Uhu city builds world's largest bdo industry base with 1.6 million tons under construction, accelerating layout of pbat and other bioplastics

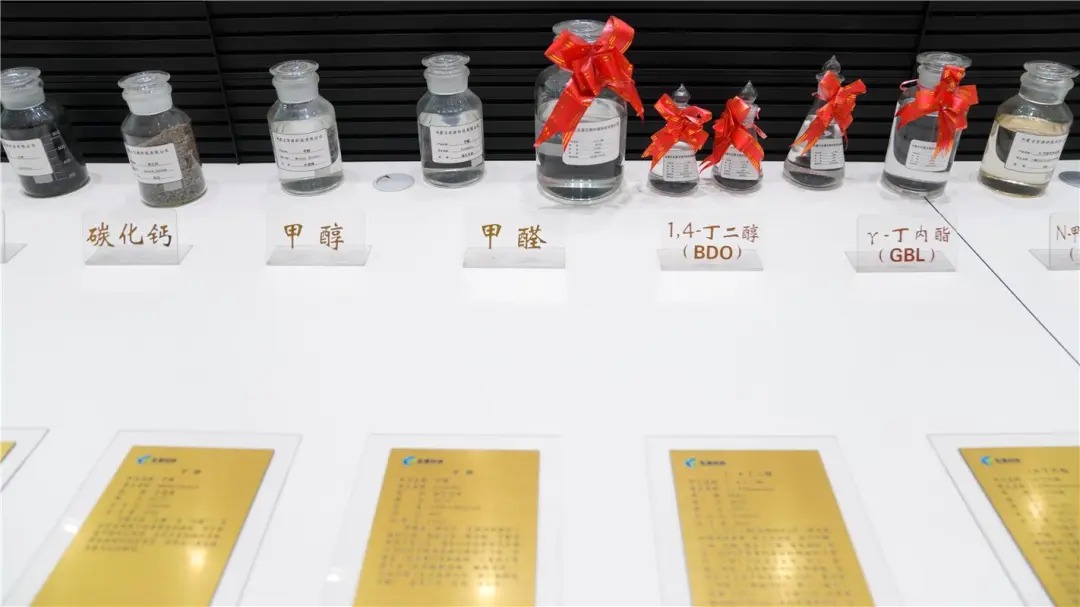

Wuhai City, a newly emerging industrial city in western Inner Mongolia, is leveraging its abundant coal and calcium carbide resources to fully develop the world's largest integrated BDO production base.

By 2025, Wuhai City has successfully attracted and constructed.Hua Heng, Jun Zheng, San Wei, Dong Jing, Guang JinFive integrated BDO projects and eight downstream supporting deep processing projects have been completed, with a total BDO production capacity of 1.6 million tons. Products are already exported to 25 countries and regions, including South Korea and Vietnam, making it a standout in the city's foreign trade exports. It is expected that by 2027, the BDO production capacity in Wuhai City will account for more than 30% of the national BDO total production capacity, with an output value exceeding 100 billion yuan.

01 Resource Endowment and Industrial Foundation: Wuhai BDOThe Foundation of Rise

Wuhai City is known as the "Pearl of the Yellow River" and "Sea of Black Gold," surrounded by three mountains and traversed by a flowing river. It produces coal and calcium carbide, with a coking capacity of 17.63 million tons and a calcium carbide capacity of 6.10 million tons.

Source: Wuhai News

According to estimates, Wuhai City is utilizing existing coking and calcium carbide production capacities, efficiently recycling coke oven gas and acetylene gas to develop BDO and downstream industries. Compared to directly selling calcium carbide, its output value increases by about 13 times, the added value increases by about 19 times, and energy consumption intensity decreases by more than 70%.

This data reveals the economic and environmental logic behind Wuhai City's vigorous development of the BDO industry. Wuhai City has a prospective limestone resource reserve of over 20 billion tons and is making every effort to build a green energy consumption base in and around the city while accelerating the construction of dedicated railway lines and other projects. The abundant supply of raw materials and the rich resources of production factors such as electricity and steam provide unparalleled development conditions for the BDO industry.

In 2025, the railway transport train for Wuhai BDO products was officially launched, and BDO production lines from Dongyuan, Sanwei, Huaheng, and Junzheng achieved high-load operation. The opening of the logistics channel further strengthened the competitiveness of Wuhai's BDO industry.

02 BDODownstream Application Map: From Chemical Raw Materials to Biodegradable Plastics

BDO (1,4-butanediol) is an important raw material in the fields of organic and fine chemicals, with a wide range of downstream applications. In the industrial layout of Wuhai, BDO is mainly used to manufacture four major categories of products:

Biodegradable materialsPBAT (polybutylene adipate terephthalate), PBS (polybutylene succinate)

Textile materialsPTMEG (polytetramethylene ether glycol), spandex, aramid

New energy materialsNMP (N-Methyl-2-pyrrolidone), lithium battery solvent

Specialty ChemicalsTHF (Tetrahydrofuran), GBL (Gamma-Butyrolactone), Pharmaceutical Intermediates

BDO derivatives have high added value, especially in the direction of biodegradable plastics, and have become a key focus of Wuhai's industrial transformation.

PBAT, as one of the best biodegradable plastic materials in market applications, has a melting point and mechanical properties comparable to traditional polyethylene (PE), along with excellent degradability, allowing it to be decomposed by natural microbes or enzymes into water and carbon dioxide in a relatively short time. The Regional Economic Cooperation Bureau of Wuhai City is also introducing downstream extension projects of the BDO industry and lithium battery separator projects, including PTMEG, spandex, aramid, biodegradable materials and their products, lithium battery separators, etc., to further improve the industrial chain layout.

03 Recent Wuhai Biodegradable Plastics Project

Guangjin BDO-PBATIntegration Project

Wuhai Guangjin New Materials Co., Ltd.'s BDO-PBAT integrated project has a total investment of approximately 7.25 billion yuan and will be constructed in two phases. The first phase involves the construction of a production line with an annual output of 300,000 tons of BDO, including a 120,000 tons/year calcium carbide acetylene unit, three 240,000 tons/year formaldehyde units, three 100,000 tons/year BDO units, a hydrogen production unit with a capacity of 28,000 standard cubic meters per hour, and supporting auxiliary facilities. Construction of the first phase commenced in April 2023. The second phase involves the construction of a production line with an annual output of 300,000 tons of PBAT.

As of May 2025, the piping installation for the main equipment of the project is nearing completion, and the installation of electrical instruments has begun. The main civil construction of auxiliary facilities has been completed, and secondary structural construction is underway. According to the plan, the project is expected to complete the installation of the main equipment in June 2025, and the calcium carbide unit will commence trial production in October 2025.

The project relies on Wuhai City's advantages in resources, energy, and industry to build a complete industrial chain of "coal, limestone—calcium carbide—BDO—biodegradable plastics."

Dongjing Zhongke 120 Ten thousand tons of PBATIntegrated Production Base

Wuda District of Wuhai City is leveraging its existing production capacity advantages of 120,000 tons of DMC, 100,000 tons of industrial silicon, and 680,000 tons of BDO. With Xiaocao Green Energy as the leading core engine, it is fully promoting the construction and commencement of Dongjing Zhongke's 1.2 million tons PBAT integrated production base, 200,000 tons of PBAT modification, and 100,000 tons of biodegradable material products project.

Once completed, this project will become the world's largest integrated PBAT production base.

Zhongke Klan PDAProject on Fully Natural Biodegradable Materials

On October 31, 2025, the first phase of Inner Mongolia Zhongke Kelan New Material Technology Co., Ltd.'s project to produce 33,000 tons of fully naturally biodegradable materials (PDA) per year, located in Wuhai High-tech Industrial Development Zone, reached a critical milestone with the completion of the main structure and the simultaneous entry of the first batch of production equipment.

The project will be constructed in two phases. The first phase will establish a complete set of facilities with an annual production capacity of 3,000 tons of PDA and supporting infrastructure in the plant area. The second phase will plan the construction of a complete set of facilities with an annual production capacity of 30,000 tons of PDA and its supporting engineering.

Source: Beijing Zhongke Kelan New Materials Technology Co., Ltd.

PDA is the core product independently developed by Beijing Zhongke Kelan New Material Technology Co., Ltd. It has outstanding performance and can completely degrade in all natural environments such as soil, compost, freshwater, and ocean without any microplastic residues. More than 60% of the production materials for this project come from BDO, fully utilizing the raw material advantages of Wuhai.

From project planning, company registration, land approval to commencement of construction, the project achieved main structure topping out in just 7 months. According to the plan, the installation of the first batch of equipment will officially begin by the end of November 2025, and trial runs will be completed by June 2026 to achieve continuous production of PDA materials. The second phase of the project has entered the preliminary preparation stage, aiming to achieve production effectiveness by the end of 2027.

04 Industrial Chain Collaboration and Cluster Effect

Wuhai City has achieved a complete layout from raw materials to end products through the vertical integration of the BDO industry chain.Already formedBDO—Spandex, BDO—Lithium battery solvent, BDO—Biodegradable plasticsEngineering plastics, BDO—Pharmaceutical intermediates and other entire industry chainsWuhai City's greatest advantage in developing the BDO industry lies in its ability to create a closed-loop industrial chain. This allows for a transformation from "a piece of coal" to "a strand of silk" and finally to "a bolt of fabric," driving the entire BDO industrial chain towards end-use applications.

Currently, Wuhai City has completed the entire chemical industry chain from coking, methanol, BDO to biodegradable materials (PBS, PBT, PTMEG, PBAT).“ Limestone—Calcium Carbide—BDO—Biodegradable materials—High-end functional film materialsA complete industrial chain is taking shape.Wuhai City is actively introducing a diaphragm project, planning to build a lithium battery diaphragm production line with an annual capacity of 300 million square meters and a total investment of 1 billion yuan, further expanding its layout in the new materials field.

Despite the rapid development of the BDO industry in Wuhai City, it also faces some challenges.How to locally utilize the enormousBDO The key issue is that the Wuhai City Regional Economic Cooperation Bureau plans to focus on BDO downstream derivatives, further extending, supplementing, and strengthening the chain, and attracting investment for downstream projects.

Edited by: Lily

Source materials: Wuhai Media Center, Biodegradation Research Institute, Inner Mongolia News Network, China National Radio, Xinhua News Agency, Guangming Online, etc.

【Copyright and Disclaimer】This article is the property of PlastMatch. For business cooperation, media interviews, article reprints, or suggestions, please call the PlastMatch customer service hotline at +86-18030158354 or via email at service@zhuansushijie.com. The information and data provided by PlastMatch are for reference only and do not constitute direct advice for client decision-making. Any decisions made by clients based on such information and data, and all resulting direct or indirect losses and legal consequences, shall be borne by the clients themselves and are unrelated to PlastMatch. Unauthorized reprinting is strictly prohibited.

Most Popular

-

Zf asia-pacific innovation day: Multiple Cutting-Edge Technologies Launch, Leading Intelligent Electric Mobility

-

Fire at Sinopec Quanzhou Petrochemical Company: 7 Injured

-

DuPont plans to sell Nomex and Kevlar brands for $2 billion! Covestro Declares Force Majeure on TDI / oTDA-based / Polyether Polyol; GAC Group Enters UK Market

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories

-

Engel initiates 10+ eu anti-dumping complaints seeking trade protection for pvc, abs, polyolefins and other products