Breakthrough in 0-15° Unsupported Metal 3D Printing, Zhongke Xianglong Sets New Industry Benchmark

Introduction: In recent years, many metal 3D printing equipment manufacturers have launched "support-free metal 3D printing" technologies. However, calling it support-free is somewhat inaccurate; it is more appropriate to describe it as using minimal supports. This is because supports are still generally required for angles less than 15°.

Breakthrough in 0-15° support-free printing, breaking industry barriers.

On August 26, 2025, Zhongke Xianglong achieved a major technological breakthrough in the field of Laser Powder Bed Fusion (LPBF) metal 3D printing. The company launched an integrated support-free 3D printing solution for metal materials such as high-temperature alloys and titanium alloys, reducing the limit for support-free printing to below 15°, enabling support-free printing at angles from 0° to 15°, which is equivalent to completely support-free printing, setting a new industry benchmark for technological advancement.

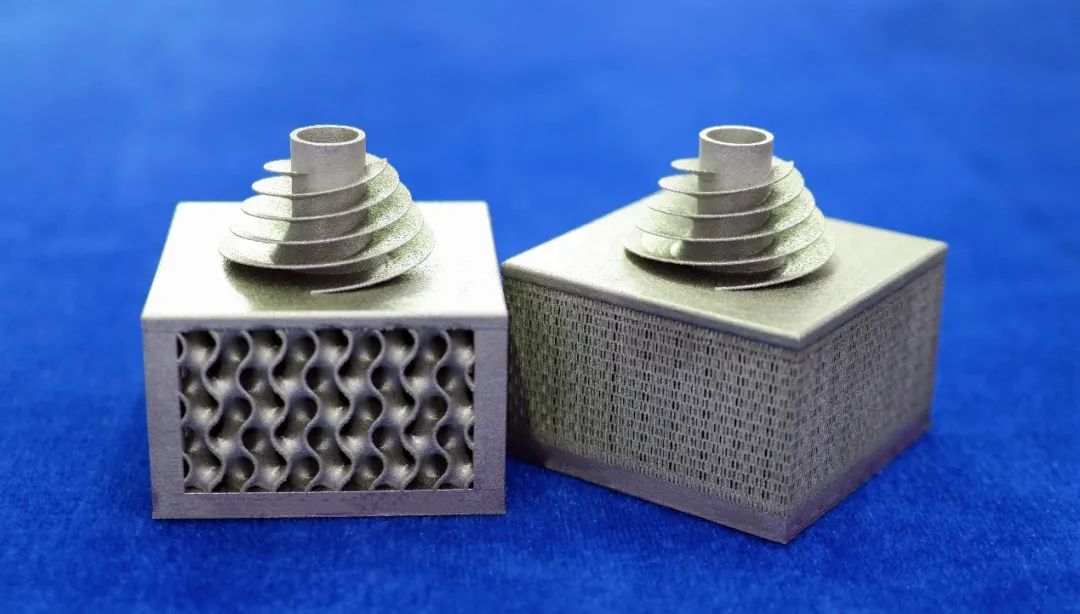

Metal parts printed without support by Zhongke Xianglong

In the LPBF (Laser Powder Bed Fusion) process, support structures are a key bottleneck limiting technological advancement. While they ensure printing stability, they also lead to increased material wastage, extended production cycles, and rising post-processing costs. Zhongke Xianglong, on a model of metal 3D printing equipment that does not include support-free printing technology, has broken through traditional technical limitations by deeply reconstructing the process system and precisely controlling laser energy. This has enabled support-free printing at low angles, even below 15°, while maintaining the surface quality and overall mechanical properties of the parts (equivalent to traditional supported processes). Furthermore, a synergistic optimization system has been constructed to "reduce costs, improve efficiency, and enhance quality."

From aerospace to consumer goods, comprehensive adaptation and value enhancement.

This means that Zhongke Xianglong's unsupported 3D printing integrated solution can also be adapted to various other types of metal 3D printers. Don't underestimate the "15°" figure; it represents a substantial technological leap.

It is reported that this technology is expected to demonstrate technological adaptability and application value across multiple fields.

In the aerospace field, it enables the integrated forming of complex components such as impellers and turbines. By reducing internal supports and expanding design freedom, it contributes to weight reduction and efficiency improvement of aircraft.

In the automotive manufacturing field, leveraging lightweight structural printing capabilities reduces material consumption for components, while simultaneously improving production rhythms and fuel economy.

In the field of medical devices, high precision and superior surface quality ensure product dimensional stability and safety.

In the consumer goods sector, design flexibility is used to meet personalized needs and enhance the company's market competitiveness.

△Turbine of a certain engine

Life Cycle Economic and Environmental Value

From the perspective of life cycle assessment, compared to traditional additive manufacturing methods, Zhongke Xianglong's support-free metal 3D printing technology offers significant advantages. By reducing or eliminating support structures, it greatly decreases powder consumption and minimizes material waste; it shortens printing time and reduces post-processing steps, effectively lowering energy consumption and improving the energy efficiency of the production process.

In addition, the optimized geometry helps parts dissipate heat more effectively and reduces stress concentrations, thereby extending the service life of the components. From a full life-cycle perspective, this enhances both the economic and environmental value of the technology.

Zhongke Xianglong's technology advances the LPBF technology from "feasible" to "efficient," "economical," and "sustainable" by overcoming process limitations, ensuring part quality, expanding application boundaries, and enhancing overall benefits, providing core support for the large-scale application of the additive manufacturing industry.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories