drying and thermal imidization. b) Schematic diagrams of PI aerogels prepared by unidirectional freezing and random freezing methods. Note: Figures are from the original article, and the copyright belongs to the original authors.

2 PI with channel-like pore structure

Channel-like pore structures refer to interconnected pore networks formed within the PI matrix, characterized by high porosity and obvious disorder, often exhibiting irregular morphologies such as honeycomb or web-like patterns. In these materials, the PI framework serves as the support, while the air pores play the primary role in thermal insulation. Heat transfer includes phonon transport within the gas channels and phonon conduction across interfaces, and the gaseous phase thermal conductivity behavior can be described using the Kaganer model.

Increasing porosity helps to raise the proportion of the gas phase and significantly reduce the overall thermal conductivity of the material. The coupling effect caused by gas-solid molecular collisions can further suppress gas-phase thermal conduction. Reducing pore size limits the mean free path of phonons in air, thereby enhancing thermal insulation performance. According to the Knudsen effect, when the pore size is smaller than the mean free path of air molecules (approximately 70 nm), the material’s thermal conductivity can even be lower than that of static air.

To achieve this ideal structure, precise pore-forming technology is required. Channel-structured PI materials typically exhibit characteristics such as ultra-high porosity, ultra-low density, and low solid content, making ultra-light aerogels a current major research focus.

Conventional preparation processes often combine polymer synthesis with pore-forming steps, such as introducing a pore-forming step during the polymerization of PI. Typically, a precursor salt is first formed by the condensation of diamines and dianhydride monomers, which is then converted into polyimide through chemical or thermal imidization and completed with curing. The pore structure can be constructed at different stages of the imidization process.

Early methods mostly used freeze-drying. Before imidization, ice crystal–polymer bicontinuous frameworks were formed through directional or random freezing. The ice crystals were then removed by vacuum sublimation, and finally, thermal imidization yielded the porous materials. This method is low-cost, environmentally friendly, and widely applied. In addition to thermal imidization, aerogels can also be prepared by chemical imidization combined with supercritical drying. In this approach, acetic anhydride and pyridine are used to catalyze the acylation reaction, and solvents are removed under supercritical conditions. However, the process is time-consuming and requires sophisticated equipment.

Direct forming processes like electrospinning can transform a homogeneous PAA solution into a nanofiber assembly, which can be further processed through drying to form fiber membranes or aerogels with excellent thermal insulation potential. Other technologies such as PI fiber self-assembly and 3D printing are also under research, but face limitations in terms of printability, precision, and cost.

Nevertheless, there are still issues such as structural shrinkage and pore collapse in the preparation of such materials. During the drying process, solvent evaporation induces capillary forces, which can easily lead to the shrinkage of pore structures; the high-temperature treatment during the imidization phase may also cause secondary collapse. These factors can all affect the stability of the materials in practical applications. To improve structural stability and thermal insulation performance, researchers have approached the problem from multiple aspects, including molecular design, component regulation, and surface modification.

-

Molecular chain design: By introducing rigid groups or cross-linked structures, the dense packing of molecular chains is inhibited and the backbone strength is enhanced.

-

Component design: Add SiO₂ nanoparticles, glass fibers, and other fillers to improve pore uniformity, inhibit shrinkage, and reduce thermal conductivity.

-

Surface modification: Hydrophobic treatment (such as fluorocarbon resin coating, proton implantation, etc.) is used to improve the moisture resistance and stability of the material.

Despite the excellent thermal insulation properties and extremely low density of channel-structured PI, issues such as insufficient mechanical strength and moisture absorption due to its porous structure still limit its practical applications in various fields to some extent.

3 PI with a bubbly pore structure

The bubble-like pore structure is primarily composed of closed cells, with the pores being approximately spherical in shape and arranged in a relatively regular pattern. In such materials, heat transfer is predominantly governed by phonon transmission at the gas-solid interface and conduction through the polymeric framework. The closed-cell structure can effectively prevent gas convection and extend the heat flow path, thereby reducing thermal conductivity. Increasing the closed-cell ratio helps to enhance insulation performance, but reducing the pore size often increases the proportion of the solid phase, which may conversely lead to an increase in thermal conductivity. Therefore, precise control of the solid phase content is necessary. These materials are often prepared using foaming techniques, including physical foaming, chemical foaming, and phase separation methods. Basic methods such as powder foaming create pores through the evaporation of residual solvents; chemical foaming uses CO₂ generated in situ from isocyanate routes as a foaming agent. Supercritical fluid foaming technology, which does not require chemical additives and is environmentally friendly, is especially suitable for preparing microporous PI foams.

The phase separation method forms porous structures by regulating the phase domains in incompatible systems, but the process is complex and the pore size is usually large. In the foaming process, the type of foaming agent, the characteristics of the precursor, and process parameters (such as temperature and pressure) have a significant impact on the uniformity of the final pore structure and the closed-cell ratio. Common issues include wide pore size distribution and structural inhomogeneity. Therefore, it is necessary to combine the use of nucleating agents and external field regulation (such as microwave assistance, blade coating foaming, and pressure control) to optimize the pore structure.

In terms of modification, researchers have improved cell uniformity and closed-cell structure by optimizing polymer chain structures, introducing nucleating agents (such as chopped glass fibers), and increasing the solubility of blowing agents (such as fluorinated PI). Microwave-assisted foaming and stepwise heating and insulation strategies also help enhance the control precision of the foaming process.

Although the bubble-like structure PI has good mechanical strength and environmental resistance, its thermal insulation performance is generally lower than that of channel-like structures, and the material density is relatively high, which presents certain disadvantages in lightweight applications.

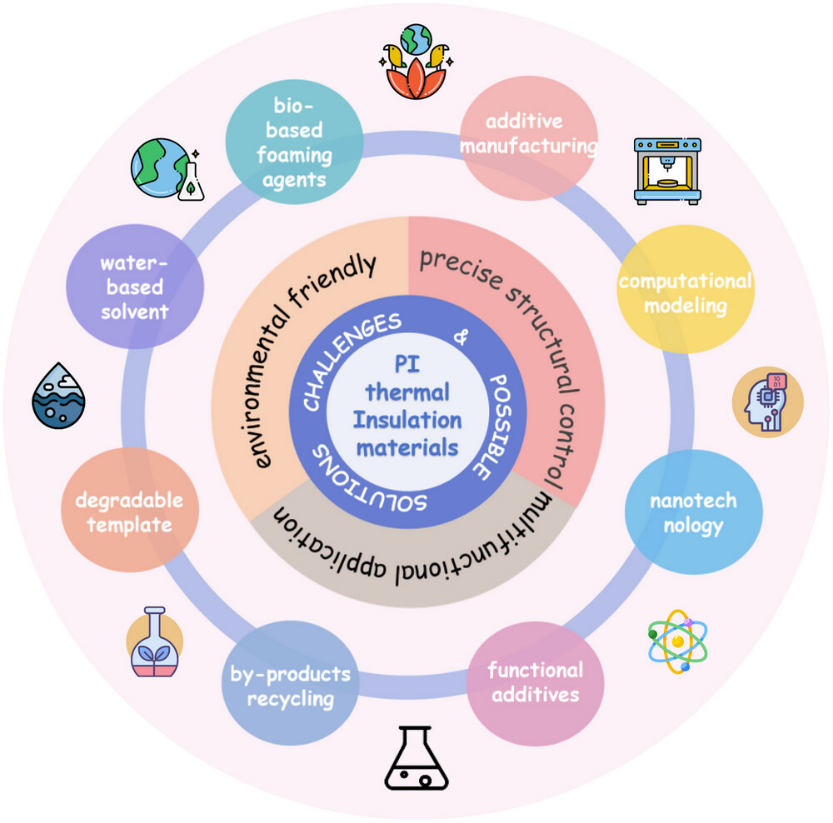

4 Conclusion and Outlook

Based on pore structure characteristics, PI thermal insulation materials are divided into two categories: "channel-like" and "bubble-like." This paper systematically elaborates on their heat transfer mechanisms, preparation methods, performance characteristics, and modification strategies. The channel-like structure exhibits superior thermal insulation performance but has relatively poor mechanical strength and stability; the bubble-like structure possesses good mechanical properties but relatively lower insulation efficiency.

Current research mainly focuses on enhancing the comprehensive properties of PI materials through multi-scale modification methods. Future key development directions include:

-

Develop green preparation processes to reduce the environmental impact of traditional synthesis and foaming processes.

-

Integrating nanotechnology, additive manufacturing, and computational design methods to achieve precise control and multifunctional integration of porous structures.

-

Expanded materials are applied in aerospace, electronic devices, and building energy conservation fields to meet composite requirements such as high insulation, high strength, and resistance to extreme environments.

Through innovations in materials and processes, PI-based insulation materials are expected to play a more significant role in achieving global energy-saving goals and promoting the development of high-tech industries.

Figure 17. Schematic diagram of prospects for polyimide thermal insulation materials. Note: The chart is from the original text and the version belongs to the original author.

Source: Adv. Funct. Mater. 2025, e10818, DOI: doi.org/10.1002/adfm.202510818.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track