Dry TipsAutomotive Interior Color Masterbatch Formulation Design Guide

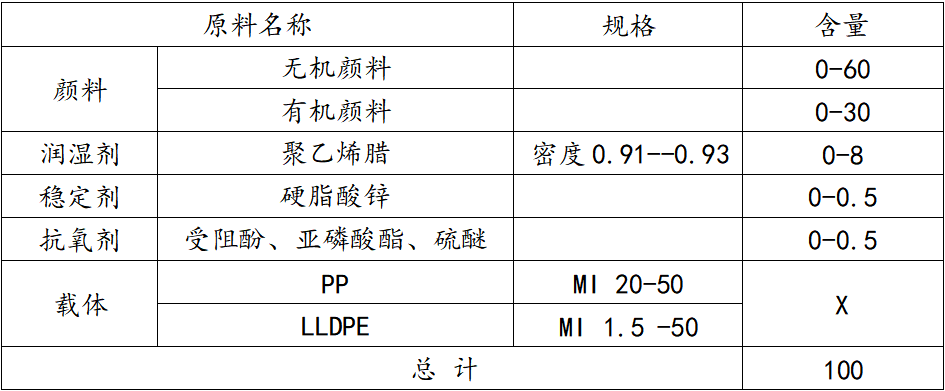

The appearance and performance of automotive interior parts largely depend on the formulation design of color masterbatches. These polypropylene-based color masterbatches must not only meet visual requirements such as high gloss and no metamerism but also strictly control VOC content to suit the special usage environment of automotive interiors. The formulation design for color masterbatches used in automotive interior colored parts is shown in Table 4-21.

Table 4-21 Blow Molding Film Grade Masterbatch Formulation

This article will focus onDesign of Color Masterbatch Formulation for Automotive Interior PartsThe core points are to break down the key technologies in industrial production from the following aspects, providing practical reference for industry practitioners.

1. Isotachochromism

2. Glossiness

3. Colored Composite Inorganic Pigments

4. Carbon Black Applications

5. VOC Control

01Metamerism

The greatest challenge for plastic masterbatch used in automotive interior colored parts is to avoid metamerism.

It requires achieving the matching of different plastic color samples and the same color target under multiple light sources. Every object's color has its unique spectral reflectance curve. When this object reflects visible spectra under a specified light source to the observer, it produces spectral tristimulus values.

When the spectral tristimulus values of two objects with different spectral reflectance curves are equal, the two objects are considered conditionally metameric.

Once the light source changes, the spectral tristimulus values generated will differ due to the different energy distributions of each source, resulting in the phenomenon of metamerism.

Most automotive OEMs choose the D65 and F11 light sources as the basis for determining metamerism.

To avoid metamerism, firstExtensively collect pigment data,Establish a computer databaseadoptComputer-Aided Color Matching TechnologyIf manual color matching is used, it is necessary to compare automotive pigments and perform reflection spectrum analysis, which places high demands on the colorist.

02Glossiness

As we all know, car colors are generally dominated by cool tones such as beige, gray, brown, and black. Different shades of beige, gray, and black are named after their unique color codes, such as Y20 (gray), 95T (beige), 82V (black), and 9B9 (black). We refer to these as standard color panels, with each color code representing a set of L, a, b values.Color determination of general automotive interior parts is usually performed using a spectrophotometer and comparing the color difference against a standard color chart.Under different light sources (D65 light source, F11 light source), the color difference ranges vary for different color codes. For specific details, please refer to the interior color evaluation standards of various OEMs, such as Volkswagen's VW50190.

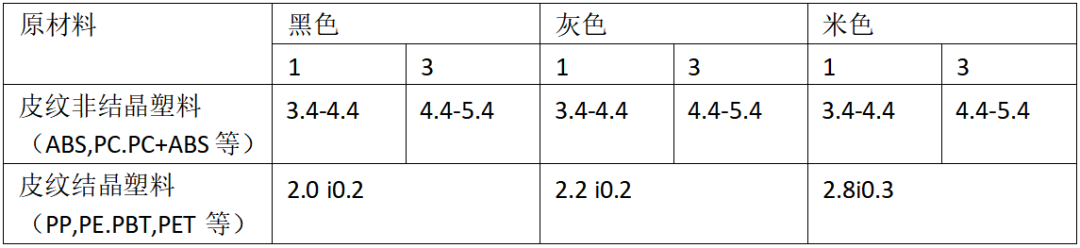

In addition, the quantification of color is often closely related to mold texture, glossiness, and other factors. Table 4-22 shows the glossiness requirements for various interior materials under different colors.

