Different fillers have such discrepant effects on the cti of brominated antimony flame retardant pa6? read this paper to unlock key optimizations

The Comparative Tracking Index (CTI) is a measure of a material's susceptibility to tracking. It is designed to simulate the ability of electronic products to form carbonized conductive tracks due to the accumulation of dust particles over time, condensation of moisture, and other factors during use. The appearance of these conductive tracks can generate sparks when voltage is applied to the circuit, causing the plastic to lose its insulating properties. In unconventional environments, using insulating materials with a low CTI can lead to premature breakdown of electrical equipment, resulting in electrical accidents.

According to standards IEC 60112-2009 and GB/T 4207-2012, the test method for CTI involves placing two electrodes on the surface of the material, applying a certain voltage, and dropping an electrolyte onto the material surface between the electrodes every 30 seconds. The CTI value, which is the maximum voltage value in volts, is determined when the material withstands 50 drops of electrolyte without forming a conductive path and without catching fire.

Nylon 6 (PA6) material has balanced toughness and excellent heat resistance. When used as electrical structural components, PA6 is required to have a UL94 V-0 rating.

Decabromodiphenyl ethane / antimony trioxide (abbreviated as bromine-antimony) compound flame retardant system is an excellent flame retardant for nylon materials. It has a low addition rate, significant flame retardant effect, minimal impact on the mechanical properties of PA6 substrate, and high cost-effectiveness, making it the main halogen-containing flame retardant variety in the nylon 6 system.

The CTI of PA6 resin is greater than 600 V. When a bromine-antimony flame retardant is added at a mass fraction of 10%, the CTI of the material decreases to 275 V. Further increasing the mass fraction of the bromine-antimony flame retardant to 13%-14%, the CTI of flame-retardant PA6 decreases to 250 V. The addition of bromine-antimony flame retardant significantly reduces the CTI of nylon materials, enhancing their flame retardancy when used as components in electrical equipment.

1 Experimental Section

1.1 Experimental Materials

PA6:IM, Kuibyshev Nitrogen;

Fiberglass: T435R, Taishan Fiberglass Inc.

Talcum powder: Liaoning Aihai;

Calcium sulfate whiskers: DL–30, Changzhou Guangwei New Material Technology Co., Ltd.

Compound Antioxidant: Shanghai Jinhai Yabao Fine Chemical Co., Ltd.

Lubricant: Honeywell International Inc., USA.

Decabromodiphenyl ethane: Jinan Taixing Fine Chemicals Co., Ltd.

Antimony Trioxide: Jinan Taixing Fine Chemicals Co., Ltd.

1.2 Experimental Instruments

High-Speed Mixer: SHR10A, Zhangjiagang Baixiong Machinery Co., Ltd.

Twin-screw extruder: SHJ–35A, Nanjing Keya Machinery Co., Ltd.

Injection Molding Machine: MA900, Haitian Plastics Machinery Group Co., Ltd.

Universal Testing Machine: CMT6000, MTS Industrial Systems (China) Co., Ltd.

Impact Testing Machine: JC–15, Chengde Precision Testing Machine Co., Ltd.

Horizontal Vertical Burning Tester: 5402, Suzhou Yangyi Wolchi Testing Technology Co., Ltd.

Tracking Test Apparatus: GP–5265, Suzhou Gaopin Testing Instruments Co., Ltd.

1.3 Sample Preparation

PA6 is dried at 90~100 ℃ for 4~5 hours, then mixed evenly with other raw materials except for glass fibers in a high-speed mixer. The glass fibers are added through the vent of the twin-screw extruder.

All raw materials are melt co-extruded at an extrusion temperature of 220~250 ℃ and a screw speed of 250~350 r/min to obtain modified granules through extrusion pelletizing.

After drying the granules at 90~120°C for 4~6 hours, they are injection molded into standard specimens at an injection temperature of 250~290°C.

1.4 Performance Testing

The specimen shall be conditioned for 24 hours at a temperature of (23±2)℃ and a relative humidity of (50±5)% before testing.

Tensile strength and elongation at break were tested according to ASTM D638-2014, with a tensile rate of 5 mm/min.

The impact strength of a simply supported beam with a notch is tested according to ASTM D6110-2017, using a V-shaped molded notch.

Vertical burning tested according to UL94-2016, test thickness 1.6 mm; combustion residue tested according to ASTM D2584-2018.

CTI value tested according to IEC 60112-2009.

2 Results and Discussion

2.1 The Effect of Different Types of Fillers on the CTI of Flame Retardant PA6

The types of fillers differ, and their microstructures vary greatly. Glass fibers have a cylindrical structure, talcum powder and mica have a flaky structure, glass microspheres have a spherical structure, and calcium sulfate whiskers have a needle-like structure.

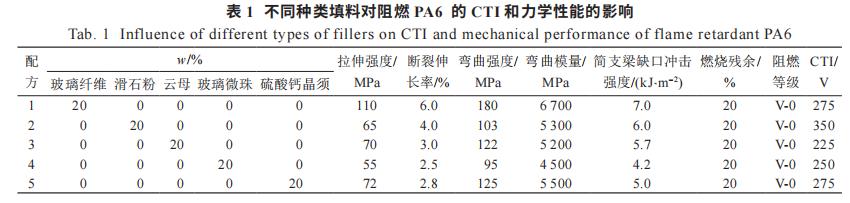

To understand the impact of different microstructures of fillers on the CTI of flame retardant PA6, the mass fractions were fixed as follows: 61% for PA6, 0.5% for antioxidant, 0.5% for lubricant, 14% for decabromodiphenylethane, and 4% for antimony trioxide. The effects of glass fiber, talcum powder, mica, glass beads, and calcium sulfate whiskers on the CTI of flame retardant PA6 were studied. The influence of different fillers on the CTI and mechanical properties of flame retardant PA6 is shown in Table 1.

From Table 1, it can be seen:

Talc-filled flame-retardant PA6 has the highest CTI, reaching up to 350 V.

Next is glass fiber reinforced flame retardant PA6 and calcium sulfate whisker filled PA6, with a CTI up to 275 V.

Once again, it is glass bead-filled flame-retardant PA6, with a CTI reaching 250 V.

The CTI of mica-filled flame-retardant PA6 is the lowest, only 225 V.

Talc powder and mica both have layered structures, but talc powder can improve the CTI of flame-retardant PA6, whereas mica cannot. Talc powder not only has a layered structure, but also the adjacent layers are bonded by weak van der Waals forces. Under the action of external forces, it is easy for adjacent layers to slide or separate from each other, thereby providing a continuous barrier in the material to prevent the development of the carbon layer.

The effect of talc particle size on the CTI of flame retardant PA6

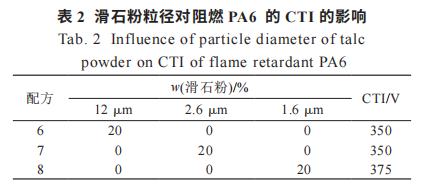

From the experimental results of 2.1, it is concluded that talcum powder has a positive effect on improving the CTI of flame retardant PA6. Therefore, further investigation was carried out on the effect of particle size of talcum powder on the CTI of flame retardant PA6. In the plastic processing industry, the commonly used particle size of talcum powder ranges from 12 to 1.6 μm (1250 to 8000 mesh). The mass fraction is fixed as follows: PA6 at 61%, antioxidant at 0.5%, lubricant at 0.5%, decabromodiphenyl ethane at 14%, and antimony trioxide at 4%. The study examined the effect of talcum powder with three different particle sizes—12 μm (1250 mesh), 2.6 μm (5000 mesh), and 1.6 μm (8100 mesh)—on the CTI of flame retardant PA6. The results are shown in Table 2.

The larger the mesh size of talc powder, the smaller the particle size. As shown in Table 2, as the particle size of talc powder decreases, the CTI of the material tends to increase. When the talc powder particle size is reduced from 12 μm to 2.6 μm, the CTI of flame-retardant PA6 remains at 350 V. When the talc powder particle size is further reduced to 1.6 μm, the CTI of flame-retardant PA6 increases to 375 V.

After twin-screw extrusion, talc is uniformly dispersed in PA6. The smaller the particle size of talc, the more evenly it is distributed in the PA6 matrix, thus serving as a continuous barrier in the material.

Effects of Talc Content on the CTI of Flame Retardant PA6

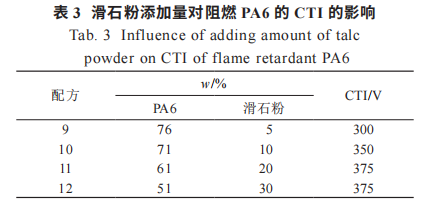

Due to the excessive addition of talcum powder, it is difficult to disperse, which has a negative impact on the mechanical properties of the material, making it less meaningful for practical applications. Therefore, the mass fraction of talcum powder is selected to be 5% to 30%. The fixed mass fraction (antioxidant) is 0.5%, mass fraction (lubricant) is 0.5%, mass fraction (decabromodiphenyl ethane) is 14%, mass fraction (antimony trioxide) is 4%, and 1.6 μm talcum powder is used to further investigate the effect of different amounts of talcum powder on the CTI of flame-retardant nylon. The impact of different talcum powder amounts on the properties of flame-retardant nylon 6 is shown in Table 3.

From Table 3, it can be seen that with the increase in talc content, the CTI of flame-retardant PA6 also gradually increases. When the mass fraction (talc) is 5%, the CTI of flame-retardant PA6 can be increased to 300 V; when the mass fraction (talc) increases to 20%, the CTI can be increased to 375 V. Further increasing the talc content makes its dispersion difficult, prone to agglomeration, and the CTI no longer increases further.

Conclusion

Talc powder can improve the CTI of decabromodiphenyl ethane/antimony trioxide flame-retardant PA6 material.

When the particle size of talcum powder is reduced to 1.6 μm and the mass fraction is 20%, the CTI of flame-retardant PA6 can reach 375 V.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories