Green innovation, safe navigation | clariant exolit™ op flame retardants accelerate upgrading of engineering plastics

The 11th Engineering Plastics Innovation Application Forum 2025 was successfully held in Shenzhen recently. This forum focused on popular fields such as automotive, electronics and electrical, and communication materials, discussing and exchanging ideas on topics like cutting-edge technologies, innovative applications, and sustainable development of essential engineering plastic materials, injecting new ideas and new momentum into industry development.

As a specialty chemicals company focused on sustainability,Clariant was invited to attend and delivered a speech titled "Clariant Halogen-Free Flame Retardant Materials: Green Innovation, Safe Protection."Clariant has focused on sharing how its innovative halogen-free flame retardant solution, Exolit™ OP, supports the new energy vehicle and electrical and electronics industries in moving towards a safer and greener future.

Engineering plastics accelerate upgrading.

Flame retardants face multiple challenges.

Driven by multiple factors such as application scenario expansion, supply chain fluctuations, and stricter environmental regulations, the engineering plastics industry is rapidly developing towards high performance and green sustainability. This trend demands higher performance and environmental requirements for flame retardants, such as high pressure and high temperature resistance.

Application Scenario Expansion

With the widespread adoption of 800V fast-charging applications and the further deployment of unattended home appliances, materials are...CTITracking IndexHigh GWIT(Hot wire ignition temperature) requirementClariant #Exolit™ Non-Halogenated Flame RetardantThe advantages in this area have been fully demonstrated.

Supply chain fluctuations

Due to the soaring cost and unstable supply of antimony trioxide, a synergist in brominated flame retardant systems, the competitiveness of halogen-free flame retardant formulations is increasingly growing.This trend has also driven the increased demand for halogen-free flame retardants in nylon and polyester.。

At the same time,To enhance the sustainability of engineering plastics.The industry is graduallyReduce PTFEThe use as an anti-dripping agent, which is a common anti-dripping agent in the bromine-antimony composite flame retardant system. This environmental trend also promotes...Halogen-free flame retardant formulations containing Exolit™ are being used more widely in nylon and polyester.Because Exolit™'s halogen-free flame retardant formulation inDoes not drip when burningNo additional anti-dripping agent is needed.

Clariant's Halogen-Free Flame Retardant Solutions

Green innovation, safe navigation

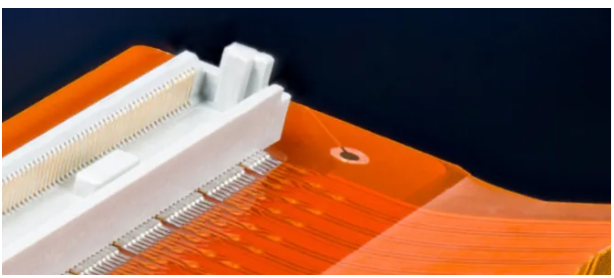

Clariant's Exolit™ OP innovative non-halogen flame retardant solutions were invented by Clariant and are protected by patents.Halogen-free phosphorus-containing polyols and organic hypophosphites have gained wide recognition in engineering plastics such as nylon and polyester, as well as in some epoxy-based thermosetting applications.

Exolit™ OP==Pass the UL 94 vertical burning test.SampleAchieves V-0 rating even with a thickness as low as 0.4 mm.At the same time, Exolit™ OP has excellent properties.Thermal stability, mechanical properties, and electrical propertiesIt can provide efficient flame-retardant protection that meets performance requirements and environmental challenges for fields such as electronics and electrical, transportation, and household appliances.

To address increasingly stringent technical standards and regulatory requirements.Clariant continues to introduce innovative solutions for the electronics, electrical, and electric vehicle sectors.Among them,Exolit™ OP 1242 (TP) Exolit™ OP 1266 (TP)Solved two key challenges in the application of PBT in the fields of electronics, electrical appliances, and electric vehicles: hydrolysis resistance and high CTI (Comparative Tracking Index).

High GWIT New Products

Exolit™ OP 1380 / OP 1480 / OP 1466

Developed specifically for nylon systemsThe material containing this series of products can pass the glow-wire test (GWIT) with a requirement of ≥800°C, meeting the flame-retardant and high-temperature resistance needs of unattended household appliances.

Hydrolysis-resistant new product:

Exolit™ OP 1242 (TP)

Specifically developed for polyesterIt can provide excellent hydrolysis stability and is typically used in PBT GF and PET GF along with nitrogen synergists to achieve better flame retardant effects.

High CTI New Products

Exolit™ OP 1266 (TP)

Developed specifically for polyesterComposite materials containing Exolit™ OP can achieve a comparative tracking index (CTI) of 600 V and above. Capable of meeting the stringent high CTI performance requirements in the electric vehicle field.Achieve miniaturization and complex design.

With the full commissioning of the second flame retardant production line at the Daya Bay plant, Clariant has further enhanced its ability to serve the local and Asian markets.Especially in the fields of electric mobility, electronic and electrical applications, 5G communications, etc.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories