Bionic Polymer Interface Design: Unlocking the Potential of Comfort, Adhesion, and Biocompatibility in Skin-Integrated Devices

This article, authored by Shivani Srivastava, Head of Marketing and Communications at ChemBizR, explores the role of polymer interface materials in next-generation wearable devices and electronic skin systems.

The Forgotten Layer in Wearable Technology

In the wave of innovation surrounding wearable devices, biosensors, and electronic skin technology, the skin itself is often considered an afterthought. While the miniaturization of circuits and the improvement of sensor resolution have received most of the attention, the development of materials that physically connect these devices to the human body has been slower. Poor adhesion, discomfort, and inconsistent readings continue to affect performance, especially during prolonged wear or intense physical activity. Device disconnection, skin irritation, and user non-compliance are not merely usability issues; they pose data reliability issues and even commercial risks. In 2024 and 2025, there will be a noticeable shift from electronics-first to interface-first design. At the core of this shift is a set of bioinspired polymers designed not only for functionality but also for true compatibility with human skin.

Image source: Dragana Gordic/Shutterstock.com

Functional Requirements for Skin-Device Interface

The skin is a soft, elastic, moisture-rich, pH-variable, and constantly renewing surface. Its behavior is completely different from metals, glass, or plastics, which means that bonding electronic devices to the skin encounters a series of unique challenges. The interface must stretch and move with the skin, remain breathable, and maintain adhesion over time without causing trauma upon removal. It must also avoid triggering irritation or allergic reactions. A good skin-device interface should be able to hold sensors in place while maintaining comfort and providing clean signal data. This positions the material interface (not just the sensors) as the focal point of innovation.

Bionic adhesion mechanism

Design cues from biology have led to innovative adhesion strategies that are now applied or actively explored for wearable technology. Gecko-inspired dry adhesives, based on van der Waals interactions, produce micro-patterned silicone surfaces that can grip firmly yet release cleanly without residue. In 2025, researchers demonstrated a magnetic switchable gecko-patterned adhesive capable of reversible adhesion through controlled bending of surface microstructures. This provides new potential for re-wearable skin patches. In 2024, a PDMS film with mushroom-shaped micropillars emerged as a flexible, biocompatible interface suitable for skin-mounted sensors and stretchable electronic devices. Early studies also showed that gecko-inspired conductive silicone patches can maintain reliable electrocardiogram readings over multiple wear cycles, even under humid conditions.

Other nature-inspired approaches include suction-based adhesion modeled after octopus suckers, which are being developed for use in wet or moist environments. Although still primarily in the research stage, these designs hold promise for future wearable devices. Mucus-inspired hydrogels combine softness with controllable adhesiveness and have also attracted attention for temporary skin adhesion, especially in situations where moisture management is crucial. While many of these materials remain at the laboratory or prototype level, they are redefining how devices can connect to the human body comfortably and securely.

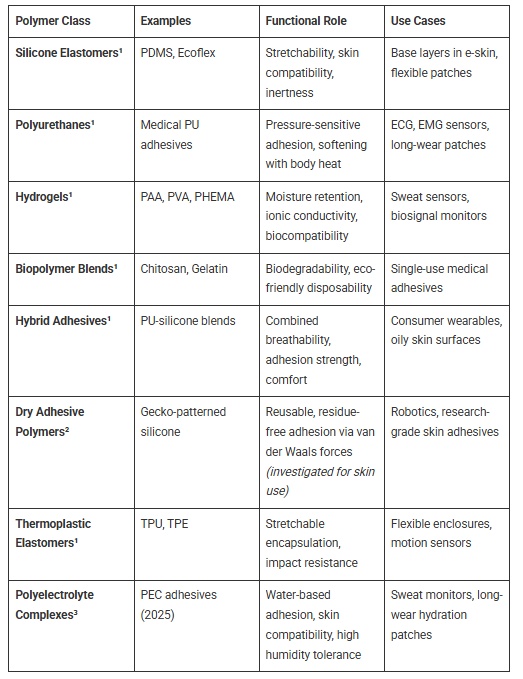

Advanced polymer categories used

Currently, various polymers are used to meet the demands of skin-integrated devices. Organic silicone elastomers such as PDMS and Ecoflex are widely used due to their stretchability and skin safety. Polyurethane adhesives are commonly employed in ECG and EMG patches because of their pressure-sensitive and thermoresponsive properties. Hydrogels like PAA, PVA, and PHEMA support ionic conductivity and moisture management, making them suitable for biosensors and sweat monitors. Biopolymer blends such as chitosan and gelatin appear in dissolvable or biodegradable forms for eco-friendly medical patches. These materials are often used in layered composite structures, where their mechanical, chemical, and biological properties need to be synergistically optimized.

Polymer categories for skin-integrated wearable devices

Commercial and research examples

Recent product releases indicate that skin-friendly polymer interfaces have become central to wearable device design. In 2023-2024, Epicore Biosystems launched the Gatorade Gx Sweat Patch, a disposable breathable biosensor for hydration tracking. The patch uses a skin-friendly adhesive and has received FDA registration for consumer use. In April 2024, Epicore Biosystems introduced the Connected Hydration Patch, a skin-integrated wearable device specifically designed for industrial and military applications. This patch is engineered to perform in high-sweat, high-stress environments, featuring a hypoallergenic adhesive that maintains a secure seal during prolonged activity. It continuously monitors sweat volume and electrolyte loss, issuing real-time hydration alerts through a connected mobile dashboard. In July 2025, Epicore was awarded a $1.2 million AFWERX Phase II contract to support hydration readiness in U.S. Air Force training environments. This also validates the patch’s role in mission-critical personnel performance monitoring.

In addition, at the end of 2023, DuPont launched the Liveo Soft Skin Adhesive Tape 1-3150. This silicone adhesive tape supports ECG and EEG applications, providing gentle, repositionable skin contact for multi-day wear. Another promising alternative will emerge in 2025 with the development of a water-based polyelectrolyte complex (PEC) adhesive specifically designed for wearable medical devices. This PEC adhesive matches the adhesive strength of commercial medical tapes like Tegaderm while significantly improving skin compatibility, especially under moist and sweaty conditions. Both examples reflect the growing emphasis on adhesives that combine safe, long-term contact with biocompatibility and comfort.

Recently, in mid-2025, researchers introduced a water-based polyelectrolyte complex (PEC) adhesive derived from industrial by-products. Specifically designed for wearable devices, it matches the adhesive performance of commercial medical tapes like Tegaderm, while significantly improving skin compatibility under humid and sweaty conditions. This adhesive uses a bio-based formulation, avoiding common irritants, and supports the comfort and sustainability goals of next-generation biosensor design.

Engineering Skin Interfaces: Materials and Manufacturing Trends

New manufacturing technologies are improving the functionality of these materials in wearable formats. Micropores and solvent casting are now used to manufacture breathable films. Additionally, materials with gradient stiffness are used to gradually transfer mechanical stress from rigid devices to soft skin. Printed hydrogel patterns can apply adhesive force only where needed. This increases comfort. Stretchable thermoplastic sealants are designed to deform with the skin and maintain stable signals during movement. These developments are not ornamental; they directly impact data quality, device safety, and user adoption rates.

Challenges of Long-term Biological Integration

There is no doubt that progress has been made, but obstacles still exist. Prolonged use of adhesive materials can cause skin damage, especially in sensitive or elderly populations. Sweat and skin oils can accumulate under devices and interfere with adhesion or sensor function. Uneven skin pressure can lead to signal noise or loss. Most importantly, all skin-contact materials must pass ISO 10993 testing for irritation, sensitization, and cytotoxicity, which adds to development costs and complexity. Companies are actively addressing these issues, but they remain key obstacles to true long-term skin integration.

Outlook: Towards the Next-Generation Polymer-Epidermis Interface

In the coming years, new materials will focus on performance, sustainability, and user control. Researchers are exploring the use of post-decomposed biodegradable adhesives to reduce medical and consumer waste. Smart adhesives that release on command triggered by heat, light, or chemicals are in the early stages of development. Breathable films that can regulate temperature and humidity are also being sought. As these technologies mature, device manufacturers will need to rethink their entire design approach. Skin is not a passive surface; it is an active, dynamic environment. Materials capable of adapting to it will define the next wave of innovation in healthcare, sports, and consumer electronics.

【Copyright and Disclaimer】This article is the property of PlastMatch. For business cooperation, media interviews, article reprints, or suggestions, please call the PlastMatch customer service hotline at +86-18030158354 or via email at service@zhuansushijie.com. The information and data provided by PlastMatch are for reference only and do not constitute direct advice for client decision-making. Any decisions made by clients based on such information and data, and all resulting direct or indirect losses and legal consequences, shall be borne by the clients themselves and are unrelated to PlastMatch. Unauthorized reprinting is strictly prohibited.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track