Qixiang Tengda Net Profit Plummets Over 2,183% with Losses Reaching 660 Million Yuan

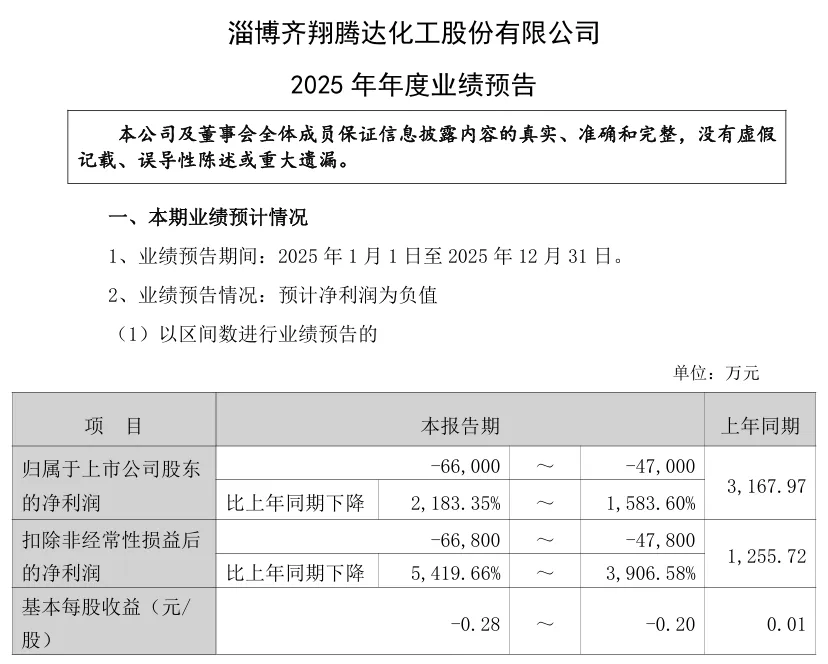

Recently, Qixiang Tengda released its 2025 annual results forecast, estimating a net profit attributable to shareholders of the parent company ranging from a loss of 470 million yuan to 660 million yuan, compared to a profit of 31.6797 million yuan in the same period last year. The estimated non-recurring net profit loss ranges from 478 million yuan to 668 million yuan, compared to a profit of 12.5572 million yuan in the same period last year.

Reasons for Changes in Performance

Qixiang Tengda stated that during the reporting period, due to the slowdown in global economic growth and the weaker-than-expected recovery of domestic demand, the chemical product market was generally at a cyclical low. The company's performance showed a "high in the first half, low in the second half" fluctuating trend. Facing market pressure, the company continuously promoted cost reduction and efficiency improvement, technological transformation, and lean management, optimized production scheduling and product structure, strengthened supply chain bargaining power, and strictly controlled various expense expenditures.

Despite short-term performance pressures, the company remains committed to advancing industrial chain synergy and technological innovation, proactively building capacity and technical reserves for an industry recovery, aiming to solidify long-term competitive barriers at the bottom of the cycle.

Currently, Qixiang Tengda boasts a design capacity of 260,000 tons/year for methyl ethyl ketone (MEK), making it the world's largest MEK production facility, with its output and sales consistently ranking first globally. Its maleic anhydride (MA) plant has a capacity of 400,000 tons/year, maintaining a stable domestic market share of approximately 30%, highlighting its significant scale advantages. The company's propylene oxide (PO) plant has a design capacity of 300,000 tons/year and is currently operating at full capacity, achieving a balance between production and sales. Additionally, it has a co-located 205,000 tons/year high-concentration hydrogen peroxide plant and an upstream 700,000 tons/year propane dehydrogenation to propylene (PDH) plant, ensuring a stable supply of raw materials for propylene oxide production.

It is reported that Qixiang Tengda's propylene oxide (PO) plant utilizes the Hydrogen Peroxide to Propylene Oxide (HPPO) technology jointly owned by Germany's Evonik and ThyssenKrupp. This process offers significant advantages, including high atom economy, mild reaction conditions, and water as the sole by-product, which substantially reduces energy consumption and environmental pressure compared to the traditional chlorohydrin process. With the current continuous rise in propylene oxide prices, coupled with the company's stable self-supply of raw materials, product profit margins have expanded further, providing positive support for the company's performance.

It is worth mentioning that, recently, Qixiang Tengda stated during a targeted survey that the company is currently continuously exploring new downstream application scenarios for its products, such as the application of methyl ethyl ketone in electronic cleaning, maleic anhydride in new environmentally friendly board materials, high-purity anhydrous tert-butanol in semiconductor photoresist diluents, and propylene oxide in new energy vehicle seat filling materials. At the same time, the company is promoting key technological breakthroughs through independent research and development, cooperation with scientific research institutions and universities, and accelerating the transformation of scientific and technological achievements. Currently, relying on the advantages of its existing MMA products, the company is steadily extending into downstream high-performance resin materials such as PMMA, and has initiated small-scale PMMA technology cooperation with scientific research institutions, with plans to advance pilot-scale and industrialization research in the future.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

EU Changes ELV Regulation Again: Recycled Plastic Content Dispute and Exclusion of Bio-Based Plastics

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories