How Far Has the Satellite Chemical Alpha-Olefin Project Progressed?

The satellite chemical alpha-olefin project is a landmark engineering feat in the field of new chemical materials in China. Its technological breakthroughs and industrial progress have not only broken foreign monopolies but also propelled China from being a "low-end polyolefin producer" to a "high-end material innovator."

The project has now entered the peak construction period, and after the first phase is put into production in 2026, Satellite Chemical is expected to become one of the world's largest α-olefin suppliers, driving Lianyungang to develop a new materials industry cluster worth hundreds of billions.

The technical breakthrough of Satellite Chemical's α-olefin project began in 2018 when the company officially launched the pilot-scale technology development for high-carbon α-olefins. After five years of research and development, in February 2023, the industrial trial plant with a capacity of a thousand tons of α-olefins was successfully put into operation on the first try. It achieved stable operation and met the predetermined targets by March of the same year. The core achievement of this phase is the independently developed...High Selectivity Production Technology of High-Purity 1-Octene by Tetramerization of EthyleneOn September 17, 2023, through the achievement appraisal organized by the China Petroleum and Chemical Industry Federation, it was recognized that the overall level reached international advanced standards, and the purity index of 1-octene was superior to similar products both domestically and internationally.

The key to technological breakthroughs lies inCatalyst innovation Process optimizationThe new metal catalyst developed by Weixing Chemical has achieved high selectivity in the production of 1-octene (purity >99.2%). Through independently designed equipment, it has solved the challenges of efficient product separation and long-term operation of the reaction system. This technology fills a domestic gap and lays the foundation for the construction of subsequent 10,000-ton industrial-scale installations.

In June 2023, Satellite Chemical officially announced.Alpha-Olefin Integrated Utilization High-end New Materials Industrial Park ProjectThe total investment is 26.6 billion yuan, and the project is located in the Xuwei New Area of Lianyungang. It will be constructed in two phases. The project uses ethane as a raw material to achieve low-carbon production through an integrated light hydrocarbon platform, and extends downstream to produce high-end polyolefins, POE (polyolefin elastomers), PAO (poly α-olefins), and other new materials. Additionally, the by-product hydrogen will be utilized to reduce carbon emissions.

On July 18, 2024, Satellite Chemical stated in a conference call that the first phase of the alpha-olefin comprehensive utilization high-end new material industrial park project has already commenced construction and is progressing smoothly. It is expected to be mechanically completed by the end of 2025 and put into operation in early 2026. The second phase of the project is expected to complete various formalities in the second half of this year and be completed by the end of 2026. Once completed, the project will further enrich the company's downstream industrial chain and help address the current shortage of high-end chemical new materials in China.

The first phase of Company α's high-end industrial park project for comprehensive utilization of olefins has placed orders for six ethane carriers in July 2023. These vessels are expected to be delivered in early 2026, aligning with the construction schedule of the project's first phase. Ethane carriers for the second phase are also under negotiation and will be matched to meet the operational needs of the second phase facilities.

On the same day, Satellite Chemical stated on its stock interaction platform that the company’s alpha-olefin products include C4, C6, and C8. The process packages for the 100,000-ton C8 and C6 units have been completed; C4 has completed pilot testing, and the process package for the 50,000-ton unit is currently being prepared. The industrial-scale facilities for the above products are expected to commence construction in the fourth quarter of this year and be completed by the end of 2025. These will meet the company’s raw material needs for polyethylene, POE, and other units, further enhancing the company’s integrated industrial chain advantages. The performance of the pilot POE products has reached international standards, and the project is progressing well. The process package for the 100,000-ton unit is being prepared, with the aim of starting construction of the industrial facility by the end of this year and completing it by the end of 2025.

Phase 1 constructionThe project (with an investment of 12.15 billion yuan) includes two sets of 100,000 tons/year α-olefin units and a 900,000 tons/year polyethylene unit, etc. It was launched in June 2024, with completion planned for the end of 2025 and production scheduled to start in early 2026. As of July 2025, long-lead equipment orders have been completed, and the project is progressing according to plan.Phase II construction(With an investment of 14.45 billion yuan) including three sets of 100,000 tons/year α-olefin units, three sets of 200,000 tons/year POE units, etc., and it is planned to be completed by the end of 2026.

Of note is that Satellite Chemical is simultaneously advancing.Pilot Test of Polyethylene Elastomer (POE)In May 2025, the approval was granted for the construction of a 500-600 tons/year pilot plant to gain experience for large-scale POE production. Additionally, the company has applied for several patents, such as the "Polyethylene Elastomer Process Tail Gas Treatment Device," to further optimize the production process.

On July 16, 2025, the environmental impact assessment for the polyethylene elastomer industrial pilot plant project of Lianyungang Petrochemical Co., Ltd. was accepted!

In March 2025, the company was granted the invention patent for the "Preparation Method of High Carbon α-Olefins" (CN202411370970.0). This technology utilizes a supported PCNSiP coordination-type metal complex catalyst to achieve high-activity and high-selectivity oligomerization of ethylene, addressing the issues of high cost and low selectivity associated with traditional processes.

