Physical Recycling Breakthrough for PA6: Automotive Component Application Validation

Polyamide (PA) has excellent mechanical properties, is easy to process, and is corrosion-resistant, making it widely used in automotive, marine, and other fields.However, PA is non-biodegradable, and discarded fishing nets based on PA6 account for about 10% of marine waste plastic, causing serious pollution. The recycling of waste PA mainly includes three approaches: energy recovery, physical recovery, and chemical recovery. Energy recovery has low efficiency and high carbon emissions, chemical recovery has high costs and is difficult to promote, while physical recovery is the most widely applied. However, the quality and added value of recycled products are relatively low, requiring the addition of new materials and additives to enhance performance.

For the purpose of achieving lightweight design, composite material solutions are proposed in this paper, as most automotive deflector brackets are made of stamped steel plates or cast aluminum and other metal materials.Mix post-consumer recycled polyamide (PCR-PA6) with virgin polyamide (VPA6) at different ratios through physical blending, followed by melting, extruding, and pelletizing, to test and analyze changes in material properties.,Screen and validate suitable ratios to provide feasible solutions and data support for the reuse of PCR-PA6 in automotive products.。

1Experiment Section

1.1

Main raw materials

PA6, HY-2500A, Jiangsu Haiyang Chemical Fiber Co., Ltd.

PCR‐PA6, L.B.NLB007A, Funing Jinyu Plastics Co., Ltd.

Fiberglass, T435, Taishan Fiberglass Co., Ltd.

Antioxidants, a mixture of hindered phenolic antioxidants and phosphite esters 1098 and 168, available on the market.

Ultraviolet absorbers and light stabilizers, benzotriazole type UV‐234 and hindered amine type UV‐944 mixture, commercially available.

Release agent, ethylene-acrylic acid copolymer AC-540A, Honeywell International Inc., USA.

1.2

Main Equipment and Instruments

Twin-screw extruder, TE65, Nanjing Keya Company.

Plastic injection molding machine, HTF90 W1, Ningbo Haitian Plastics Machinery Group Co., Ltd.

Tensile testing machine, LJ series, Hebei Chengde Testing Machine General Factory.

Pendulum Impact Testing Machine, HIT25P, Zwick Company.

Vicata Heat Deflection Tester, 40-197-100, COESFELD Company;

Differential Scanning Calorimeter (DSC), DSC3, METTLER TOLEDO Company.

Walk-in temperature and humidity test chamber, AZTH9U, Shanghai Zengda Technology Co., Ltd.

High Temperature Test Chamber, AZHEAT3, Shanghai Zengda Technology Co., Ltd.

Deuterium lamp aging tester, Ci4400, ATLAS Company, USA; standard light source box, Judge QC, X-Rite Company, USA.

1.3

Sample preparation

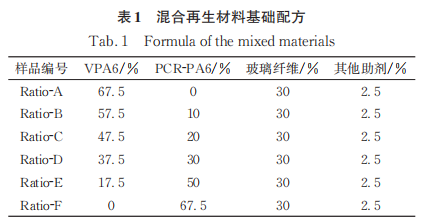

Mix VPA6, PCR-PA6, and the modifier in a mass ratio evenly and add them to the main feed port of a twin-screw extruder. Add glass fibers in a mass ratio to the side feed port, and obtain modified plastic granules of PA6-GF30 composite materials with 0%, 10%, 20%, 30%, 50%, and 67.5% recycled content through melt blending and extrusion granulation. After drying the PA6-GF30 modified plastic granules at 100°C for 4 hours, pour them into an injection molding machine to mold test specimens. Set the temperature of sections 1 to 3 to 225°C, 260°C, and 270°C, respectively, with a mold temperature of 100°C, and an injection pressure of 100-160 MPa. The basic formulations of the six mixed recycled materials are shown in Table 1.

1.4 Performance testing and structural characterization

Tensile strength, tensile modulus, and elongation at break were tested according to the methods specified in GB/T 1040.2-2022, with a tensile rate of 5 mm/min and a specimen type of 1A. Flexural strength and flexural modulus were tested according to the methods specified in GB/T 9341-2008, with a rate of 2 mm/min, a span of 64 mm, and specimen dimensions of (80±2) mm × (10±0.2) mm × (4±0.2) mm. The Charpy notched impact strength was tested according to the methods specified in GB/T 1043.1-2008, using a 4 J pendulum, with a span of 62 mm and specimen dimensions of (80±2) mm × (10±0.2) mm × (4±0.2) mm, and the notch type selected was type A. For the low temperature test, the specimen was placed in a low-temperature chamber at (−30±2) ℃ for at least 4 hours, and testing was completed within 5 seconds after removal. Heat distortion temperature was tested according to the methods specified in GB/T 1634.2-2019, with a load pressure of 1.80 MPa, a starting temperature of room temperature (should be below 27 ℃), and a heating rate of (120±10) ℃/h, with specimen dimensions of (80±2) mm × (10±0.2) mm × (4±0.2) mm. The melting point was tested using the DSC method according to ISO 11357-3-2018, under N₂ protection, with a heating rate of 20 ℃/min from 50 ℃ to 300 ℃, holding for 5 minutes to eliminate thermal history, then cooling down to 50 ℃, and reheating at a rate of 20 ℃/min to 300 ℃ to obtain the heating curve.

02 Results and Discussion

2.1Stretching Performance Analysis

From Figure 1, it can be seen that when the PCR-PA6 content is 0 (composition A), the material's tensile strength is 189 MPa, tensile modulus is 9980 MPa, and elongation at break is 3.3%. As the PCR-PA6 content increases, the overall tensile mechanical properties of the material show a downward trend. When the content does not exceed 20%, the material's properties do not change significantly compared to the new material. When the addition ratio exceeds 30%, the material's tensile mechanical properties decline significantly. For instance, when the PCR-PA6 content is 67.5% (composition F), meaning the entire plastic matrix in the modified plastic is PCR material, the tensile strength is 161 MPa, tensile modulus is 9460 MPa, and elongation at break is 2.8%. Compared to composition A, the tensile strength decreases by 14.81%, tensile modulus decreases by 5.21%, and elongation at break decreases by 15.15%. This is mainly due to the complex degradation, cross-linking, and other aging reactions that occur during the service period under the influence of natural factors such as load, light, heat, water, and oxygen, leading to a decline in the material's overall performance, which becomes more pronounced as the PCR-PA6 content increases.

Relatively speaking, the tensile strength and elongation at break of the material decrease more significantly, while the tensile modulus decreases less.This may be due to the dominant effects of the proportion and orientation of glass fibers in modified plastics, as well as the interfacial bonding strength between the glass fibers and the plastic matrix, on the material's elastic modulus.。

Figure 1 Effect of PCR-PA6 content on the tensile properties of PA6-GF30

2.2 Bending performance analysis

From Figure 2, it can be seen that when the content of PCR‐PA6 is 0 (formulation A), the material's flexural strength is 259 MPa and the flexural modulus is 8530 MPa. As the content of PCR‐PA6 increases, the material's flexural strength shows a decreasing trend. Theoretically, the material's flexural modulus should also decrease, but the test data shows a phenomenon of first decreasing and then increasing. When the PCR‐PA6 content is 30% (formulation D), the material's flexural modulus is at its lowest, decreasing by only 1.99% compared to formulation A. This performance deviation may be due to fluctuations during the granulation, injection molding, or testing processes. When the PCR‐PA6 content is 67.5% (formulation F), the material's flexural strength is 221 MPa and the flexural modulus is 8480 MPa. Compared to formulation A, the flexural strength decreases by 14.67% and the flexural modulus decreases by 0.59%.

Figure 2 Effect of PCR-PA6 content on the bending properties of PA6-GF30.

