The Lightweight Automotive Breakthrough: Why Seres Is Most Optimistic About Magnesium Alloys?

Image source: Seres

In the silent war of lightweighting in the new energy vehicle sector, while many car manufacturers are still hesitating over the choice of materials like aluminum alloys and carbon fiber, why has Seres bet on magnesium alloys, which the industry is watching with caution? As lightweighting gradually shifts from a "bonus item" to a "must-answer question" that determines the range and efficiency of vehicle models, what confidence does Seres have in making magnesium alloys the essential choice for automotive lightweighting?

Why is Seres betting on magnesium alloys?

Magnesium alloy is hailed as the "green engineering material of the 21st century," but its large-scale application in the automotive industry has long faced three major technical challenges: flammability, insufficient corrosion resistance, and complex forming processes. However, SERES’ choice is not a blind gamble but is based on systematic technological breakthroughs.

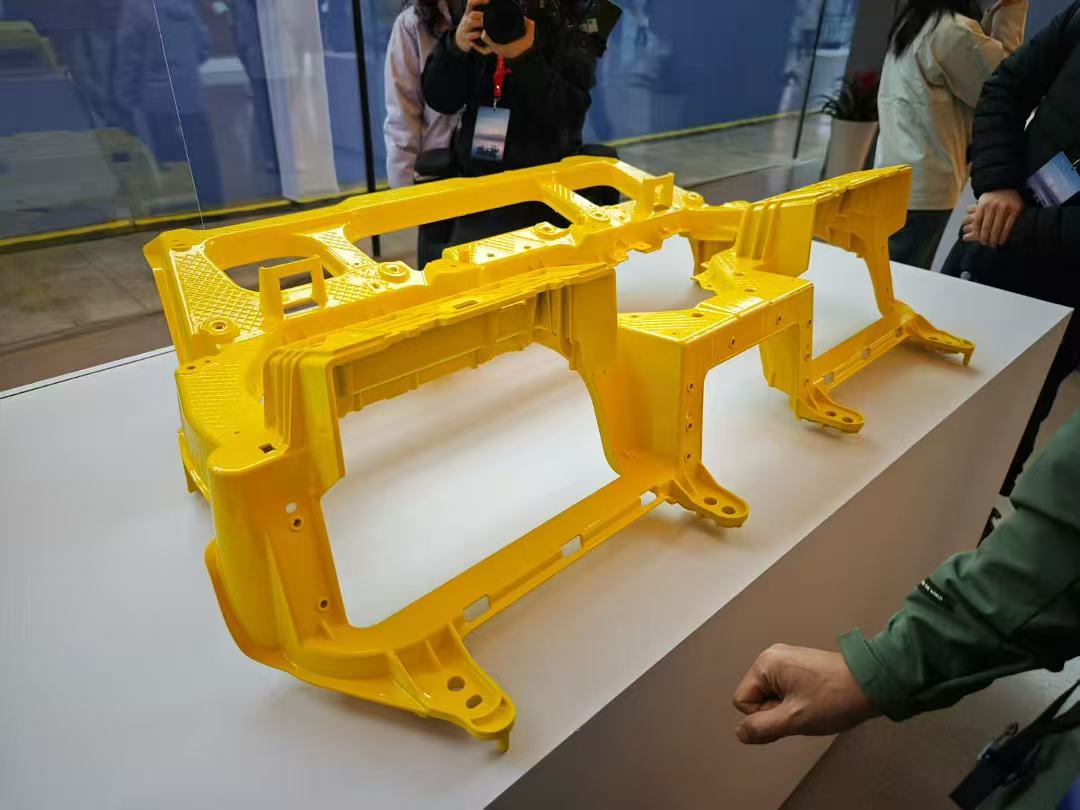

In April 2025, the ultra-large integrated die-cast magnesium alloy rear car body, jointly developed by Seres, Chongqing University, Baowu Magnesium Industry, and the University of Science and Technology Beijing, was officially unveiled. The successful trial production of the Seres ultra-large integrated die-cast magnesium alloy rear car body white body marks the official transition of the magnesium alloy rear car body from components to complete vehicles and from the laboratory to mass production applications.

It is important to note that this seemingly ordinary white body component is backed by the resolution of 48 key technical challenges, among which 12 have achieved breakthroughs from "0 to 1" in the industry. Compared to traditional aluminum alloy rear car bodies, the new structure achieves a weight reduction of 21.8% and an overall performance improvement of over 10%.

The core of technological breakthroughs lies in process innovation. Baowu Magnesium Industries has developed a large vertical furnace magnesium smelting technology that increases single furnace output, reduces energy consumption by 30%, and achieves the lowest cost in the industry. Notably, with the supporting 300,000-ton silicon iron production capacity (scheduled to be operational in 2026), it will achieve self-sufficiency in key materials for primary magnesium production, further driving down costs.

The more critical breakthrough is in corrosion resistance. In July 2024, Silversun and Huichuan Joint Power released the world's first magnesium alloy motor casing, which, through a special alloy formula and surface treatment, addresses the corrosion issues in high humidity and salt fog environments, allowing for the application of exposed components for the first time. This breakthrough increases the potential application space of magnesium alloy per vehicle from 14 kg to 88 kg, opening up a market with fivefold growth potential.

With the advancement of the "dual carbon" goals, one of the truly effective means to achieve energy saving and emission reduction is lightweighting, and one of the most effective materials for lightweighting is magnesium alloy. Pan Fusheng, academician of the Chinese Academy of Engineering, chairman of the Chongqing Association for Science and Technology, and professor at Chongqing University, pointed out that "the current maturity of magnesium alloy technology can achieve applications of over 50kg per vehicle, and moving towards applications of over 100kg or 200kg in the future will require more technological breakthroughs."

Academician Pan Fusheng's judgment is not unfounded. Cyrus's technological moat is reflected in its systematic layout of "materials - processes - products." From new material formulas to new casting processes, from connection technologies to anti-corrosion systems, Cyrus has formed a comprehensive coverage of multiple patents, papers, and standards across all links, establishing a key support for the national industrial security barrier.

Image source: Gaishi Auto Photography

Magnesium alloy plays a crucial role in lightweighting.

Technical feasibility is only the first step; economic viability is the key to large-scale adoption. Data shows that magnesium is 1/3 lighter than aluminum, with current prices at 17,000 yuan/ton for magnesium and 20,000 yuan/ton for aluminum. Using magnesium for the same parts is 30% cheaper. The price advantage of raw materials is one of the important reasons for the future popularization of magnesium alloys.

This cost advantage is particularly evident in the application of complete vehicles. Taking the electric drive casing as an example, a magnesium alloy casing can reduce weight by nearly 7 kilograms compared to an aluminum alloy, with a cost saving of nearly 200 yuan per unit. Researchers have estimated that a certain model currently uses about 20 kilograms of magnesium per vehicle, allowing users to save over 2000 yuan in electricity costs annually. Once the processing costs are diluted at scale, the initial difference in processing fees, which is 30%-50% higher than aluminum, will be absorbed.

Seres had anticipated this situation long ago. Several years ago, when magnesium prices were still high, Seres systematically planned the development of advanced magnesium alloys. This strategic foresight paid off in 2024. With magnesium prices remaining below aluminum prices for almost a year, the enthusiasm for downstream applications was activated.

Baowu Magnesium, as a core supplier, has expanded its primary magnesium production capacity to 500,000 tons and magnesium alloy production capacity to 600,000 tons, which is sufficient to support downstream demand growth. With 70% of the world's magnesium produced in China, and abundant dolomite reserves, the country controls the pace of extraction to ensure both quantity and price stability. This provides Seres with a stable supply chain guarantee.

Certainly, if the sole purpose is weight reduction, carbon fiber can achieve the same result, but its high cost limits widespread use. Seres values the balance between lightweight characteristics and overall performance offered by magnesium alloy.

First of all, it's about extreme lightweighting. Magnesium alloy has a density that is 2/3 that of aluminum, making it 36% lighter than aluminum and 77% lighter than steel. The large one-piece die-cast magnesium alloy rear body of the Seirrus reduces weight by 21.8%, which directly translates to an increase in driving range. In today's context, where "range anxiety" for electric vehicles has not been completely eliminated, every kilogram of weight reduction means a significant decrease in battery costs.

Secondly, there is an improvement in safety performance. The magnesium alloy rear body is not only lighter but also enhances overall performance by more than 10%. Its specific strength is higher than that of aluminum alloy, showing excellent performance in collision energy absorption and structural rigidity. More critically, the electromagnetic shielding performance is doubled, which is crucial for the dense electronic systems in smart electric vehicles, reducing electromagnetic interference and thereby enhancing system reliability. Additionally, the damping and shock absorption effect is increased by 25 times, contributing to improved driving comfort.

Furthermore, there is the value of green manufacturing. A 15% reduction in carbon emissions over the entire lifecycle aligns with the global carbon neutrality trend and fits with Cyres' positioning of "green and key strategic materials." In the context of the imminent implementation of carbon tariffs in Europe, reducing carbon emissions at the material level directly enhances product competitiveness.

As industry experts believe, lightweighting is the key path to improving the energy efficiency of new energy vehicles. Through the use of magnesium alloys, Seres not only achieves weight reduction but also enhances safety, comfort, and environmental protection. This systemic advantage elevates magnesium alloys from "alternative materials" to "strategic materials."

Image source: Shot by Gasgoo.

Full industry chainStarting to win the battle of lightweighting.

From a global perspective, the reason why Seeress is heavily investing in magnesium alloys in the field of lightweighting is that it has established a complete ecosystem from materials to processes.

Seres has deeply partnered with Baowu Magnesium Industry, a global leader in materials. Baowu Magnesium provides a full range of magnesium alloy solutions for the AITO series, with magnesium alloy production capacity expected to reach 600,000 tons by 2025, capturing over 35% of the global market share. It possesses a dolomite mine reserve of 1.75 billion tons, capable of extracting 230 million tons of magnesium metal, ranking first in the world. This strategic positioning in upstream resources ensures Seres' initiative in material supply.

At the process end, Seres collaborates with top institutions such as the Beijing Key Laboratory of Metal Lightweight Forming and Manufacturing at University of Science and Technology Beijing, mastering the large tank vertical magnesium smelting technology. More importantly, Seres has mastered core processes such as semi-solid injection molding and integrated die-casting, with yield rates approaching those of aluminum parts.

In terms of products, Seres' application depth is rare in the industry. Currently, the number of magnesium alloy parts used in the AITO series models has exceeded 10, with an application weight reaching the 20 kg level. This is not simply a matter of replacing parts but a systematic design restructuring. From the electric drive housing and shock absorber tower to the rear car body, Seres has extended the application of magnesium alloys from covering parts to structural components, integrating scattered parts into unified components. This evolutionary path from individual parts and assemblies to the entire vehicle effectively unleashes the systemic benefits of lightweight design.

The collaborative innovation model of industry, academia, and research is another important layout for Seres. According to Gaishi Automotive, during the Fifth Lightweight Conference, Seres, in collaboration with various organizations, showcased over 600 innovative exhibits and more than 240 customized solutions. The model, which is government-led, enterprise-driven, and supported by academia, enables Seres to quickly transform laboratory results into mass-produced products.

Image source: Seres

It is worth noting that Seres is not just paying lip service to its optimism about magnesium alloy, but has a clear timeline and roadmap.

According to the latest disclosed information, Seres currently uses about 20 kilograms of magnesium per vehicle, which far exceeds the industry average. In 2026, they plan to add mass production of electric drive housings (weighing 20 kilograms each), with a target of reaching 40 kilograms of magnesium per vehicle. In 2027, they plan to add a thick floor (weighing 45 kilograms each), with a target of reaching 90 kilograms of magnesium per vehicle. This means that within two years, Seres aims to increase the use of magnesium alloys by 3.5 times.

Information shows that the electric drive housing has been implemented across platforms such as Xpeng, Zeekr, Great Wall, and Seres, proving the maturity of magnesium alloy technology and the reliability of the supply chain. Testing of larger components such as the thick floorboard and inner door panels indicates that Seres is breaking through the ceiling of magnesium alloy applications.

Magnesium alloys have even more potential for innovation in lightweight applications. It is reported that robots and low-altitude aircraft have also begun to mass-test magnesium alloy structural components, showing significant advantages in weight reduction and heat dissipation. This means that the magnesium alloy technology accumulated by Seres can potentially extend to more high-growth sectors in the future.

Gai Shi Summary:Redefining LightweightGame Rules

In today's competitive landscape of new energy vehicles entering the second half, lightweighting is no longer just a simple technological optimization, but a strategic choice that concerns survival. Seres' magnesium alloy strategy is paving a way for the Chinese new energy vehicle industry to break through in materials.

It should be noted that this kind of bet is not risky, but rather based on a comprehensive judgment of technological maturity, cost inflection point, performance superiority, and complete ecosystem. From 20 kilograms to 90 kilograms, perhaps magnesium alloy for Seres has long surpassed the application of a single material and is instead a concentrated embodiment of its technological confidence, strategic determination, and industrial ambition.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

BASF Signs Another Giant: Covestro Already Set Up, Just Missing Wanhua Chemical?

-

DuPont plans to sell Nomex and Kevlar brands for $2 billion! Covestro Declares Force Majeure on TDI / oTDA-based / Polyether Polyol; GAC Group Enters UK Market

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories

-

Pop mart's half-year net profit soars by 363%! from pla to faux fur fiber, these core suppliers and material technologies are worth noting

-

Ministry Of Commerce Releases Implementation Opinions On Green Trade, Focusing On Import And Export Of Biodegradable Materials And Other Products