On February 13, 2025, Satellite Chemical issued the first environmental impact assessment announcement for the polyethylene elastomer industrial test unit project of Lianyungang Petrochemical Co., Ltd.

α-olefins are core raw materials for high-end polyolefins and new energy materials. Domestic 1-octene has long been reliant on imports, with imports accounting for over 90% of consumption in 2023. After the commissioning of the Satellite Chemical project, the first phase with a production capacity of 100,000 tons per year of α-olefins will prioritize meeting domestic demand in fields such as POE and high-end polyethylene, and is expected to replace 30% of imports.

In downstream applications,POEIt is a core growth point. With the explosion in demand for photovoltaic encapsulation films, the domestic POE gap is expected to reach 800,000 tons by 2025. Satellite Chemical plans a POE production capacity of 600,000 tons per year, which will synergize with its self-produced α-olefin capacity to capture the new energy materials market. In addition, products such as PAO (lubricant base oils) will also enter the high-end industrial sector.

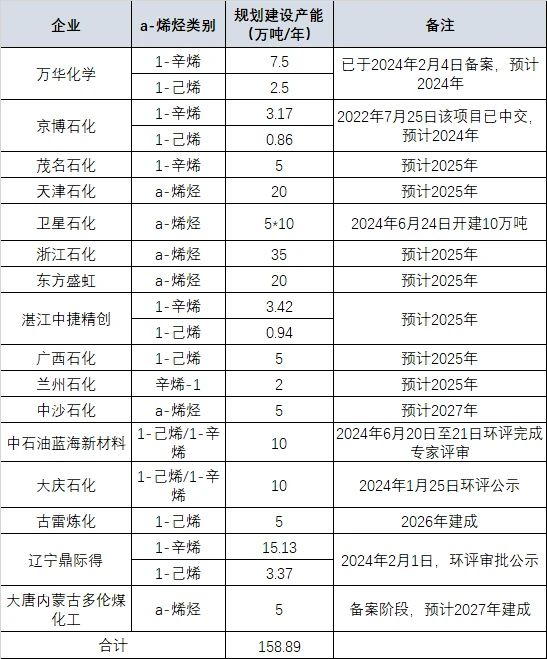

In recent years, major domestic companies have been investing in α-olefin projects, and α-olefins are gradually becoming a competitive field for large companies. The statistics of domestic α-olefin production capacity under construction and planning are as follows:

Source: China Chemical Industry Parks (2024 Statistics)

Amid the intensifying competition in the domestic ethylene industry, Satellite Chemical's alpha-olefin project demonstrates multidimensional advantages.

Raw material and cost advantages: Utilizing the ethane feedstock route, characterized by high yield and low cost, aligns with the requirements for green and low-carbon transformation. By leveraging the Orbit platform, co-operated with ET, stable ethane supply is ensured. Furthermore, after the lifting of the U.S. ethane export restrictions in early July 2025, supply chain risks will be completely eliminated. (On July 9th, Satellite Chemical stated in response to investor concerns: Currently, the planning of process production lines using ethane as raw material is relatively limited globally, due to restrictions on U.S. ethane pipelines and export facilities, which require dedicated ethane transport ships. The company's advantage lies in possessing proprietary ethane pipelines and export facilities, built in a joint venture with suppliers. Additionally, the company has established a mature fleet of ethane transport ships. These conditions are currently unique advantages of the company.)

Industry Chain Synergy Advantage: The project extends downstream to deploy 1.7 million tons of high-end polyolefin (including metallocene polyethylene), 600,000 tons of polyethylene elastomer (POE), and 30,000 tons of poly-alpha-olefin, forming an integrated "alpha-olefin-POE" industry chain. The Lianyungang base, as one of the seven major national petrochemical industry bases, possesses significant locational and supporting advantages.

Green and Low-carbon Empowerment: Introducing the "Heping No. 1" nuclear energy steam supply project by China National Nuclear Corporation, significantly reducing steam costs and carbon emissions. The project is also equipped with CO₂ capture and utilization and a by-product hydrogen resource system, achieving carbon reduction and new energy synergistic development. Future plans aim for an annual hydrogen production capacity of 400,000 tons, targeting to become the largest hydrogen supplier in East China.

In international competition, Satellite Chemical'sEthane feedstock advantage Technological barriersThe core competitiveness is formed. The company has secured low-cost raw material supply by signing a lease agreement with EPS for 12 ethane carriers, and the high selectivity of the ethylene tetramerization technology (with 1-octene accounting for 70%) makes its products superior in purity and cost compared to international giants like Chevron Phillips.

As the completion milestone of the first phase of the project approaches by the end of 2025, Satellite Chemical's α-olefin project has entered a critical stage of construction. The successful commissioning of the project will advance China's technological sovereignty in key material areas such as POE and high-carbon α-olefins, providing solid material support for strategic industries like photovoltaics and new energy.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track