Table 4-22 Glossiness Requirements for Various Interior Materials

General glossiness exceptThe gloss characteristics of the raw material itselfMoreover, also byDispersant types in color masterbatch formulations,Injection molding process mold temperature,Surface glossiness of injection molding moldsAs decided.

03Colored composite inorganic pigment

Given that the color tone of automotive interior trim parts is mainly light colors, such as beige and light gray, colored composite inorganic pigments are the preferred choice of pigments.It is a doped crystal formed by one or several metal ions doped into the lattice of other metal oxides. The doped ions cause special interference with the incident light. Certain wavelengths are reflected while the rest are absorbed, making it a colored pigment. In other words, various metal oxides are uniformly distributed within the lattice of the new chemical compound, similar to a solution but in a glass-like solid state. Chemically, it can be regarded as a stable solid solution. Therefore, it possesses excellent durability, high hiding power, superior heat resistance, light resistance, weather resistance, chemical resistance, as well as high infrared reflection performance and partial ultraviolet shielding capability. It can improve the weather resistance, light resistance, and thermal insulation of plastic products, thereby extending the product's service life.

The rutile lattice of colored composite inorganic pigments incorporates nickel oxide, chromium(III) oxide, or manganese oxide as chromophore components. Elements such as nickel, chromium, manganese, and antimony in these rutile-type pigments fill the original crystal defects in titanium dioxide, resulting in a more complete crystal structure and enhancing the stability of the crystal lattice.

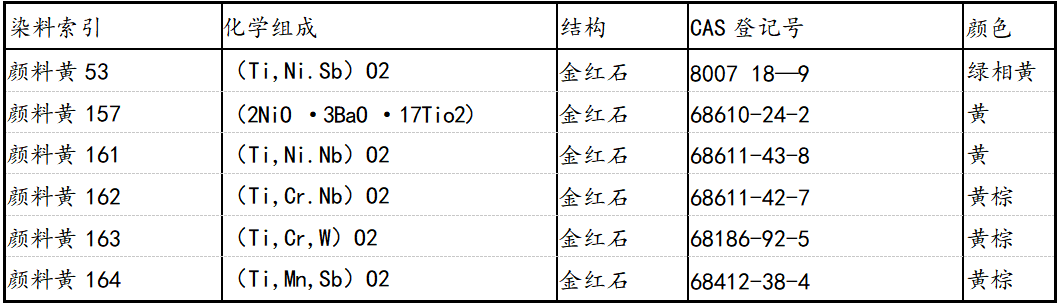

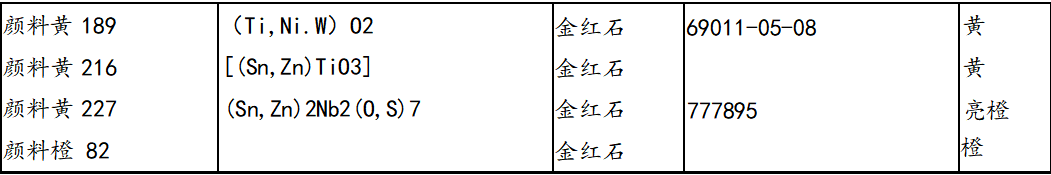

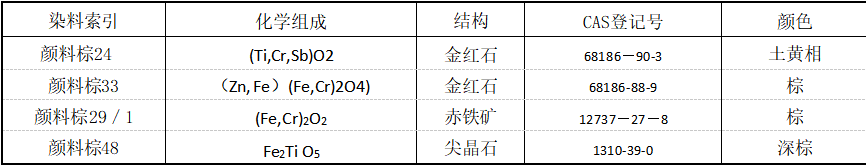

These metallic elements have lost their original chemical, physical, and physiological properties. Therefore, this type of rutile pigment cannot be considered as compounds of nickel, chromium, or antimony, or their simple oxides. The mixed-phase metal oxide pigments are highly inert, with a hot water leaching amount below 2 ppm, and cannot be dissolved by human stomach acid, thus even if ingested into the gastrointestinal tract, they are harmless to the human body; contact with them is also absolutely safe. For this reason, they are not classified as hazardous substances. According to the manufacturer's instructions on compatibility, purity, and safe handling, most of these pigments are considered non-toxic and meet the requirements for food contact as well as toy safety regulations. The main varieties of yellow are listed in Table 4-23, and the main varieties of brown are listed in Table 4-24.

