Finally, someone explains "pvc heat stabilizer" clearly!

Engineers working on PVC formulations all say, "Thermal stabilizerTake it to heart.

From extruded profiles to injection molded fittings, from transparent sheets to flexible cables.Without heat stabilizers, PVC might "die" in the barrel and not even make it out of the machine.。

What is it about this seemingly "auxiliary" material that can determine the "life or death" of PVC? How does it protect PVC molecules from breaking down in the "crucible" of high-temperature processing? And how does it affect the final product's color, transparency, weather resistance, and lifespan?

Why does PVC rely on heat stabilizers for "life extension"?

Imagine: you are extruding a white, smooth window frame profile, with the temperature controlled at 190°C.

Suddenly, the product surface started to turn yellow, followed by black spots appearing, and eventually even bubbling and cracking...

The entire production line was forced to shut down, the screw was cleaned, and the raw materials were scrapped—resulting in significant losses.

The root of all this is that PVC is inherently "afraid of heat."

The molecular chain of PVC contains chlorine atoms, which can easily detach under the influence of heat.Initiate chain dehydrochlorination reaction.

- Allyl chloride (-CH₂-CHCl-CH=CH-)The C-Cl bond energy is 30% lower than that of ordinary chlorine, akin to a "weak weld point" on the molecular chain; like a "loose screw" in a chain, when the temperature exceeds 140°C (such as during processing in extrusion or injection molding), the chlorine atom here will jump out like a flea being scorched, leaving behind an "unsaturated double bond."

- Sec-chloro group:The chlorine atom at the branching point is more likely to detach, forming an active site. Similar to a "crooked link" in a chain, it can be easily "pried open" by oxygen or ultraviolet light, even if the temperature is not very high, releasing HCl.

Like toppling a domino, once it starts, it rapidly spreads, leading to molecular chain breakage, cross-linking, discoloration, and even carbonization.

The heat stabilizer is the guardian that promptly "calls a halt" on the high-temperature battlefield.

1. What exactly is a PVC heat stabilizer? The "fire brigade" and "structural reinforcement expert" of the microscopic world.

The essential task of a heat stabilizer, disregarding chemical terminology, is:Prevent PVC from decomposing during processing and use.

They operate through the following mechanisms, like a well-coordinated emergency rescue team:

1. Absorb HCl and interrupt the chain reaction.

The decomposition of PVC releases hydrogen chloride (HCl), which accelerates its own decomposition, creating a self-catalytic effect.

The alkaline components in heat stabilizers (such as soaps of calcium, zinc, and lead) can quicklyAbsorb HClTo prevent the reaction from continuing to spread.

Replace unstable chlorine atoms to fundamentally "defuse the bomb."

There are some "weak links" in PVC molecules, such as allyl chloride and tertiary chloride, which are prone to decompose first.

High-quality heat stabilizers (such as organotin, zinc-based) canActively replace these unstable chlorine atoms.Introduce a more stable chemical structure to fundamentally prevent the initiation of decomposition.

Capture free radicals and block oxidation pathways.

Under high temperatures, PVC can undergo oxidative degradation, producing free radicals.

Certain stabilizers (such as phosphites, epoxides) can Capture these free radicals.Block the oxidation chain reaction.

Neutralize metal ions to prevent catalytic degradation.

Residual metal ions in the raw materials (such as iron and zinc) may catalyze degradation.

Some stabilizers canComplex these metal ions.This reduces its catalytic activity.

2. Only when this "guardian" steps in can PVC remain "steady as an old dog"!

PVC without heat stabilizers is like a person under the scorching sun without sunscreen—it quickly "burns," "ages," and "collapses."

An efficient thermal stabilization system can play a key role in the following aspects:

✅ Processing stability: Ensure smooth PVC forming

Prevent yellowing, black spots, and bubbles during the processing.

- Extend the melt stability time, allowing for a wider processing window.

Reduce downtime for mold cleaning and improve production efficiency.

✅ Product Appearance and Color Control

- Maintain the initial whiteness or transparency of the product

To prevent discoloration caused by heat and light during later use.

✅ Long-term weather resistance and lifespan

To slow down ultraviolet degradation during outdoor use

- Maintain mechanical properties, prevent embrittlement and pulverization.

✅ Environmental Protection and Health Safety(Especially for lead-free systems such as calcium-zinc and organotin)

- Substitute lead salt stabilizers to meet RoHS, REACH, and other regulatory requirements.

Suitable for high-end fields such as food contact, medical devices, and children's toys.

3. As a formulation designer, how do you choose and blend this "guardian"?

The heat stabilizer is not a "lone hero," but aCooperative combat system.

You need to accurately match according to product performance requirements, processing technology, cost budget, and even environmental regulations.

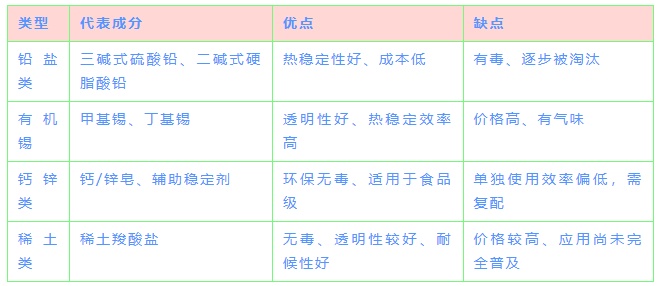

🔧 Main Types of Heat Stabilizers and Their Characteristics:

🧩 Compound Strategy: Synergistic Effect of 1+1>2

Few people use only one stabilizer. Compound formulation is the essence of technology.:

- Primary stabilizer + Auxiliary stabilizer:

Calcium-zinc + epoxidized soybean oil + phosphite synergistically enhance thermal stability.

Internal and external lubrication balance:

Many stabilizers themselves also have lubricating effects (such as calcium stearate and lead salts) and need to be used with external lubricants (such as PE wax) to prevent precipitation.

The addition of antioxidants and UV absorbers:

Further enhance long-term thermal-oxidative stability and weather resistance.

4. Conclusion: Heat stabilizers are by no means "supporting actors"!

We debug PVC formulations, optimize processing techniques, and enhance product performance to a great extent.Dancing with a thermally stable system。

It is not only the "lifesaver" for PVC processing, but also the "guiding star" for product performance.

Yellowing, black spots, degradation, and embrittlement during production—tracing back to the source, many issues stem from improper selection or formulation of the thermal stabilization system.。

When facing the development or problem analysis of a PVC product next time, why not ask one more question:

“Is my heat stabilizer the right choice? Is it sufficient? Is it synergistic?”

Understanding this "high-temperature guardian" gives you another key to mastering PVC material design.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics