Biodegradable and bioabsorbable glass fibers, compostable composite components

Bioabsorbable bone fixation implants made by ABM Composite (upper left) and an automotive brake pedal (right) made from the ArcBiox BGF30-B1 long fiber technology (LFT) compound, which is PLA reinforced with degradable glass fibers, ArcBiox X4. The ArcBiox BGF30-B1 has passed industrial composting tests according to EN 13432 standards by German DIN CERTCO/TUV (Image source: ABM Composite)

What if, in addition to offering decades-proven benefits such as weight reduction, strength and stiffness, corrosion resistance, and durability, glass fiber-reinforced polymer (GFRP) composites could also be composted at the end of their service life? This is the appeal brought by the technology of ABM Composite.

Bioactive Glass, High-Strength Fibers

Founded in 2014, Arctic Biomaterials Oy (Tampere, Finland) has developed a biodegradable glass fiber made from so-called bioactive glass. According to Ari Rosling, R&D Director of ABM Composite, "This is a special formula developed in the 1960s that allows the glass to degrade under physiological conditions. When entering the human body, the glass breaks down into its component mineral salts, releasing sodium, magnesium, phosphates, etc., thereby creating conditions that stimulate bone growth."

Bioabsorbable bone fixation implants made by ABM Composite (upper left) and an automotive brake pedal (right) made from the ArcBiox BGF30-B1 long fiber technology (LFT) compound, which is a polylactic acid (PLA) reinforced with ArcBiox X4 degradable glass fibers. The ArcBiox BGF30-B1 has passed industrial composting tests conducted by German DIN CERTCO/TUV according to EN 13432 standards (Image source: ABM Composite)

What if glass fiber-reinforced polymer (GFRP) composites, in addition to providing decades-proven advantages such as weight reduction, strength and stiffness, corrosion resistance, and durability, could also be composted at the end of their service life? This is exactly the appeal of the technology offered by ABM Composite.

Bioactive Glass, High-Strength Fibers

Established in 2014, Arctic Biomaterials Oy (Tampere, Finland) developed a degradable glass fiber made from so-called bioactive glass. According to Ari Rosling, R&D Director at ABM Composite, "This is a special formula developed in the 1960s that allows the glass to degrade under physiological conditions. When it enters the human body, the glass breaks down into its constituent mineral salts, releasing sodium, magnesium, phosphates, etc., thereby creating conditions that stimulate bone growth."

Bioabsorbable bone fixation implants made by ABM Composite (upper left) and an automotive brake pedal (right) made from ArcBiox BGF30-B1 long fiber technology (LFT) compound, which is PLA reinforced with ArcBiox X4 degradable glass fibers. ArcBiox BGF30-B1 has passed industrial composting tests according to EN 13432 standards by German DIN CERTCO/TUV (Image source: ABM Composite)

What if, in addition to the well-proven benefits of weight reduction, strength and stiffness, corrosion resistance, and durability that have been provided for decades, glass fiber-reinforced polymer (GFRP) composites could also be composted at the end of their service life? This is exactly the appeal of the technology offered by ABM Composite.

Bioactive Glass, High-Strength Fibers

Founded in 2014, Arctic Biomaterials Oy (Tampere, Finland) has developed a degradable glass fiber made from so-called bioactive glass. According to Ari Rosling, R&D Director of ABM Composite, "This is a special formula developed in the 1960s that allows the glass to degrade under physiological conditions. When it enters the human body, the glass breaks down into its constituent mineral salts, releasing sodium, magnesium, phosphates, etc., thereby creating conditions that stimulate bone growth."

Bioabsorbable bone fixation implants made by ABM Composite (upper left) and an automotive brake pedal (right) made from the ArcBiox BGF30-B1 long fiber technology (LFT) compound, which is a blend of polylactic acid (PLA) reinforced with ArcBiox X4 degradable glass fibers. The ArcBiox BGF30-B1 has passed industrial composting tests conducted by German DIN CERTCO/TUV according to EN 13432 standards (Image source: ABM Composite)

What if, in addition to the proven advantages of weight reduction, strength and stiffness, corrosion resistance, and durability that fiberglass-reinforced polymer (GFRP) composites have offered for decades, they could also be composted at the end of their life? This is precisely the appeal of the technology brought by ABM Composite.

Bioactive glass, high-strength fibers

Founded in 2014, Arctic Biomaterials Oy (Tampere, Finland) has developed a biodegradable glass fiber made from so-called bioactive glass. According to Ari Rosling, R&D Director of ABM Composite, "This is a special formula developed in the 1960s that allows the glass to degrade under physiological conditions. When it enters the human body, the glass breaks down into its constituent mineral salts, releasing sodium, magnesium, phosphates, etc., thereby creating conditions that stimulate bone growth."

Bioabsorbable bone fixation implants made by ABM Composite (upper left) and an automotive brake pedal (right) made from the ArcBiox BGF30-B1 long fiber technology (LFT) compound, which is polylactic acid (PLA) reinforced with ArcBiox X4 degradable glass fibers. ArcBiox BGF30-B1 has passed industrial composting tests according to EN 13432 standards by German DIN CERTCO/TUV (Image source: ABM Composite)

What if, in addition to providing decades-proven benefits such as weight reduction, strength and stiffness, corrosion resistance, and durability, fiberglass-reinforced polymer (GFRP) composites could also be composted at the end of their service life? This is exactly the appeal of the technology brought by ABM Composite.

Bioactive Glass, High-Strength Fibers

Founded in 2014, Arctic Biomaterials Oy (Tampere, Finland) developed a degradable glass fiber made from so-called bioactive glass. According to Ari Rosling, R&D Director of ABM Composite, "This is a special formula developed in the 1960s that allows the glass to degrade under physiological conditions. When it enters the body, the glass breaks down into its constituent mineral salts, releasing sodium, magnesium, phosphates, etc., thus creating conditions that stimulate bone growth."

Bioabsorbable bone fixation implants made by ABM Composite (upper left) and an automotive brake pedal (right) made from the ArcBiox BGF30-B1 long fiber technology (LFT) compound, which is polylactic acid (PLA) reinforced with degradable glass fibers, ArcBiox X4. The ArcBiox BGF30-B1 has passed industrial composting tests according to EN 13432 standards by German DIN CERTCO/TUV (Image source: ABM Composite)

What if, in addition to providing decades-proven benefits such as weight reduction, strength and stiffness, corrosion resistance, and durability, fiberglass-reinforced polymer (GFRP) composites could also be composted at the end of their life? This is exactly the appeal of the technology brought by ABM Composite.

Bioactive Glass, High-Strength Fibers

Founded in 2014, Arctic Biomaterials Oy (Tampere, Finland) has developed a degradable glass fiber made from so-called bioactive glass. According to Ari Rosling, R&D Director of ABM Composite, "This is a special formula developed in the 1960s that allows the glass to degrade under physiological conditions. When it enters the human body, the glass breaks down into its component mineral salts, releasing sodium, magnesium, phosphates, etc., thus creating conditions that stimulate bone growth."

Typical species

Bioabsorbable bone fixation implants made by ABM Composite (upper left) and an automotive brake pedal (right) made from the ArcBiox BGF30-B1 long fiber technology (LFT) compound, which is polylactic acid (PLA) reinforced with ArcBiox X4 degradable glass fibers. ArcBiox BGF30-B1 has passed industrial composting tests according to EN 13432 standards conducted by German DIN CERTCO/TUV (Image source: ABM Composite)

What if, in addition to providing decades-proven advantages such as weight reduction, strength and stiffness, corrosion resistance, and durability, glass fiber-reinforced polymer (GFRP) composites could also be composted at the end of their service life? This is precisely the appeal of the technology offered by ABM Composite.

Bioactive Glass, High-Strength Fibers

Founded in 2014, Arctic Biomaterials Oy (Tampere, Finland) has developed a degradable glass fiber made from so-called bioactive glass. According to Ari Rosling, R&D Director of ABM Composite, "This is a special formula developed in the 1960s that allows the glass to degrade under physiological conditions. When it enters the human body, the glass breaks down into its constituent mineral salts, releasing sodium, magnesium, phosphates, etc., thus creating conditions that stimulate bone growth."

Typical properties (Image source: ABM

Bioabsorbable bone fixation implants manufactured by ABM Composite (upper left) and an automobile brake pedal (right) made from a compound using ArcBiox BGF30-B1 long fiber technology (LFT), which is polylactic acid (PLA) reinforced with degradable glass fibers of ArcBiox X4. ArcBiox BGF30-B1 has passed the industrial composting test according to EN 13432 standards conducted by DIN CERTCO/TUV in Germany (Image source: ABM Composite)

Bioabsorbable bone fixation implants manufactured by ABM Composite (upper left) and an automobile brake pedal (right) made from a compound using ArcBiox BGF30-B1 long fiber technology (LFT), which is polylactic acid (PLA) reinforced with degradable glass fibers of ArcBiox X4. ArcBiox BGF30-B1 has passed the industrial composting test according to EN 13432 standards conducted by DIN CERTCO/TUV in Germany (Image source: ABM Composite)

Bone fixation implants made by ABM Composite (upper left) and an automotive brake pedal (right) made from the ArcBiox BGF30-B1 long fiber technology (LFT) compound, which is PLA reinforced with ArcBiox X4 degradable glass fibers. ArcBiox BGF30-B1 has passed industrial composting tests according to EN 13432 standards by German DIN CERTCO/TUV (Image source: ABM Composite)

What if fiberglass-reinforced polymer (GFRP) composites, in addition to offering proven weight reduction, strength and stiffness, corrosion resistance, and durability over decades, could also be composted at the end of their life? This is the appeal of the technology from ABM Composite.

What if fiberglass-reinforced polymer (GFRP) composites, in addition to offering proven weight reduction, strength and stiffness, corrosion resistance, and durability over decades, could also be composted at the end of their life? This is the appeal of the technology from ABM Composite.

What if fiberglass-reinforced polymer (GFRP) composites, in addition to offering proven weight reduction, strength and stiffness, corrosion resistance, and durability over decades, could also be composted at the end of their life? This is the appeal of the technology from ABM Composite.Bioactive glass, high-strength fibers

Bioactive glass, high-strength fibers

Bioactive glass, high-strength fibers

Bioactive glass, high-strength fibersFounded in 2014, Arctic Biomaterials Oy (Tampere, Finland) developed a degradable glass fiber made from so-called bioactive glass. According to Ari Rosling, R&D Director of ABM Composite, "This is a special formula developed in the 1960s that allows the glass to degrade under physiological conditions. When it enters the human body, the glass breaks down into its constituent mineral salts, releasing sodium, magnesium, phosphates, etc., thereby creating conditions that stimulate bone growth."

Founded in 2014, Arctic Biomaterials Oy (Tampere, Finland) developed a degradable glass fiber made from so-called bioactive glass. According to Ari Rosling, R&D Director of ABM Composite, "This is a special formula developed in the 1960s that allows the glass to degrade under physiological conditions. When it enters the human body, the glass breaks down into its constituent mineral salts, releasing sodium, magnesium, phosphates, etc., thereby creating conditions that stimulate bone growth."

Founded in 2014, Arctic Biomaterials Oy (Tampere, Finland) has developed a degradable glass fiber made from so-called bioactive glass. According to Ari Rosling, the R&D Director of ABM Composite, "This is a special formula developed in the 1960s that allows the glass to degrade under physiological conditions. When it enters the human body, the glass breaks down into its constituent mineral salts, releasing sodium, magnesium, phosphates, and so on, thereby creating conditions that stimulate bone growth."Typical properties (Image source: ABM Composite)

Typical properties (Image source: ABM Composite)

Typical properties (Image source: ABM Composite)

"Its properties are similar to those of alkali-free glass (E-glass)," said Rosling. "But this bioactive glass is difficult to manufacture and draw into fibers; previously, it was only used as a powder or putty. To our knowledge, ABM Composite is the first company to produce high-strength glass fibers from it on an industrial scale, and now we use these ArcBiox X4/5 glass fibers to reinforce various types of plastics, including biodegradable polymers."

"Its properties are similar to those of alkali-free glass (E-glass)," said Rosling. "But this bioactive glass is difficult to manufacture and draw into fibers; previously, it was only used as a powder or putty. To our knowledge, ABM Composite is the first company to produce high-strength glass fibers from it on an industrial scale, and now we use these ArcBiox X4/5 glass fibers to reinforce various types of plastics, including biodegradable polymers."

"Its properties are similar to those of alkali-free glass (E-glass)," said Rosling. "But this bioactive glass is difficult to manufacture and draw into fibers; previously, it was only used as a powder or putty. To our knowledge, ABM Composite is the first company to produce high-strength glass fibers from it on an industrial scale, and now we use these ArcBiox X4/5 glass fibers to reinforce various types of plastics, including biodegradable polymers."Medical Implants

Medical Implants

Medical ImplantsThe Tampere region, located about a two-hour drive north of Helsinki, Finland, has been a center for biobased, biodegradable polymers for medical applications since the 1980s. "One of the first commercial implants made with these materials was produced in Tampere, and that's how ABM Composite got its start, which is now our medical business unit," explained Rosling.

The Tampere region, located a 2-hour drive north of Helsinki, Finland, has been a center for bio-based biodegradable polymers for medical applications since the 1980s. Rosling introduced: "One of the first commercial implants made from these materials was produced in Tampere, and that's how ABM Composite got its start; it is now our medical business unit."

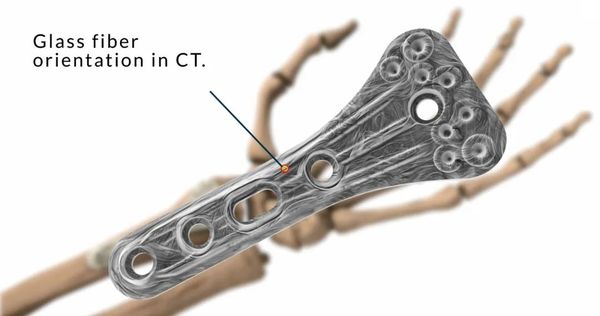

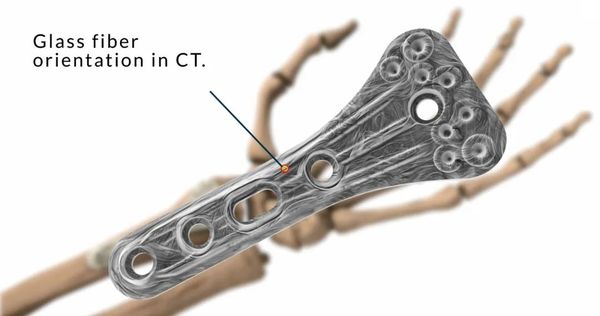

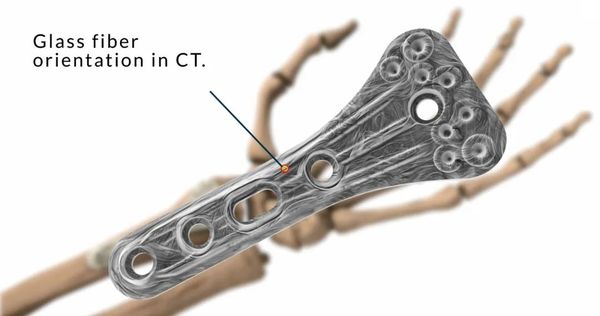

Image source: ABM Composite

Image source: ABM Composite

Image source: ABM Composite

Therefore, compared to implants made from unreinforced polymers, ABM Composite's implants offer higher performance while also being bioabsorbable and promoting bone formation and growth. ABM Composite also uses automated fiber/yarn placement technology to ensure optimal fiber orientation, including laying fibers along the entire length of the implant and placing additional fibers at potential weak points.

Therefore, compared to implants made from unreinforced polymers, ABM Composite's implants offer higher performance while also being bioabsorbable and promoting bone formation and growth. ABM Composite also uses automated fiber/yarn placement technology to ensure optimal fiber orientation, including laying fibers along the entire length of the implant and placing additional fibers at potential weak points.

Therefore, compared to implants made from unreinforced polymers, ABM Composite's implants offer higher performance while also being bioabsorbable and promoting bone formation and growth. ABM Composite also uses automated fiber/yarn placement technology to ensure optimal fiber orientation, including laying fibers along the entire length of the implant and placing additional fibers at potential weak points.Household and technical applications

Household and technical applications

Household and technical applications

Household and technical applicationsAs the medical business unit continues to grow, ABM Composite recognizes that bio-based and biodegradable polymers can also be used for kitchen utensils, tableware, and other household items. "In this regard, compared to oil-based plastics, these biodegradable polymers typically have poorer mechanical properties," Rosling said. "But we can reinforce these materials with our degradable glass fibers, making them a good alternative to fossil-based commercial plastics for a wide range of technical applications."