Table 4-23 Yellow Mixed-Phase Metal Oxide Titanium-Based Inorganic Pigment Varieties

Table 4-24 Brown Mixed Metal Oxide Titanium-Based Inorganic Pigments

04

For automotive parts or household appliances, gray or light gray is often chosen, so the selection of carbon black is also very important.Carbon black is a type of product generated by the incomplete combustion and pyrolysis of hydrocarbon substances in a reactor. Depending on the raw materials and production processes used, it can be classified as “furnace black,” “lamp black,” “gas black,” “acetylene black,” and “channel black.”

Lamp black, also known as lamp soot black, dates back to ancient China and Egypt. At that time, people burned oil and fat under inverted conical porcelain or clay pots, and the soot deposited on the cool surface of the pots was collected regularly.

Even to this day, this method of production is basically still retained, except that the raw materials used now are petroleum-based or coal tar-based oils. These are burned on a flat iron pan with a diameter of up to 1.5 meters. The combustion gases containing carbon black are collected by an exhaust hood lined with bricks, then passed through bent pipes and fire tubes to reach the deposition apparatus.

To control the characteristics of the produced carbon black, it is necessary to ensure that the raw materials mainly undergo incomplete combustion near the gap between the combustion pan and the exhaust hood. Further inside the pipeline, combustion occurs under oxygen deficiency, leading to thermal cracking and the formation of larger carbon black particles. Due to these reasons, the lamp black exhibits a wide range of particle size distribution, primarily characterized by larger particle sizes.

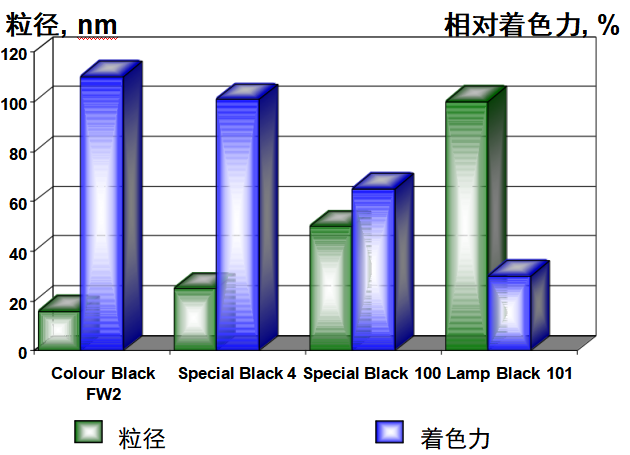

The carbon black formed in the gap between the burner plate and the exhaust hood only has a small portion exposed to oxygen in the air; therefore, these carbon blacks contain only a small amount of surface oxides, corresponding to a neutral pH value, and have very low volatile content, usually less than 1%. Due to the larger particle size of lamp black, its blackness and coloring power are not high, as shown in Figure 4-8.

Figure 4-18 Relationship between Carbon Black Particle Size and Tinting Strength

From Figure 4-18, it is evident that carbon black with a small particle size of 13nm has a tinting strength of up to 110%, carbon black with a small particle size of 25nm has a tinting strength of 101%, while lamp black carbon black with a large particle size of 95nm has a tinting strength of only 30%.

As we all know, gray is generally formulated with a large amount of titanium dioxide and a small amount of carbon black. This is especially true for automotive parts or household appliances, where gray or light gray is often chosen, and a high degree of color difference accuracy is required (ΔE<0.5, with limited values for L, a, and b).Since only a small amount of carbon black is added when preparing gray, errors caused by measurement are easily transferred, making it difficult to control color differences in the product. Therefore, selecting carbon black with low tinting strength can achieve better results with less effort.For example, Lamp Black 101 from Germany's Orion company has a relatively large particle size of 95 nm, a surface area of 20 m²/g, and a pH value of 7.5. It offers good blue undertone and dispersibility, making it the preferred colorant for blending gray shades. During large-scale production, it can reduce the impact of dosing errors on color stability.

05Functional Additives and Dispersing Additives

The VOCs in automotive plastic color masterbatches mainly originate from functional additives (such as antistatic agents, UV stabilizers, etc.) and dispersing agents.Therefore, choosing the right additives becomes particularly important. In this regard, well-known domestic and international polymer additive suppliers have already improved their products. They have launched a series of additives with better compatibility with polymers, low VOC, no blooming, and non-sticky at high temperatures. Among them, American Cyanate Company and Beijing Tiangang's Tiantang TM T series have both made improvements.

To meet the performance requirements of various automotive components, plastic interior parts of automobiles often undergo modification methods to achieve enhanced strength, toughness, and wear resistance.Therefore, masterbatch is used in full mixed modification granulation. Attention should be paid to the addition ratio and mixing distribution of the masterbatch to ensure that the color difference of the injection molded products after mixed granulation meets the required standards.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics