Effects of Glass Fiber Content on the Flame Retardancy of Halogen-Free Flame Retardant Glass Fiber Reinforced PP

Glass fiber reinforced polypropylene (PP/GF) has the advantages of low density, good heat and creep resistance, and high cost-effectiveness. It is currently widely used in electronics, aerospace, and automotive industries to produce lightweight and thin-walled components as a replacement for steel, engineering plastics, and other materials.

The limiting oxygen index (LOI) of PP is approximately 17.0%, classifying it as a flammable material. During combustion, it produces a large amount of flaming molten droplets and releases a considerable amount of heat. Although the addition of GF significantly suppresses the molten droplet phenomenon, due to the "wick effect" of GF, the material exhibits a prolonged burning duration and high heat release. In applications with stringent requirements, flame retardant treatment of PP/GF is necessary. In recent years, some bromine-antimony flame retardant systems have been found to produce toxic smoke during combustion. Relevant laws and regulations domestically and internationally have prohibited the use of brominated flame retardants such as decabromodiphenyl ether.

The phosphorus-nitrogen intumescent environmentally friendly halogen-free flame retardant system has advantages such as eco-friendliness and low cost, and has been practically applied in the field of polyolefin materials. For example, piperazine pyrophosphate (PAPP) contains phosphorus and nitrogen elements and has a high hydroxyl content, which can serve as an "acid source" and "carbon source" in intumescent flame retardant systems. This paper investigates the effect of GF content on the performance of PP/GF materials by compounding PAPP with MPP to form a piperazine pyrophosphate intumescent flame retardant, while keeping the amount of flame retardant constant.

The effect of GF content on flame retardancy

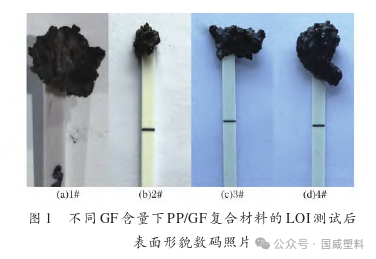

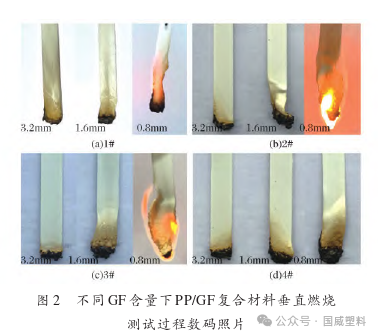

From Figure 1 and Figure 2, it can be observed that an intumescent char layer is present on the surface of the samples in both the LOI test and the vertical burning test, indicating that the flame retardant functions by forming a char layer through solid-phase intumescence.

With the same amount of flame retardant, the flame retardancy of PP/GF material is improved with the increase in GF content (GF < 30%).

On one hand, as the GF content increases, the content of the PP matrix relatively decreases, resulting in fewer combustible fragments produced from the matrix during LOI testing. At the same time, with the increase of GF content, the melt flow rate of the material decreases, which helps to improve the dripping phenomenon in thinner samples and makes it easier to pass the vertical burning test. On the other hand, the flame retardant works through a "solid-phase charring" mechanism, and its char layer is well coated on the surface of the specimen, not being "pierced" by the high-temperature residue of GF. The formed insulating and oxygen-isolating protective layer can reduce the release of combustible substances, thereby providing a good flame-retardant effect.

