Sunlight panels adopt a unique U-shaped locking design that facilitates convenient installation. They combine excellent light transmission, thermal insulation, and high strength, providing a lightweight solution with no thermal expansion issues and a leak-proof design. They can withstand very high loads and are ideal for curved designs, resulting in low structural costs. These features characterize the star-shaped five-layer structure U-shaped locking sunlight panels. Additionally, the U-shaped connection structure and free-floating design can meet designers' needs for greater freedom and creativity, allowing them to break free from material limitations and create more aesthetically pleasing and environmentally friendly design solutions. Besides the star-shaped five-layer structure U-shaped panels, the company can also produce rectangular two-layer U-shaped locking sunlight panels, rectangular four-layer U-shaped locking sunlight panels, and rectangular six-layer U-shaped locking sunlight panels PC sunlight panels.

PC sunlight panels are mainly used in municipal construction, home decoration, and commercial applications. The panels are impact-resistant, lightweight, easy to install, aging-resistant, and UV-resistant. They are environmentally friendly, aesthetically pleasing, and easy to process.

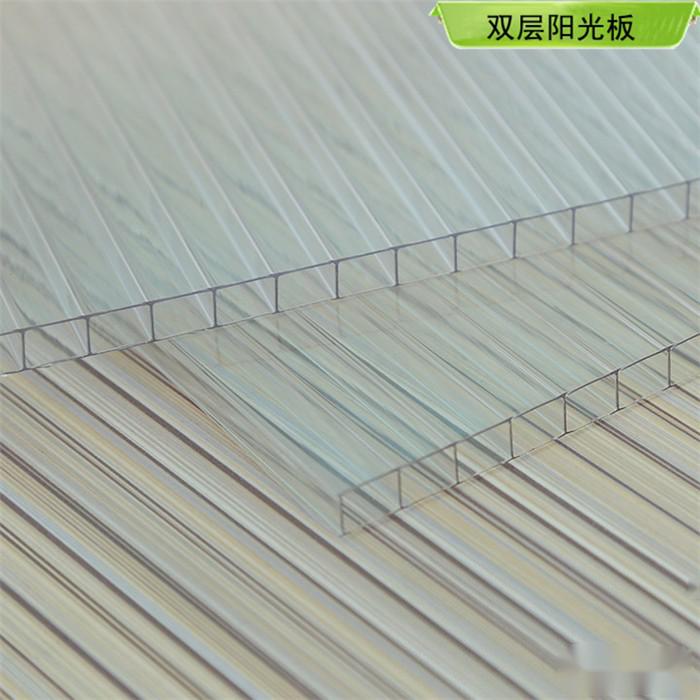

PC double-layer sunlight panels features

1, Light transmission: PC panels have a light transmission rate of up to 89%, comparable to glass in beauty. UV coated panels will not yellow, fog, or reduce light transmission quality when exposed to sunlight, with only a 6% loss of light transmission after ten years, while PVC loss rates can be as high as 15%—20% and fiberglass is 12%-20%.

2, Impact resistance: The impact strength is 250-300 times that of ordinary glass, 30 times that of acrylic panels of the same thickness, and 2-20 times that of tempered glass. It shows no cracks when a 3kg hammer is dropped from two meters.

3, UV resistance: PC panels have one side coated with UV-resistant (UV) coating, and the other side has anti-condensation treatment, combining UV resistance and thermal insulation properties. They can block UV rays, making them suitable for protecting valuable artworks and exhibits from UV damage.

4, Lightweight: With a specific gravity only half that of glass, they save on transportation, handling, installation, and supporting frame costs.

5, Fire resistance: National standard GB50222—95 confirms that PC panels are classified as flame-retardant grade B1. The ignition point of PC panels is 580℃, and they self-extinguish after the flame is removed, producing no toxic gases while burning and not promoting the spread of flames.

6, Flexibility: They can be cold-bent on-site according to design drawings to create arched, semi-circular roofs and windows. The minimum bending radius is 175 times the thickness of the panel; they can also be heat-bent.

7, Sound insulation: PC panels have significant sound insulation effects, providing better acoustic insulation than glass and acrylic panels of the same thickness. Under the same thickness conditions, PC panels improve sound insulation by 3—4DB compared to glass. They are internationally recognized as materials for highway sound barriers.

8, Energy efficiency: PC panels keep cool in summer and retain heat in winter. They have a lower thermal conductivity (K value) than ordinary glass and other plastics, with insulation effects 7%—25% higher than that of equivalent glass. The insulation efficiency of PC panels reaches 49%, significantly reducing heat loss, making them suitable for buildings with heating systems, and they are environmentally friendly materials.

9, Temperature adaptability: PC panels do not become brittle at -100℃ and do not soften at 135℃. Their mechanical properties remain stable even in harsh environments.

10, Weather resistance: PC panels maintain the stability of all physical indicators within the temperature range of -40℃ to 120℃. After 4000 hours of artificial climate aging tests, the yellowing degree is 2, and the light transmission reduction is only 0.6%.

11, Anti-condensation: When the outdoor temperature is 0℃ and the indoor temperature is 23℃, with indoor relative humidity below 80%, the inner surface of the material does not condense.

Application range of sunlight panel products

1, Lighting roofs for office buildings, department stores, hotels, villas, schools, sports venues, entertainment centers, and public facilities.

2, Sound barriers for highways, subways, and urban elevated roads.

3, Roofs for agricultural greenhouses, flower greenhouses, and indoor swimming pools.

4, Awnings for subway entrances, bus stations, parking lots, shopping malls, pavilions, lounges, corridors, etc.

5, Anti-theft counters for banks and jewelry stores.

6, Advertising light boxes, bus stop panels, advertising display boards.

7, Indoor partitions, pedestrian passages, guardrails, balconies, shower rooms in offices and homes.

Products

1, The company's main products include: PS panels, PC sunlight panels, PC solid panels, PC weather-resistant lighting covers, PC sheets, PC corrugated sheets, and PC engineering-specific accessories. It is currently one of the largest, most market-share-holding, and comprehensive manufacturers of PC panels in mainland China, with products sold to 30 provinces, municipalities, and autonomous regions nationwide, and exported to countries in Asia, Africa, Europe, and America.

2, Products are made using German Bayer PC raw materials, with all indicators tested by the National Chemical Building Materials Testing Center meeting industry standards. They feature excellent weather resistance, impact resistance, high light transmission, and strong plasticity, with characteristics such as thermal insulation, sound insulation, lightweight, fire resistance, and UV protection. They are widely used in public and civil construction for lighting roofs, shading (rain) awnings, sound barriers, various greenhouses, road signs, advertising light boxes, phone booths, waiting (airplane) booths, home balconies, etc., making them an ideal lighting shelter material highly regarded and favored by the modern architectural decoration industry.

3, All products are supplied directly by the manufacturer, reducing intermediaries, and saving procurement costs for customers.

Convenient logistics services

The company has signed freight contracts with multiple express and logistics companies, purchased transportation insurance, and signed damage compensation agreements to ensure timely delivery of goods to customers and ensure the safety of products.

Thoughtful after-sales service

After the products leave the factory, we will track them promptly and provide customers with shipping numbers and logistics company contact information for timely pickup. Customers are requested to check the products upon receipt; if any damage is found, please communicate directly with the logistics company and promptly report the actual situation to our company!

For more information, please visit:

| http://www.zjkpcban.com |