As the medical business unit continues to grow, ABM Composite recognizes that bio-based and biodegradable polymers can also be used for kitchen utensils, tableware, and other household items. "In this regard, compared to oil-based plastics, these biodegradable polymers typically have poorer mechanical properties," Rosling said. "But we can reinforce these materials with our degradable glass fibers, making them a good alternative to fossil-based commercial plastics for a wide range of technical applications."

As the medical business unit continues to grow, ABM Composite recognizes that bio-based and biodegradable polymers can also be used for kitchen utensils, tableware, and other household items. "In this regard, compared to oil-based plastics, these biodegradable polymers typically have poorer mechanical properties," Rosling said. "But we can reinforce these materials with our degradable glass fibers, making them a good alternative to fossil-based commercial plastics for a wide range of technical applications."

Image source: ABM Composite

Image source: ABM Composite

Image source: ABM Composite

Therefore, ABM Composite has expanded its technical business unit, which now employs 60 people. "We offer a more sustainable end-of-life (EOL) solution," Rosling stated, "Our value proposition is to place these biodegradable composites into industrial composting operations where they turn into soil." Traditional E-glass is inert and does not degrade in these composting facilities.

Therefore, ABM Composite has expanded its technical business unit, which now employs 60 people. "We offer a more sustainable end-of-life (EOL) solution," Rosling stated, "Our value proposition is to place these biodegradable composites into industrial composting operations where they turn into soil." Traditional E-glass is inert and does not degrade in these composting facilities.

Therefore, ABM Composite has expanded its technical business unit, which now employs 60 people. "We offer a more sustainable end-of-life (EOL) solution," Rosling stated, "Our value proposition is to place these biodegradable composites into industrial composting operations where they turn into soil." Traditional E-glass is inert and does not degrade in these composting facilities.ArcBiox Fiber Composite Material

ArcBiox Fiber Composite Material

ArcBiox Fiber Composite MaterialABM Composite has developed various forms of ArcBiox X4/5 glass fibers for composite applications, ranging from chopped fibers and injection molding compounds to continuous fibers for processes such as textiles and pultrusion. Its ArcBiox BSGF series combines degradable glass fibers with bio-based polyester resins, offering both general-purpose technical grades and ArcBiox 5 grade, which is approved for food contact products.

ABM Composite has developed various forms of ArcBiox X4/5 glass fibers for composite applications, ranging from chopped fibers and injection molding compounds to continuous fibers for processes such as textiles and pultrusion. Its ArcBiox BSGF series combines degradable glass fibers with bio-based polyester resins, offering both general-purpose technical grades and ArcBiox 5 grade, which is approved for food contact products.

ABM Composite has developed various forms of ArcBiox X4/5 glass fibers for composite applications, ranging from chopped fibers and injection molding compounds to continuous fibers for processes such as textiles and pultrusion. Its ArcBiox BSGF series combines degradable glass fibers with bio-based polyester resins, offering both general-purpose technical grades and ArcBiox 5 grade, which is approved for food contact products.

ArcBiox X4/5 fiberglass is available in both chopped and continuous forms, with the latter suitable for processes such as weaving and pultrusion, as shown in the bottom right combined with a bio-based polyester resin (Image source: ABM Composite)

ArcBiox X4/5 fiberglass is available in both chopped and continuous forms, with the latter suitable for processes such as weaving and pultrusion, as shown in the bottom right combined with a bio-based polyester resin (Image source: ABM Composite)

ArcBiox X4/5 fiberglass is available in both chopped and continuous forms, with the latter suitable for processes such as weaving and pultrusion, as shown in the bottom right combined with a bio-based polyester resin (Image source: ABM Composite)

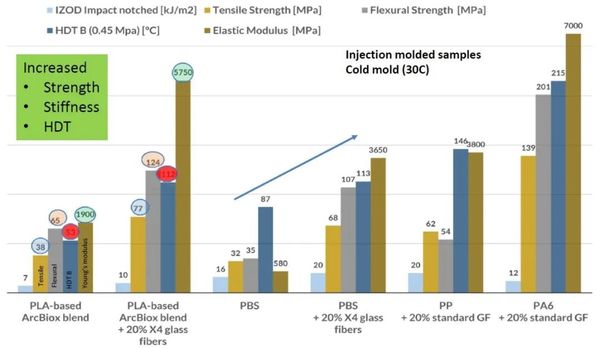

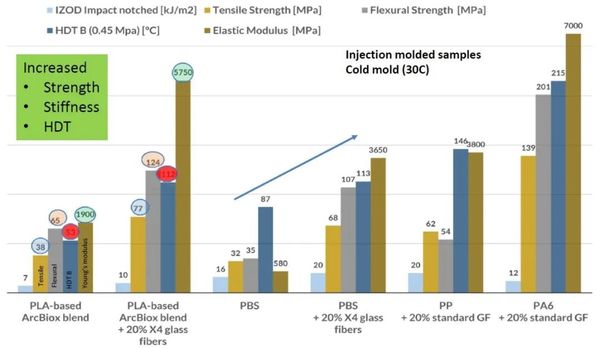

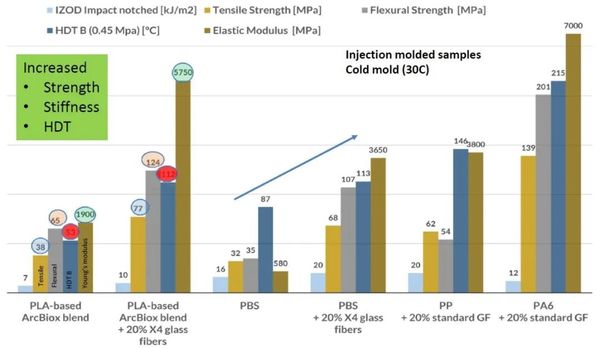

ABM Composite has also researched various biodegradable and bio-based polymers, including polylactic acid (PLA), PLLA, and polybutylene succinate (PBS). The following figure shows how X4/5 fiberglass enhances performance to compete with standard glass fiber-reinforced polymers such as polypropylene (PP) and even polyamide 6 (PA6).

ABM Composite has also researched various biodegradable and bio-based polymers, including polylactic acid (PLA), PLLA, and polybutylene succinate (PBS). The following figure shows how X4/5 fiberglass enhances performance to compete with standard glass fiber-reinforced polymers such as polypropylene (PP) and even polyamide 6 (PA6).

ABM Composite has also researched various biodegradable and bio-based polymers, including polylactic acid (PLA), PLLA, and polybutylene succinate (PBS). The following figure shows how X4/5 fiberglass enhances performance to compete with standard glass fiber-reinforced polymers such as polypropylene (PP) and even polyamide 6 (PA6).

Image source: ABM Composite

Image source: ABM Composite

Image source: ABM Composite

Rosling stated that bio-based PP and PA (whose production is rapidly increasing) do not degrade. "While bio-based PLA and PBS do degrade, their mechanical properties and heat resistance are typically very low. Our degradable glass fiber represents a significant step forward, greatly improving its performance to enable new applications."

Rosling stated that bio-based PP and PA (whose production is rapidly increasing) do not degrade. "While bio-based PLA and PBS do degrade, their mechanical properties and heat resistance are typically very low. Our degradable glass fiber represents a significant step forward, greatly improving its performance to enable new applications."

Rosling stated that bio-based PP and PA (whose production is rapidly increasing) do not degrade. "While bio-based PLA and PBS do degrade, their mechanical properties and heat resistance are typically very low. Our degradable glass fiber represents a significant step forward, greatly improving its performance to enable new applications."```htmlDurability and Compostability

Durability and Compostability

Durability and Compostability

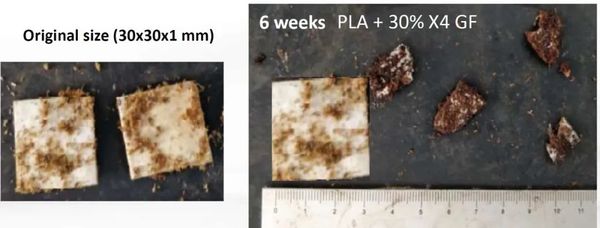

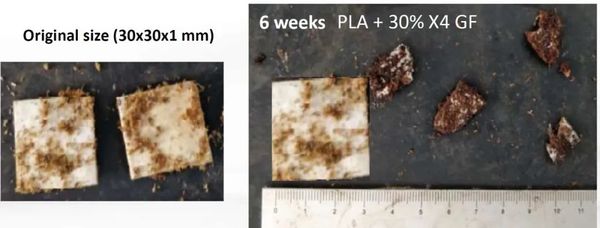

Durability and CompostabilityIf these composites are biodegradable, how can they be durable? "Our X4/5 glass fibers do not dissolve like sugar in 5 minutes or overnight. Although their performance will decrease over time, it is not so noticeable," Rosling said. "For effective degradation, we need prolonged elevated temperatures and humidity, similar to what is found in the body or industrial compost piles. For example, we tested cups and bowls made with our ArcBiox BSGF material, which can withstand up to 200 dishwashing cycles without losing functionality. While mechanical properties do decrease to some extent, they do not drop to a level where the cup is no longer safe to use."

If these composites are biodegradable, how can they be durable? "Our X4/5 glass fibers do not dissolve like sugar in 5 minutes or overnight. Although their performance will decrease over time, it is not so noticeable," Rosling said. "For effective degradation, we need prolonged elevated temperatures and humidity, similar to what is found in the body or industrial compost piles. For example, we tested cups and bowls made with our ArcBiox BSGF material, which can withstand up to 200 dishwashing cycles without losing functionality. While mechanical properties do decrease to some extent, they do not drop to a level where the cup is no longer safe to use."

```If these composite materials are biodegradable, how can they be durable? "Our X4/5 fiberglass does not dissolve in 5 minutes or overnight like sugar. Although its performance will decrease over time, it won't be so noticeable," Rosling said. "For effective degradation, we need prolonged elevated temperatures and humidity, similar to what is found inside the body or in industrial compost piles. For example, we tested cups and bowls made with our ArcBiox BSGF material, which can withstand up to 200 dishwasher cycles without losing functionality. While mechanical properties do decrease to some extent, they don't degrade to a point where the cup can no longer be used safely."

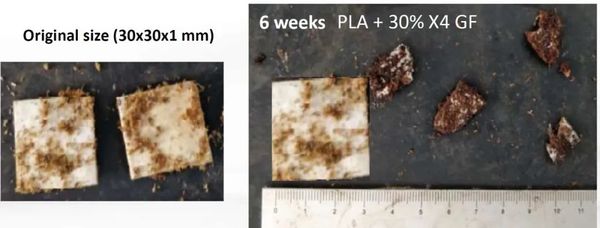

During industrial composting tests, the ArcBiox material using X4 glass fiber met the standard requirements of breaking down into <2 mm fragments and biodegrading 90% (measured by carbon content) within 90 days. * Cold mold injection molding, ** crystalline material hot injection molding. 1. Compliant with UNI EN ISO 20200:2016 standard, MP 2238 rev 0 2017 standard, 2. Oxygen biodegradation performance test conducted according to ISO 14855-1:2012 (Image source: ABM Composite)

During industrial composting tests, the ArcBiox material using X4 glass fiber met the standard requirements of breaking down into <2 mm fragments and biodegrading 90% (measured by carbon content) within 90 days. * Cold mold injection molding, ** crystalline material hot injection molding. 1. Compliant with UNI EN ISO 20200:2016 standard, MP 2238 rev 0 2017 standard, 2. Oxygen biodegradation performance test conducted according to ISO 14855-1:2012 (Image source: ABM Composite)

During industrial composting tests, the ArcBiox material using X4 glass fiber met the standard requirements of breaking down into <2 mm fragments and biodegrading 90% (measured by carbon content) within 90 days. * Cold mold injection molding, ** crystalline material hot injection molding. 1. Compliant with UNI EN ISO 20200:2016 standard, MP 2238 rev 0 2017 standard, 2. Oxygen biodegradation performance test conducted according to ISO 14855-1:2012 (Image source: ABM Composite)

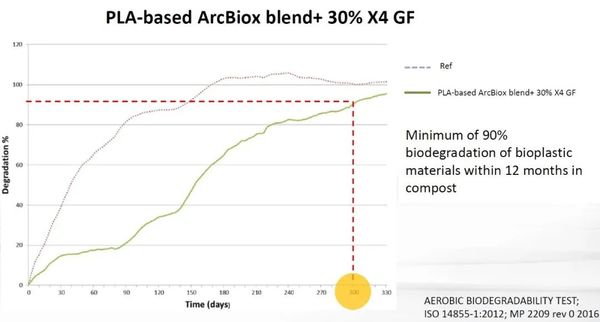

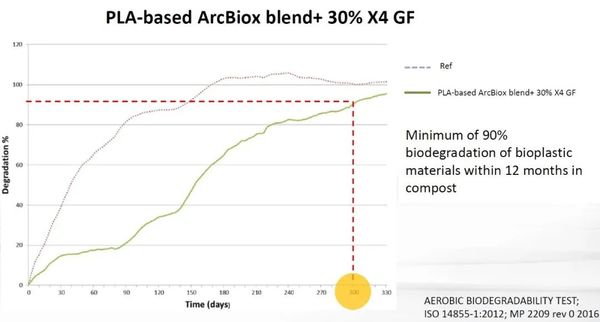

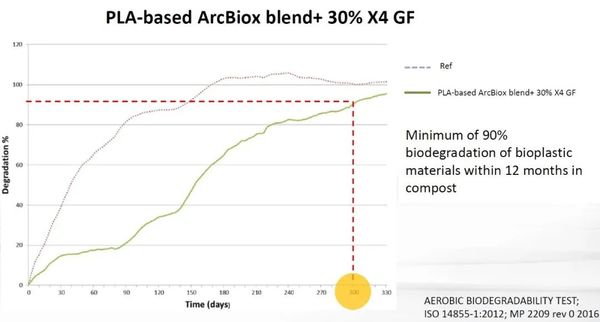

Therefore, ABM Composite has demonstrated that its materials can be certified as compostable according to EN 13432 standards. So far, the tests its materials have passed include: the test for the final aerobic biodegradation capability of materials under controlled composting conditions (biodegradation) ISO 14855-1, the aerobic controlled disintegration test ISO 16929, the chemical requirement test ISO DIN EN 13432, and the plant test (ecotoxicity test) OECD 208, ISO DIN EN 13432.

Therefore, ABM Composite has demonstrated that its materials can be certified as compostable according to EN 13432 standards. So far, the tests its materials have passed include: the test for the final aerobic biodegradability of materials under controlled composting conditions (biodegradation) ISO 14855-1, the aerobic controlled disintegration test ISO 16929, chemical requirement testing ISO DIN EN 13432, plant trials (ecotoxicity tests) OECD 208, ISO DIN EN 13432.

Therefore, ABM Composite has demonstrated that its materials can be certified as compostable according to EN 13432 standards. So far, the tests its materials have passed include: the test for the final aerobic biodegradability of materials under controlled composting conditions (biodegradation) ISO 14855-1, the aerobic controlled disintegration test ISO 16929, chemical requirement testing ISO DIN EN 13432, plant trials (ecotoxicity tests) OECD 208, ISO DIN EN 13432.```htmlCO2 released during the composting process

CO2 released during the composting process

CO2 released during the composting process

CO2 released during the composting processDuring the composting process, CO2 is indeed released, but some of it remains in the soil and is then utilized by plants. Research on composting has been ongoing for decades, and whether through industrial processes or backyard methods, the amount of CO2 released is less compared to other waste management alternatives. Composting is still considered an environmentally friendly and carbon footprint-reducing process.

During the composting process, CO2 is indeed released, but some of it remains in the soil and is then utilized by plants. Research on composting has been ongoing for decades, and whether through industrial processes or backyard methods, the amount of CO2 released is less compared to other waste management alternatives. Composting is still considered an environmentally friendly and carbon footprint-reducing process.

During the composting process, CO2 is indeed released, but some of it remains in the soil and is then utilized by plants. Research on composting has been ongoing for decades, and whether through industrial processes or backyard methods, the amount of CO2 released is less compared to other waste management alternatives. Composting is still considered an environmentally friendly and carbon footprint-reducing process.

ABM Composite has also demonstrated that the plants grown in its compostable materials are non-toxic (above) and have met the requirements for aerobic biodegradation under home composting conditions (below) (Image source: ABM Composite)

ABM Composite has also demonstrated that the plants grown in its compostable materials are non-toxic (above) and have met the requirements for aerobic biodegradation under home composting conditions (below) (Image source: ABM Composite)

ABM Composite has also demonstrated that the plants grown in its compostable materials are non-toxic (above) and have met the requirements for aerobic biodegradation under home composting conditions (below) (Image source: ABM Composite)

Ecotoxicity requires testing of the biomass formed during the composting process and the plants grown using this biomass. "This is to ensure that the compost from these products does not harm growing plants," said Rosling. Additionally, ABM Composite has proven that its materials meet the biodegradability requirements under home composting conditions, which also require 90% biodegradability, but over a period of 12 months, as opposed to the shorter timeframe for industrial composting operations.

Ecotoxicity requires testing of the biomass formed during the composting process and the plants grown using this biomass. "This is to ensure that the compost from these products does not harm growing plants," said Rosling. Additionally, ABM Composite has proven that its materials meet the biodegradability requirements under home composting conditions, which also require 90% biodegradability, but over a period of 12 months, as opposed to the shorter timeframe for industrial composting operations.

Ecotoxicity requires testing of the biomass formed during the composting process and the plants grown using this biomass. "This is to ensure that the compost from these products does not harm growing plants," said Rosling. Additionally, ABM Composite has proven that its materials meet the biodegradability requirements under home composting conditions, which also require 90% biodegradability, but over a period of 12 months, as opposed to the shorter timeframe for industrial composting operations.Industrial applications, production, costs, and future growth

Industrial applications, production, costs, and future growth

Industrial applications, production, costs, and future growth

Industrial applications, production, costs, and future growthCurrently, X4/5 glass fibers are more expensive than E-glass fibers, but the production volume is also relatively small. ABM Composite is seeking multiple opportunities to expand applications and to scale up production to 20,000 tons per year as demand grows, which will also help reduce costs. Nevertheless, Rosling stated that in many cases, the cost of meeting sustainability and new regulatory requirements has not been fully considered. At the same time, the urgency to save the planet is increasing. "Society is already pushing for more bio-based products to come to market," he explained. "There are now many incentives to push circular technologies forward, and the world needs to move faster in this area. I believe that in the future, society will only increase its efforts to promote bio-based products."

Currently, X4/5 glass fibers are more expensive than E-glass fibers, but the production volume is also relatively small. ABM Composite is seeking multiple opportunities to expand the application scope and facilitate increasing production to 20,000 tons per year as demand grows, which will also help reduce costs. Nevertheless, Rosling noted that in many cases, the costs associated with meeting sustainability and new regulatory requirements have not been fully considered. Meanwhile, the urgency to save the planet is increasing. "Society is already pushing for more bio-based products to hit the market," he explained, "There are now many incentives to advance circular technologies, and the world needs to move faster in this area. I believe that in the future, society will only intensify its push for bio-based products."

Currently, X4/5 fiberglass is more expensive than E-glass, but the production volume is also relatively smaller. ABM Composite is seeking various opportunities to expand its application scope and to facilitate an increase in production to 20,000 tons per year as demand grows, which would also help reduce costs. Nevertheless, Rosling notes that in many cases, the costs associated with meeting sustainability and new regulatory requirements have not been fully considered. Meanwhile, the urgency to save the Earth is increasing. "Society is already pushing for more bio-based products," he explains. "There are now many incentives driving circular technologies forward, and the world needs to move faster in this area. I believe that in the future, society will only intensify its push for bio-based products."LCA and Sustainability Advantages

LCA and Sustainability Advantages

LCA and Sustainability Advantages

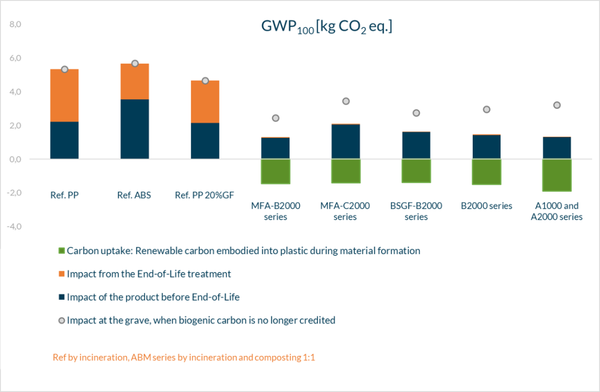

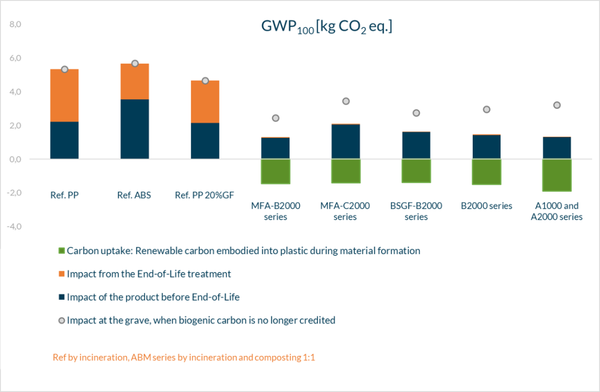

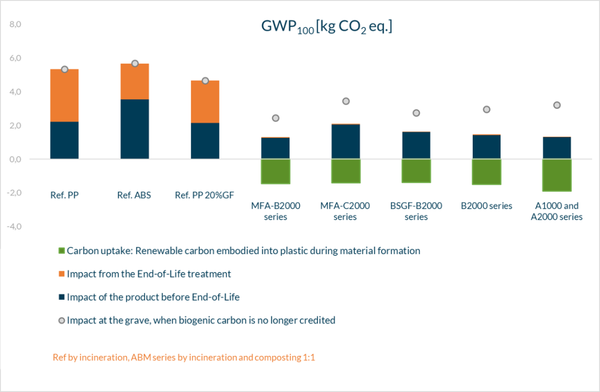

LCA and Sustainability AdvantagesRosling states that ABM Composite's materials can reduce greenhouse gas emissions and the use of non-renewable energy by 50%-60% per kilogram. "We are using the Environmental Footprint Database 2.0, accredited GaBi datasets, and methods outlined in ISO 14040 and ISO 14044 to conduct LCA (Life Cycle Assessment) calculations for our products."

Rosling states that ABM Composite's materials can reduce greenhouse gas emissions and the use of non-renewable energy by 50%-60% per kilogram. "We are using the Environmental Footprint Database 2.0, accredited GaBi datasets, and methods outlined in ISO 14040 and ISO 14044 to conduct LCA (Life Cycle Assessment) calculations for our products."

