Interstuhl Uses Dürr Products for Seat Surface Coating

February 5, ZP Vision News, Europe's leading seat manufacturerInterstuhl Büromöbel GmbH & Co. KGDürr's modern painting technology is utilized in the production of their industrial and laboratory chairs. The new system enables automated coating of the inner surfaces of the foaming molds. With the help of Dürr's modular...EcoSupply2 CorePaint supply system, and byEcoAUCControlled Two-Component2K) process, InterstuhlSuccessfully developed a highly efficient painting process that supports up to five colors.

Headquartered in Metzingen, Germany, Meßstetten Interstuhl Büromöbel GmbH & Co. KG(hereinafter referred to as“Interstuhl”( ) is one of Europe's leading seating manufacturers, with over sixty years of dedicated research and development in high-quality office chairs. The company has now introduced Dürr's innovative spray technology to its production line for industrial and laboratory chairs. By adopting Dürr'sEcoGun AS AUTO proSpray guns can precisely coat the inner walls of foaming molds. When liquid polyurethane (PUAfter the foam is injected into the mold, it naturally absorbs the coating and displays the corresponding color, achieving one-step molding and coloring.

“The paint used by the client is of a special nature.——It is a multi-functional material.”杜尔欧洲一般工业销售团队负责人Fabian SchiltExplain that,“It not only gives the product color but also provides the necessary electrical conductivity. As these office chairs will be used in cleanrooms, electrostatic discharge (ESD) protectionESDIn areas such as ( ) and other special environments, preventing electrostatic discharge is of utmost importance.”

EcoSupply2 CoreCompact coating supply system

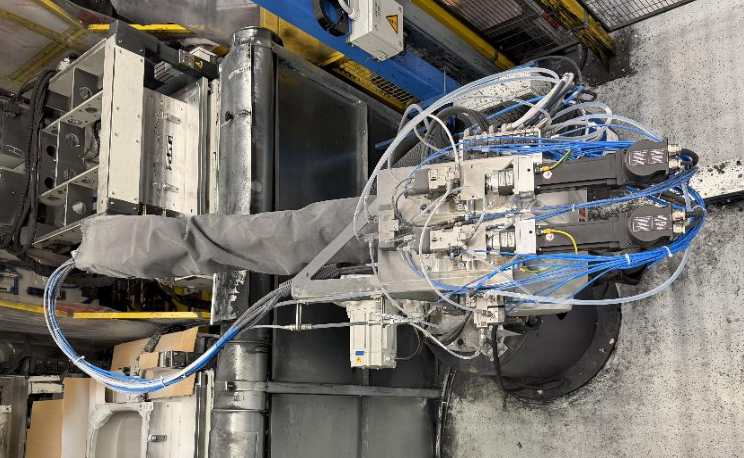

2025 9Yue, Dur is a polyurethane equipment expertHenneckeProvide technical support to successfully integrate this painting equipment intoInterstuhlLocated in Meßstetten -Tübingen Meßstetten-Tieringen) in the existing robot system of the production base. The complete system includes a mountedEcoGun AS AUTO proSpray painting robot, six setsEcoSupply2 CorePaint supply system, and a set of... EcoAUC 2KControl unit. Currently,InterstuhlThe production line has implemented the system to process three colors, while its design capacity can support coating operations for up to five colors.。

EcoSupply2 CoreThe coating supply system is designed to be compact and user-friendly, making it particularly suitable for use in industrial spraying scenarios with limited space. InterstuhlThe factory, the system is also equipped withEcoPump9Precision gear pump2KMixing and color changing modules. These components are very popular with... InterstuhlThe primary reason for its favor is its ability to effectively handle the special properties of the paint used, which is not only difficult to rinse off and cures quickly but also easily causes valve blockage.。

Ready for practical use.

in Ledeč nad Sázavou in the Czech RepublicLedeč nad SázavouA series of rigorous tests conducted at the Dürr Test Center in ( ) have demonstrated that Dürr color change valves feature a dead-space-free design.——Materials leave no residue, ensuring reliable and clean processing. FromInterstuhl Andreas KunstTranslate the above content into English, output the translation directly, without any explanation.“From the initial paint application technology demonstration onwards, Dürr has thoroughly convinced us. Their technical team has consistently provided us with strong support, and with their extensive expertise and high level of dedication, they successfully drove the entire project to fruition. ”

Currently, EcoSupply2 CoreAvailable in the Chinese market. Scan the QR code below for detailed information. Dürr China General Industry Team is ready to help you achieve efficient and reliable surface treatment with our professional experience. Meanwhile, we are recruiting partners and agents for the general industrial market. If you are interested in expanding related business, please feel free to contact us.

1:EcoSupply2 Core Compact paint supply system, space-saving.

2: two-component ( 2KRobotic systems for metrology.

3:Interstuhl Büromöbel GmbH & Co. KG Dürr's advanced coating technology is applied in the production of its industrial and laboratory chairs.

About Dürr

Dürr Systems Engineering (Shanghai) Co., Ltd. is a wholly-owned subsidiary of the Dürr Group established in China, sinceSince its establishment in 1995, the company has consistently focused on the planning and construction of paint shops and assembly lines. Dürr China's campus, located in Qingpu District, Shanghai, is equipped with advanced testing facilities for pretreatment, electrocoating, painting, sealing, and gluing, allowing it to provide comprehensive product validation and testing services to customers. Adjacent production workshops are equipped with modern manufacturing and processing equipment, specializing in the production and integration of process equipment. Dürr China has established a nationwide service network, deeply integrated into the local industrial ecosystem, and continuously provides efficient and professional services to its customers. Leveraging its localized technological accumulation and resource advantages, the company not only oversees business operations in the Southeast Asian market but also actively promotes technical solutions developed in China to a global audience. As of 2024 ,The total number of Dürr employees in China is approximately1,300

Dürr Group is a world-leading enterprise in the field of mechanical and plant engineering.,Specialized in automation, digitalization, and energy efficiency technologies. The group provides efficient and sustainable manufacturing processes with its products, systems, and services for industries such as automotive manufacturing, furniture and timber construction, medical and electronics assembly, and battery production. 2024In [year], Duer Group achieved sales of [amount].47billion euros, globally32countries with approximately 18,000employees and130business locations. Since2025 10Following the sale of the Environmental Technology Business Unit at the end of the month, the group's operations will be restructured into three major business units.

- Automotive Division Painting technology, general assembly, testing and filling technology, and battery electrode coating system

- Industrial Automation Division: Assembly and testing systems for automotive parts, medical devices, and consumer goods, as well as dynamic balancing technology solutions and battery electrode coating systems.

- Woodworking Division: Woodworking Machinery

【Copyright and Disclaimer】The above information is collected and organized by PlastMatch. The copyright belongs to the original author. This article is reprinted for the purpose of providing more information, and it does not imply that PlastMatch endorses the views expressed in the article or guarantees its accuracy. If there are any errors in the source attribution or if your legitimate rights have been infringed, please contact us, and we will promptly correct or remove the content. If other media, websites, or individuals use the aforementioned content, they must clearly indicate the original source and origin of the work and assume legal responsibility on their own.

Most Popular

-

Key Players: The 10 Most Critical Publicly Listed Companies in Solid-State Battery Raw Materials

-

Vioneo Abandons €1.5 Billion Antwerp Project, First Commercial Green Polyolefin Plant Relocates to China

-

Clariant's CATOFIN™ Catalyst and CLARITY™ Platform Drive Dual-Engine Performance

-

Multifaceted Collaboration: PA Prices Rebound Against Trend to Break Through

-

Dow suffers poor performance, announces major layoffs of 4,500 employees