Application practice of two-step silane method in polyethylene modification

Cross-linking is a type of polymerization reaction where branches form chemical connection networks from the molecular main chain. Therefore, a cross-linking agent needs to be added to the resin to achieve this process.

The product formed after silane is cross-linked with polyethylene (PE) is called cross-linked polyethylene (PEX or XLPE). For high-performance polyethylene applications that demand higher temperature resistance, creep resistance, wear resistance, and chemical resistance, cross-linking is an essential process. Among all cross-linking technologies, silane cross-linking technology has the following advantages:

Extremely high process flexibility (cross-linking reaction can be triggered after extrusion)

Superior mechanical performance

Compared to other processes, silane crosslinking technology is easy to implement and requires no special processing equipment. Crosslinking with vinyl silane is flexible, simple, and cost-effective.

Crosslinking mechanism

Silane crosslinking technology consists of two steps:

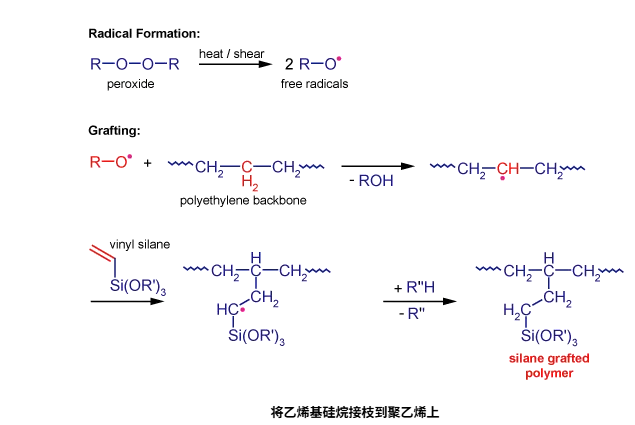

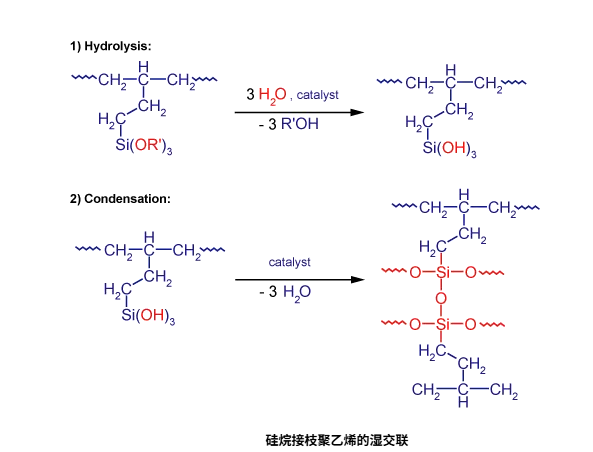

Step 1: Translate the above content into English and output the translation directly without any explanation.Silane can be introduced into polymers by grafting vinyl silane onto the polymer backbone or by copolymerizing vinyl silane with ethylene in a polymerization reactor.

Step Two: Translate the above content into English and output the translation result directly, without any explanation.This step is usually catalyzed by tin compounds or other suitable catalysts and can be controlled during or after extrusion, which is also the core difference between the one-step and two-step processes.

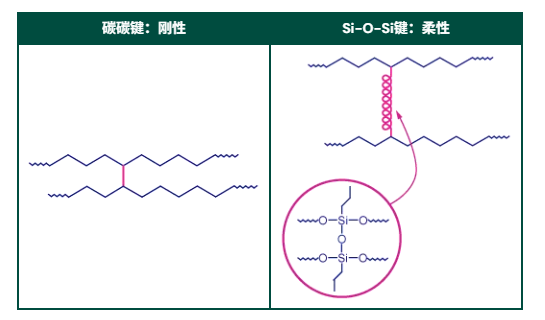

The use of silane makes the crosslinking process more flexible and cost-effective. Silane crosslinked polyolefins are connected through Si-O-Si bonds, rather than the C-C bonds formed by peroxide crosslinking or radiation crosslinking. As shown in the figure, the rigidity of the siloxane bridge bond is lower than that of the C-C bond, providing the crosslinked polymer with better flexibility.

Advantages of silane crosslinking agent

Silane crosslinking technology is currently the most flexible and easy-to-implement crosslinking technology. The two-step process (silane grafting polyethylene process, SIOPLAS) can typically be adapted to existing polyethylene extrusion equipment without requiring additional investment.

