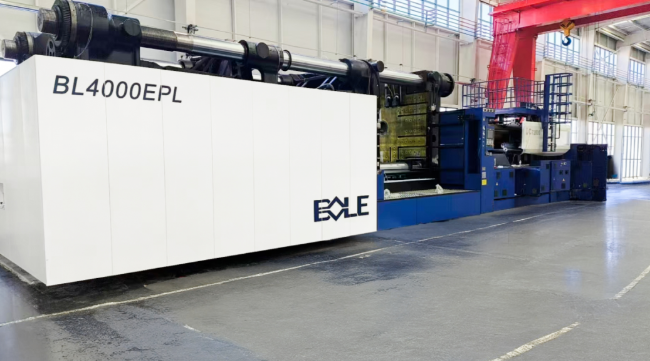

Bole 4000T Smart Injection Molding Machine Joins Dach, Ushering in New Era of Intelligent Manufacturing for Golf Cart Roofs

Recently, the Bole 4000T intelligent injection molding machine has officially entered the Dachi Intelligent Industrial Park. This landmark event promotes the deep integration of high-end equipment and intelligent manufacturing, leading the golf cart roof manufacturing industry to a new level.

Equipment Upgrades: Industrial Choices for Strong Alliances

Live Report

As a key enterprise in China's high-end component manufacturing sector, Dachi Intelligent's newly introduced Bole 4000T intelligent injection molding machine is a smart piece of equipment specifically designed for the integrated molding of golf cart roofs. The arrival of this "industrial behemoth" will provide core technological support for Dachi Intelligent in building a "smart factory," significantly enhancing its manufacturing capabilities and product competitiveness.

Technical Analysis: Redefining Manufacturing Standards

01Exceptional Performance

Boasting a 4000-ton clamping force, equipped with a fully closed-loop servo control system and a positioning accuracy of ±0.01mm, it can meet the integrated molding needs of large canopy components.

02Lightweight breakthrough

The device produces headliners that have successfully reduced product weight from 22 kg to 19 kg, a significant weight reduction that lays the foundation for improved energy efficiency and performance of the end product.

03Center Locking Structure

The central clamping structure of Bole Patents offers a large mold opening stroke and wide tie bar spacing, providing strong mold capacity and compatibility with large molds. The clamping force is evenly distributed, effectively reducing warping and distortion caused by uneven stress. It achieves 100% clamping force utilization, reduces internal stress in products, and enhances dimensional stability and durability.

04Intelligent Innovation

The AI parameter optimization system automatically adjusts the process parameters according to material properties; the unique modular pressure system ensures uniform force distribution on large workpieces; digital twin technology enables full lifecycle management of the equipment.

05Energy efficient

Compared with traditional equipment, the production cycle is shortened by more than 40%, and the innovative energy recovery system reduces energy consumption by 30%.

Industrial Revolution: Reshaping Ceiling Manufacturing Processes

The introduction of this super device will bring a fundamental transformation to Dachizhineng's ceiling manufacturing.

Process IntegrationIntegrating traditional multi-process splicing into a single-piece molding significantly enhances the structural strength, aesthetic integrity, and sealing performance of the ceiling.

Quality leap/Improvement in quality Elevating manufacturing precision to unprecedented industry levels, driving product quality to fully align with international high-end standards.

Customized production / Personalized production While maintaining economies of scale, it can better meet the market's growing demand for personalized and diversified customization, achieving "mass personalization manufacturing."

IV. Industry Outlook: The Future Landscape of Smart Manufacturing

This collaboration marks a dual innovation in production philosophy and manufacturing model. According to the head of Dach Chi Intelligent, the introduction of the Borche 4000T smart injection molding machine will provide support for building a flexible and intelligent production system, helping high-end golf cart components made in China compete globally.

Industry analysis suggests this case provides a referable path for intelligent transformation in the specialized component manufacturing industry. With the equipment put into production, the manufacturing of large plastic parts such as golf cart roofs is expected to achieve continuous breakthroughs in core processes and technologies, further solidifying the foundation for industrial upgrading.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

New 3D Printing Extrusion System Arrives, May Replace Traditional Extruders, Already Producing Car Bumpers