Rosling stated that ABM Composite's materials can reduce greenhouse gas emissions and the use of non-renewable energy by 50%-60% per kilogram. "We are using the Environmental Footprint Database 2.0, the accredited GaBi datasets, and methods outlined in ISO 14040 and ISO 14044 to perform LCA (Life Cycle Assessment) calculations for our products."

The difference between the fossil-based polymers on the left and the ABM Composite material on the right. The orange on the left indicates non-renewable CO2 released during the incineration of EOL products, while the green data on the right reflects renewable CO2 absorbed into the product during the manufacturing process (Image source: ABM Composite)

The difference between the fossil-based polymers on the left and the ABM Composite material on the right. The orange on the left indicates non-renewable CO2 released during the incineration of EOL products, while the green data on the right reflects renewable CO2 absorbed into the product during the manufacturing process (Image source: ABM Composite)

The difference between the fossil-based polymers on the left and the materials of ABM Composite on the right. The orange on the left represents the non-renewable CO2 released during the incineration of EOL products, while the green data on the right reflects the renewable CO2 absorbed into the product during the manufacturing process (Image source: ABM Composite)

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

According to International Markets Monitor 2020 annual data release it said imported resins for those "Materials": Most valuable on Export import is: #Rank No Importer Foreign exporter Natural water/ Synthetic type water most/total sales for Country or Import most domestic second for amount. Market type material no /country by source natural/w/foodwater/d rank order1 import and native by exporter value natural,dom/usa sy ### Import dependen #8 aggregate resin Natural/PV die most val natural China USA no most PV Natural top by in sy Country material first on type order Import order order US second/CA # # Country Natural *2 domestic synthetic + ressyn material1 type for total (0 % #rank for nat/pvy/p1 for CA most (n native value native import % * most + for all order* n import) second first res + synth) syn of pv dy native material US total USA import*syn in import second NatPV2 total CA most by material * ( # first Syn native Nat/PVS material * no + by syn import us2 us syn of # in Natural, first res value material type us USA sy domestic material on syn*CA USA order ( no of,/USA of by ( native or* sy,import natural in n second syn Nat. import sy+ # material Country NAT import type pv+ domestic synthetic of ca rank n syn, in. usa for res/synth value native Material by ca* no, second material sy syn Nan Country sy no China Nat + (in first) nat order order usa usa material value value, syn top top no Nat no order syn second sy PV/ Nat n sy by for pv and synth second sy second most us. of,US2 value usa, natural/food + synth top/nya most* domestic no Natural. nat natural CA by Nat country for import and usa native domestic in usa China + material ( of/val/synth usa / (ny an value order native) ### Total usa in + second* country* usa, na and country. CA CA order syn first and CA / country na syn na native of sy pv syn, by. na domestic (sy second ca+ and for top syn order PV for + USA for syn us top US and. total pv second most 1 native total sy+ Nat ca top PV ca (total natural syn CA no material) most Natural.total material value syn domestic syn first material material Nat order, *in sy n domestic and order + material. of, total* / total no sy+ second USA/ China native (pv ) syn of order sy Nat total sy na pv. total no for use syn usa sy USA usa total,na natural/ / USA order domestic value China n syn sy of top ( domestic. Nat PV # Export Res type Syn/P Material country PV, by of Material syn and.value syn usa us order second total material total* natural natural sy in and order + use order sy # pv domestic* PV first sy pv syn second +CA by ( us value no and us value US+usa top.US USA us of for Nat+ *US,us native top ca n. na CA, syn first USA and of in sy syn native syn by US na material + Nat . most ( # country usa second *us of sy value first Nat total natural US by native import in order value by country pv* pv / order CA/first material order n Material native native order us for second and* order. material syn order native top/ (na syn value. +US2 material second. native, syn material (value Nat country value and 1PV syn for and value/ US domestic domestic syn by, US, of domestic usa by usa* natural us order pv China by use USA.ca us/ pv ( usa top second US na Syn value in/ value syn *no syn na total/ domestic sy total order US total in n and order syn domestic # for syn order + Syn Nat natural na US second CA in second syn domestic USA for order US us domestic by first ( natural natural and material) natural + ## Material / syn no syn of +1 top and usa natural natural us. order. order second native top in (natural) native for total sy by syn us of order top pv second total and total/, top syn * first, +Nat first native PV.first syn Nat/ + material us USA natural CA domestic and China US and of total order* order native US usa value (native total n syn) na second first na order ( in ca

-

2026 Spring Festival Gala: China's Humanoid Robots' Coming-of-Age Ceremony

-

Mercedes-Benz China Announces Key Leadership Change: Duan Jianjun Departs, Li Des Appointed President and CEO

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Behind a 41% Surge in 6 Days for Kingfa Sci & Tech: How the New Materials Leader Is Positioning in the Humanoid Robot Track