2.3 Impact Performance Analysis

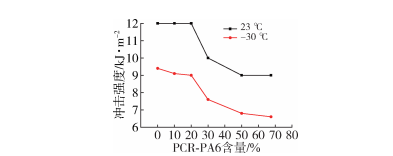

Impact resistance, as a core testing method for evaluating the toughness of plastics, is used to measure the material's resistance to fracture under high-speed impact conditions. It provides an analytical basis for the failure reasons of automobiles under impact load conditions [16]. As shown in Figure 3, when the PCR-PA6 content is 0 (formulation A), the notched impact strength of the simply supported beam is 12 kJ/m², and the low-temperature notched impact strength is 9.4 kJ/m². As the PCR-PA6 content increases, the overall impact performance of the material shows a declining trend. When the PCR-PA6 content does not exceed 20%, the material's performance changes relatively little compared to new materials. For example, in formulation C, the notched impact strength of the simply supported beam and the low-temperature notched impact strength are 12 kJ/m² and 9 kJ/m², respectively. Compared to formulation A, the notched impact strength of the simply supported beam remains unchanged, while the low-temperature notched impact strength decreases by 4.26%. However, when the PCR-PA6 content is 67.5% (formulation F), the notched impact strength of the simply supported beam is 9 kJ/m², and the low-temperature notched impact strength is 6.6 kJ/m². Compared to formulation A, the notched impact strength of the simply supported beam decreases by 25.00%, and the low-temperature notched impact strength decreases by 29.79%, indicating a significant drop.

Figure 3 Impact of PCR-PA6 Content on the Impact Performance of PA6-GF30

2.4Thermal performance analysis

From Figure 4, it can be seen that as the PCR-PA6 content increases, the thermal performance of the material changes little. When the PCR-PA6 content is 0 (composition A), the melting point and heat distortion temperature of the material are 221°C and 205°C, respectively. When the PCR-PA6 content is 67.5% (composition F), the melting point and heat distortion temperature of the material are 220°C and 202°C, respectively, with a decrease ratio of 1.46% and 0.45%. It can be seen that the addition of PCR-PA6 has little impact on the melting point and heat distortion temperature of PA6-GF30 modified plastics.

Figure 4 Impact of PCR-PA6 Content on the Thermal Performance of PA6-GF30

2.5Parts Design and Simulation Analysis

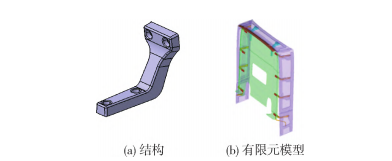

Due to the addition of recycled plastics, the material properties decline, necessitating the incorporation of additive agents for modification. However, excessive use of these agents can increase material costs, so an appropriate ratio of PCR plastic should be selected based on actual usage requirements. According to the performance-related standards for automotive duct support brackets, a PA6-GF30 recycled plastic containing 20% PCR-PA6 is chosen as the raw material. Structural design is carried out, and finite element modeling is performed using Hypermesh software, as shown in Figure 5.

Figure 5: Structure of the duct support and finite element model.

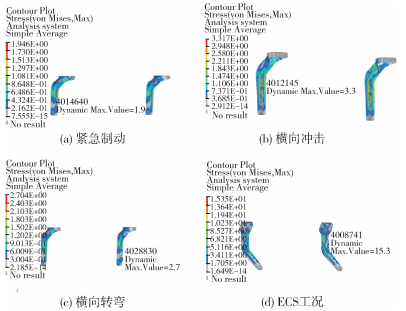

The structure contains 4 bolt assembly points, embedded with steel bushings, achieving the connection between the shroud and the cab body through bolt assembly. A 6×6 shell element mesh division is used, and the bolt connection parts adopt a bolt connection method. The model consists of a total of 5.24 million elements. Material properties are assigned to various parts of the model, and loading and constraint settings are carried out according to design requirements for CAE strength simulation analysis. The stress distribution is shown in Figure 6.

Figure 6 CAE Strength Finite Element Analysis Results

According to the simulation analysis results, the maximum stresses on the flow guide bracket under emergency braking, lateral impact, lateral turning, and ESC conditions are 1.9, 3.3, 2.7, and 15.3 MPa, respectively, which meet the design requirements.

2.6Component Performance Analysis

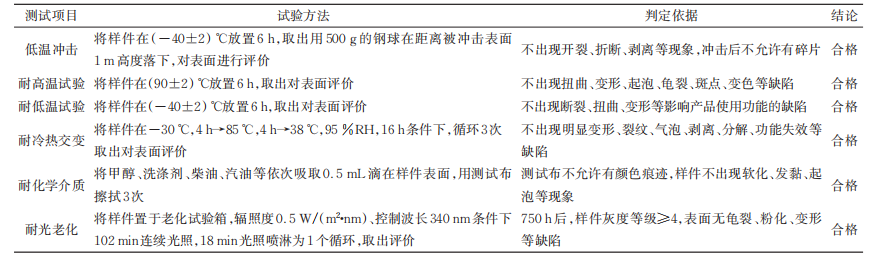

Prepare the duct support sample using the above materials and, and conduct low-temperature impact, high-temperature resistance, low-temperature resistance, thermal cycling, chemical resistance, and light aging tests. The test results show that all meet the design requirements, as shown in Table 2.

Table 2 Performance Test Results of Fairing Bracket Parts

2.7 Vehicle Performance Analysis

Install two fairing bracket samples symmetrically on a certain heavy-duty truck model, with one end fixed to the cab body using two M8 bolts, and the other end fixed to the fairing using two M8 bolts, as shown in Figure 7.

Figure 7 Fairing Bracket Sample Installed

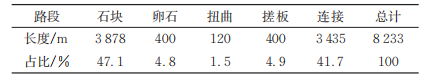

The vehicle was loaded to the design requirement load of 49,000 kg and underwent a comprehensive road durability test at the Xiangyang Test Site. The test process included sections with stones, pebbles, twist roads, washboard roads, and connecting roads, with each road surface length and proportion shown in Table 3. The vehicle entered the comprehensive road via the connecting road, traveling at 50 km/h, and applied brakes to decelerate to 20 km/h when approaching the pebble road, passing through the pebble road at a constant speed. It accelerated to 40 km/h, and when approaching the twist road, it braked to decelerate to 10 km/h, passing through the twist road at 8~10 km/h. It accelerated to enter the angled washboard road at an initial speed of 50~60 km/h, accelerated through, and then entered the misaligned washboard road at an initial speed of 60~70 km/h, coasting through. When approaching the pebble road again, it braked to decelerate to 20 km/h and passed through the pebble road at 20 km/h, accelerating to 40 km/h. When approaching the twist road again, it braked to decelerate to 10 km/h, passing through the twist road at 8~10 km/h again, and then entered the stone road, taking bends at 20 km/h and straights at 25 km/h. This constitutes one cycle. After undergoing a 7,500 km comprehensive road test verification, the results showed that the appearance of the fairing bracket was good, with no obvious defects, and it could meet the service life requirements.

Table 3 Length and Proportion of Each Section

03 Conclusion

As the content of recycled polycaprolactam (PCR-PA6) increases, the overall performance of 30% glass fiber reinforced polycaprolactam-based composites (PA6-GF30) shows a downward trend. Relatively speaking, the material performance changes are minor when the proportion of PCR-PA6 does not exceed 20%. From the perspective of material performance, the decreases in tensile strength, elongation at break, flexural strength, and impact strength are more pronounced, while the decreases in tensile modulus, flexural modulus, melting point, and heat deformation temperature are less significant.

Select the PA6-GF30 material containing 20% PCR-PA6 to prepare the duct cover support sample. After testing the components and the complete vehicle, it meets the performance requirements. This indicates the feasibility of using modified PCR-PA6 in automotive parts, providing application scenarios and references for the recycling of PA6.

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

EVA Morning Prices on September 12: Most of the Market Holds Steady, Highest Rise of 50 Yuan

-

[PET Weekly Outlook] Polyester Bottle Chips Expected to Oscillate and Warm Up with Costs Today

-

Top Ten Personnel Changes in the Auto Industry: Insights into Industry Anxiety and Progress | Vision 2025

-

Domo Chemicals Files for Bankruptcy Protection in Germany! B. Braun Launches New Supply Assurance Program

-

List Released! Mexico Announces 50% Tariff On 1,371 China Product Categories