The Effect of GF Content on Thermal Stability

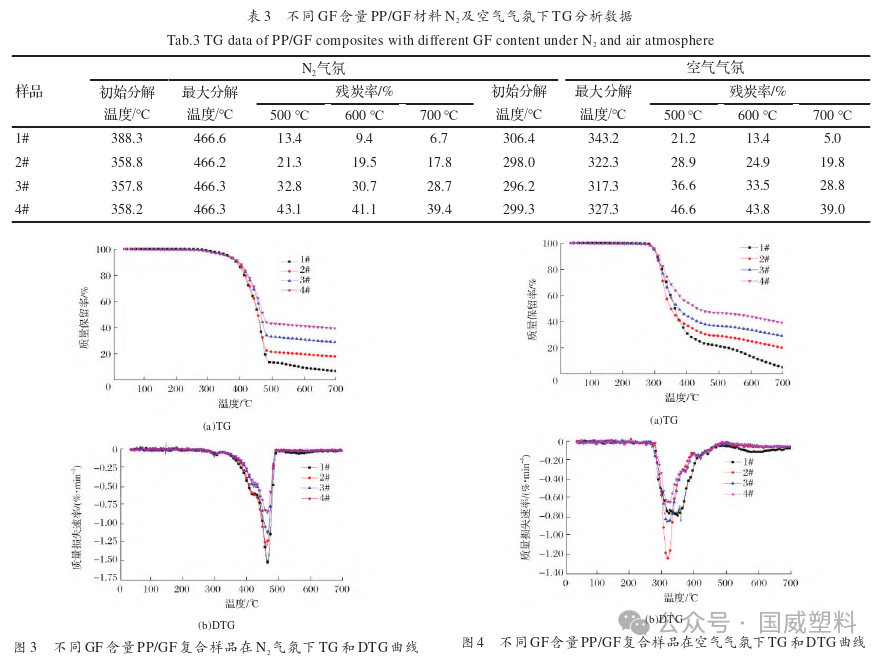

After the addition of GF to polymer materials, various physical properties of the materials are improved, such as dimensional stability and heat distortion temperature. TG analysis can provide various thermal decomposition parameters of polymer materials under anaerobic or aerobic conditions, which plays an important role in studying the flame retardant mechanism of the materials.

After the addition of GF, the residual carbon rate during the high-temperature stage increases with the increase of GF content. When the GF content increases to 25%, the residual carbon rate of sample #4 at 700 ℃ increases to 39.4%, indicating that the combustible gases generated by the sample at high temperatures decrease, mainly forming non-combustible solid carbides. As can be seen from Table 3 and Figure 4, in an air atmosphere, the material undergoes thermo-oxidative degradation under the action of oxygen. The initial decomposition temperature of the control sample #1 is reduced to 306.4 ℃ compared to a nitrogen atmosphere, while the initial decomposition temperature of samples #2 to #4 also decreases to around 298℃ compared to a nitrogen atmosphere. The main weight loss interval is between 300 to 500℃. In the early stage, the thermo-oxidative decomposition of the base material PP occurs along with the decomposition and weight loss of the flame retardant. In the high-temperature stage, the carbon layer undergoes further oxidative decomposition with the participation of oxygen. During the high-temperature stage, the residual carbon rate of samples with different GF contents is higher than that of sample #1, mainly because GF is not easily decomposed at high temperatures.

Overall, the addition of GF reduces the initial thermal decomposition temperature of flame-retardant PP/GF composites, but improves the thermal stability of the material at high temperatures.

Effect of GF Content on Combustion Performance

Under external thermal radiation, the flame retardant FR-1420 expands into a carbonaceous layer, forming an insulating protective layer on the sample surface. After testing, the char layer expansion thickness of sample #1 (control) is approximately 2.5 cm. Compared to sample #1, the char layer expansion thickness of sample #2, which contains 15% GF, increases to about 6.2 cm.

As the GF content increases, the expansion thickness of the char layer decreases, with the expansion thickness of the char layer of sample #4 reduced to about 5.0 cm. This is because, on one hand, GF is relatively stable at high temperatures, and the high-temperature residues of GF act as a "char layer skeleton" during the expansion of the char layer. Therefore, the addition of GF is conducive to the increase in char layer expansion thickness. On the other hand, when the GF content is high, the larger amount of high-temperature residues also inhibits the expansion of the char layer, resulting in a gradual decreasing trend in the expansion thickness of the char layer.

The addition of GF did not affect various combustion parameters of the material, such as the peak heat release rate (PHRR), indicating that the material has good fire safety. Furthermore, the addition of GF as an inert fiber reduces the relative content of the base material PP, leading to a reduction in combustible substances in the gas phase during combustion. At high temperatures, the solid phase is composed of non-combustible residues. The material's residue-weight versus time curve indicates that the residue weight is higher in the high-temperature stage after the addition of GF, resulting in lower amounts of combustible gaseous substances. Consequently, the heat release and smoke production during combustion are reduced. Additionally, the inclusion of GF did not affect various fire safety indices of the material, such as the ratio of PHRR to the time to reach PHRR, which is the fire growth rate index (FIGRA), or the maximum average heat release rate (MAHRE), all of which remained largely unchanged.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track