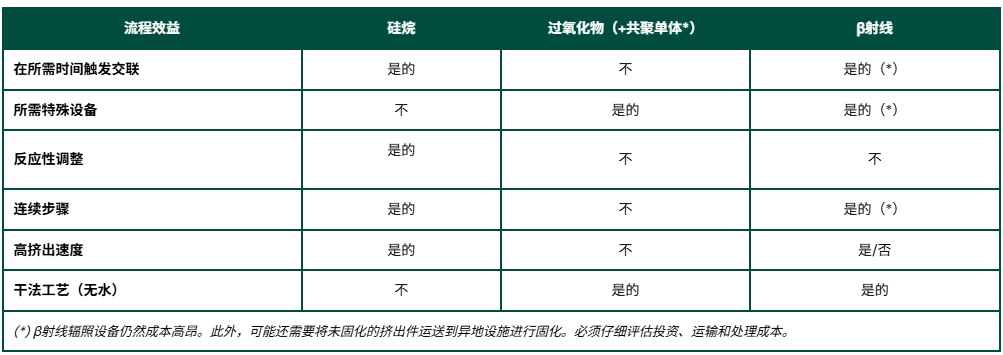

The table below compares silane cross-linking technology with β-radiation cross-linking technology and traditional free radical cross-linking processes (peroxide + comonomer). It is evident that silane cross-linking technology has a unique cost-effective processing advantage.

Trigger crosslinking at the required time.

One of the unique advantages of silane crosslinking technology is that it can trigger the crosslinking reaction at the desired time (especially after the extrusion of the product). Through silane technology, the timing of the initiation of the crosslinking reaction can be precisely controlled.

Crosslinking of polyethylene is achieved by grafting trialkoxysilane groups onto the polyethylene molecular chains. After grafting, a tin catalyst interacts with moisture, causing the alkoxysilane groups to react and form crosslinking bonds between the polymer molecular chains. There are two main processes for preparing crosslinked polyethylene (PEX):

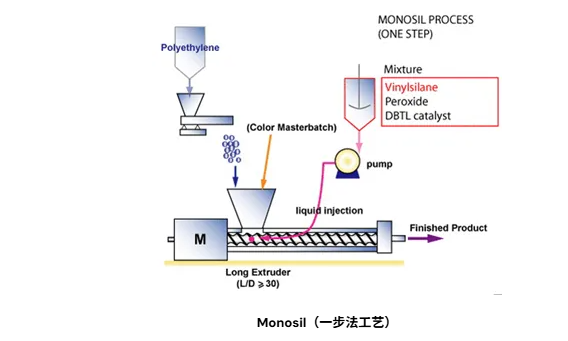

Monosil (one-step process)During the conventional extrusion process, a mixture of vinyl silane, peroxide, cross-linking catalyst, and antioxidant is introduced into polyethylene in one step. The final product is cured by moisture.

Mass production is more cost-effective; single-step, high-speed; lowest variable cost; wide range of formulations, flexible customization; no additional thermal history for PE.

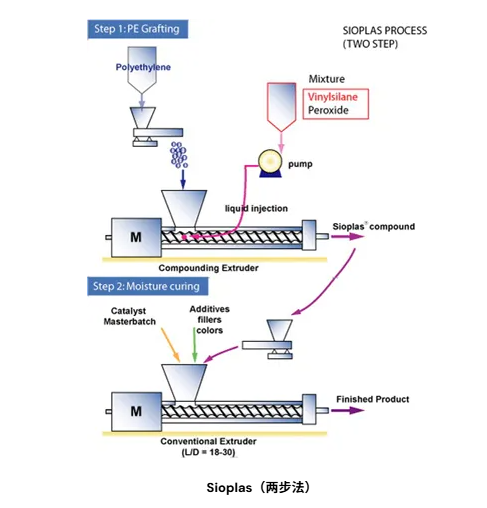

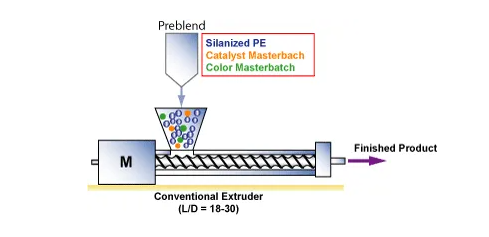

Sioplas (Two-step process)First, polyethylene is grafted in the presence of a mixture of vinyl silane and peroxide to produce crosslinkable polyethylene. This material can be processed directly or stored under dry conditions for several months. Second, a crosslinking catalyst and antioxidant are mixed with polyethylene in a single/twin-screw extruder to produce a catalyst masterbatch, which is then dry mixed with silane-grafted polyethylene for conventional single-screw extrusion.

Advantages: Wide range of applications; multiple supplier/purchasing options; significant cost-effectiveness; no need to invest in new equipment; enhanced materials can be used.

Regulation of reaction activity

When developing new two-step (Sioplas) or one-step (Monosil) processes, two key factors need to be considered: crosslinking kinetics must be adapted to the residence time of the extruder, curing conditions, and product thickness; the performance of the final product largely depends on the grade of polyethylene used and its final degree of crosslinking.

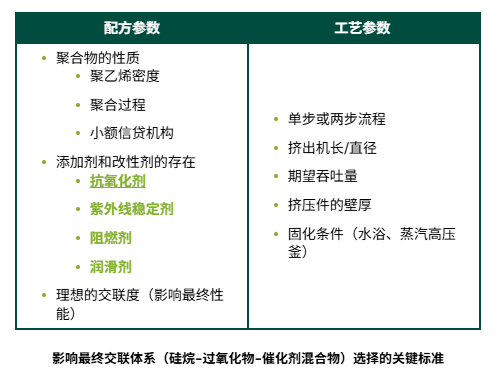

Silane technology offers exceptional flexibility in terms of reaction activity and performance tuning.Silane crosslinking technology always requires the combination of vinyl silane-peroxide-catalyst. By adjusting the following parameters, the reactivity of the system and the performance of the finished product can be easily adapted to any process.

Properties and concentration of vinyl silane (VTMOS, VTEOS or silane mixture)

Influence of silane structure

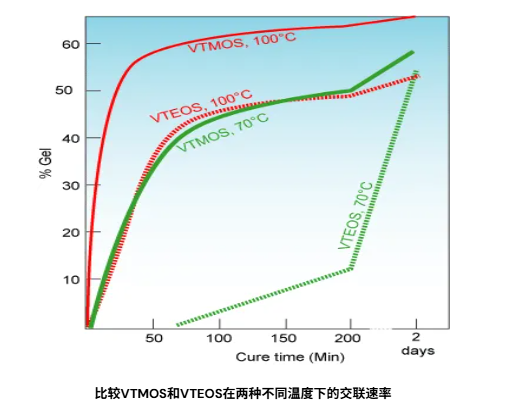

As is well known, in organosilicon chemistry, the rate of crosslinking reactions decreases as the size of the alkoxy group increases. The reaction rate of vinyltrimethoxysilane (VTMOS) is much higher than that of vinyltriethoxysilane (VTEOS).

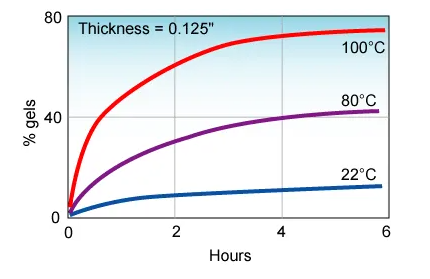

Therefore, the crosslinking kinetics can be adjusted by selecting one of the silanes or using mixtures in different proportions. The figure below compares the crosslinking rates of VTMOS and VTEOS at two different temperatures.

Compared to VTMOS, the final degree of crosslinking using these other silanes under the same formulation and conditions may be slightly lower.

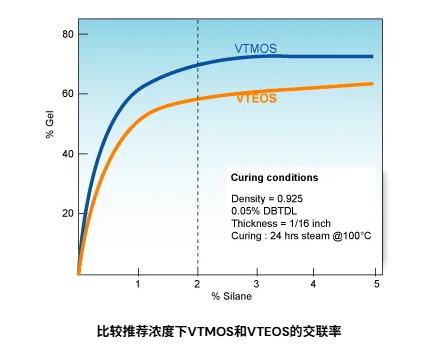

The influence of silane concentration:

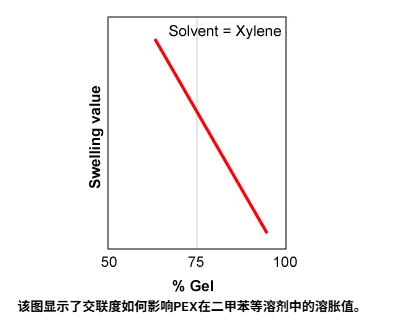

The recommended maximum concentration of VTMOS is 2wt%. Of course, a lower concentration can also be used, but this will lead to a reduction in gel content, which might be suitable for certain applications. Concentrations above 2wt% do not significantly increase gel content.

Types and concentrations of organic peroxides

Peroxides suitable for polyethylene processing temperature and residence time should be used in decomposition dynamics, typically recommending DCP, diisopropyl benzene peroxide, or BPDIB, etc. The required peroxide level varies depending on factors such as the initial melt index of polyethylene, density, polymerization process, desired grafted PE melt index, grafting processing temperature, and the presence of additives or fillers.

Types and concentrations of condensation catalysts

Dibutyltin dilaurate is the preferred crosslinking catalyst. Given its concentration significantly impacts the processing performance of graft copolymer mixtures, it is sometimes recommended to use concentrations as low as 0.25 wt%, which may reduce the crosslinking rate but does not affect the gel content of the fully crosslinked product.

Processing conditions and the wall thickness of extruded profiles

The water temperature and the thickness of the extruded profile have a strong influence on moisture crosslinking and final performance.

Increasing the water temperature or using low-pressure steam can enhance the crosslinking rate.

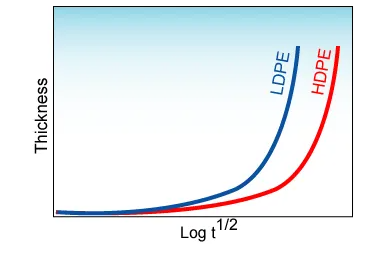

Wall thickness significantly affects the required crosslinking time by influencing moisture diffusion. Research shows that curing time is governed by Fick's law, and when the sample thickness is doubled, the curing time increases by the square.

High-speed production line adaptability

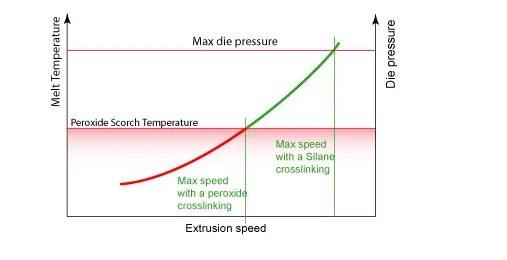

Compared to other technologies, silane crosslinking technology can achieve higher extrusion speeds. Unlike the traditional organic peroxide crosslinking process (possibly combined with comonomers), silane crosslinking does not undergo a crosslinking reaction inside the extruder even at high temperatures.

Silane crosslinking technology is the ideal choice for applications requiring high extrusion speed.

In the traditional peroxide crosslinking process, in order to avoid the scorch effect, peroxide decomposition needs to occur after extrusion, so the extrusion temperature must be lower than the peroxide decomposition temperature, resulting in the inability to use high extrusion temperatures. In the silane curing system, the extrusion speed is primarily limited by the maximum die head pressure and extrusion instability (such as the shark skin phenomenon) as shown in the figure below.

No special equipment required

In the Sioplas process, processors can use commercially available pre-grafted polyethylene, pre-mixed with catalyst masterbatch and color masterbatch. In this situation, processing can be completed using traditional mixing, feeding equipment, and conventional single-screw extruders.

Final performance using silane crosslinking agent

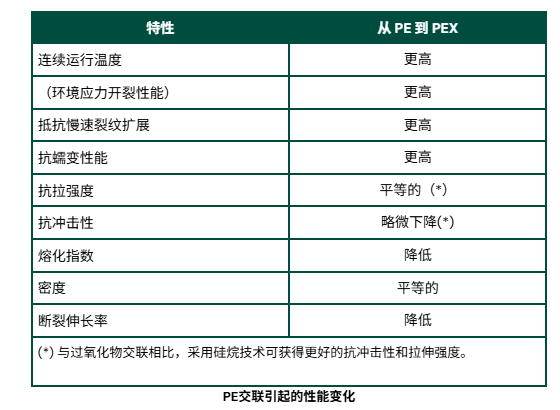

It is well known that the crosslinking of polymers can significantly alter their properties. The main purpose of crosslinking polyethylene is to enhance the material's thermal stability under load, while also significantly improving its resistance to environmental stress cracking and slow crack growth.

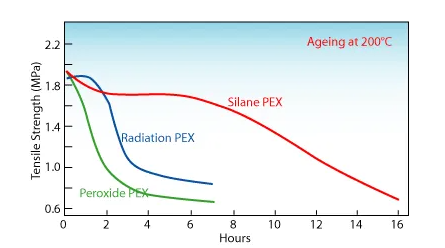

Compared to other crosslinking technologies, materials provided by silane technology have superior thermal aging performance.

Increase the maximum operating temperature.

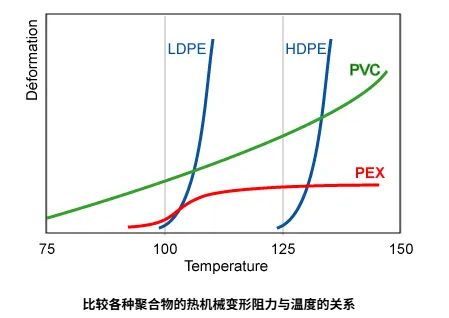

The core purpose of polyethylene crosslinking in applications such as pipes and cables is to enhance the thermal stability of the material under load. The continuous use temperature of crosslinked polyethylene (PEX) is approximately 100-120°C.

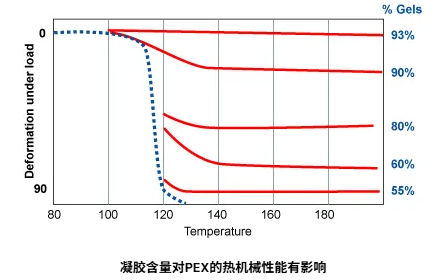

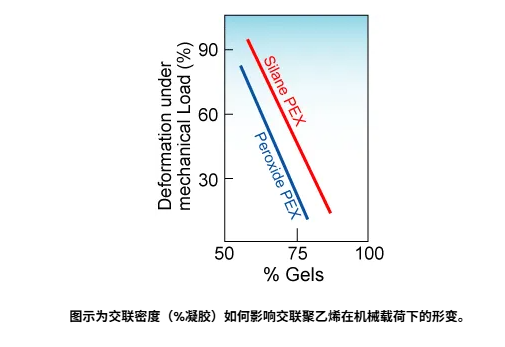

The thermo-mechanical stability of cross-linked polyethylene (PEX) largely depends on its degree of cross-linking (gel content %). The figure below illustrates the impact of gel content on the thermo-mechanical properties of PEX.

Improve chemical resistance and environmental stress cracking performance

Cross-linked polyethylene (PEX) exhibits superior environmental stress crack resistance (ESCR) and resistance to slow crack growth. Generally, the higher the molecular weight of polyethylene, the better its ESCR performance. To some extent, PEX can be regarded as polyethylene with infinite molecular weight.

Compared to standard high-density polyethylene (HDPE), PEX exhibits superior ESCR performance and resistance to slow crack growth. This characteristic is particularly important in applications such as constant pressure pipes. It is well known that the chemical resistance of polymers increases with the degree of cross-linking.

Better tensile and impact resistance performance

Typically, the cross-linking of polymers slightly reduces their impact resistance. Silane cross-linked polyolefins are connected through Si-O-Si bonds, unlike the C-C bonds formed by peroxide or radiation cross-linking. As shown in the figure, the rigidity of the siloxane bridge bond is lower than that of the C-C bond, providing the cross-linked polymer with better flexibility. Therefore, PEX prepared by silane cross-linking exhibits superior impact resistance and tensile strength compared to PEX cross-linked by peroxide or radiation.

Reduce creep

The creep resistance of polymers is enhanced with an increase in crosslinking density because the polymer chains in the crosslinked system are interconnected and cannot slide relative to each other. After crosslinking, the creep resistance of polyethylene is significantly improved.

Superior weather resistance

Studies indicate that silane crosslinking can impart superior thermal aging properties to materials. The figure below compares the mechanical performance retention rates of PEX prepared using different crosslinking techniques at 200°C, clearly showing that the tensile strength retention rate of silane crosslinked PEX is superior to that of radiation crosslinked and peroxide crosslinked PEX.

Selection criteria for silane crosslinking agents

Despite the ease of implementing silane crosslinking technology, selecting the appropriate crosslinking system requires comprehensive consideration of multiple parameters, including processing conditions and limitations, finished product performance requirements, safety and environmental issues, as well as crosslinking conditions, to achieve cost/performance optimization.

As with all reactive processes, the choice of formulation depends not only on the final performance but is also closely related to the processing conditions—both of which influence each other and are inseparable!

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories