Zhangjiakou Polycarbonate Sheet is quoted at a price per square meter. The size of a whole sheet is 2.1 meters by 6 meters. For small quantities, the sheet needs to be cut; for large quantities, it can be delivered as a whole sheet. The available colors in stock are transparent and lake blue, while other colors and special sizes can be customized. For details, please consult online customer service or contact us by phone at 13011905700.

Specifications

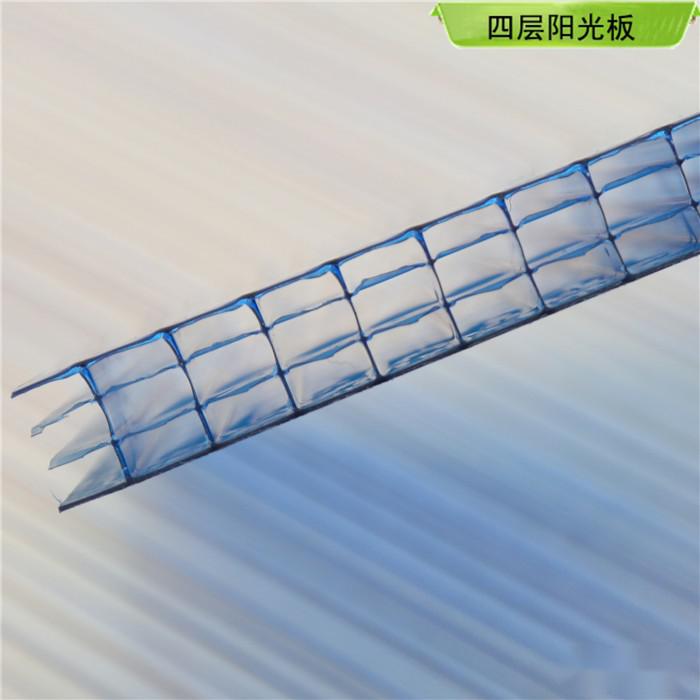

The commonly seen polycarbonate sheets are 4mm, 6mm, 8mm, and 10mm thick; these thicknesses usually have a double-layer structure.

Thicker sheets typically exhibit a multi-layer and irregular structure.

Product Features

PC polycarbonate sheets are produced mainly from polycarbonate as the raw material. Polycarbonate sheets rapidly entered the construction decoration material market in the mid-1980s. They offer excellent properties such as lightweight, weather resistance, flame retardance, and sound insulation, surpassing laminated glass, wire glass, tempered glass, and hollow glass. Due to the unique high quality of polycarbonate sheets, they have gained widespread recognition in architectural design, decoration engineering, environmental engineering, and the advertising industry. According to statistics, since the late 1980s, the sales volume of polycarbonate sheets in the international market has increased by 20% annually. Since 2008, total annual sales have exceeded 1 billion square meters. In the event of natural disasters such as hail or heavy snow, their ability to withstand natural calamities is poor, resulting in severe damage to greenhouses and significant losses to crops grown inside. The use of film afterward also causes white pollution. The double-layer and multi-layer polycarbonate sheets, which emerged in Europe in the 1970s, are considered the fourth generation of greenhouse covering materials and have been widely applied in agricultural greenhouse construction. Their characteristics include:

1. Lightweight: its weight is one-twelfth that of the same thickness of glass;

2. Impact resistance: impact strength is 300 times that of ordinary glass, 30 times that of acrylic sheets, and twice that of tempered glass;

3. Energy-saving: low thermal conductivity (K value) and good thermal insulation, energy savings are 1.5-1.7 times that of glass of the same thickness;

4. Weather resistance: artificial climate aging test for 4000 hours, yellowing degree of 2, light transmittance reduction of only 0.6%;

5. Wide application range: stable physical properties between -40℃ and 120℃, no deformation of the polycarbonate sheet;

6. Cold bending: can be cold bent, the safe bending radius is more than 175 times its thickness;

7. Fire resistance: tested by the National Fire Building Materials Quality Supervision and Inspection Center, the burning performance of the polycarbonate sheets produced by our company reaches the difficult-to-burn B1 level;

8. Anti-condensation: one side can be treated for anti-condensation to prevent condensation water from dripping;

9. Sound insulation: polycarbonate sheets have good sound insulation properties, effectively reducing noise;

10. Light transmission: light transmittance can reach up to 88%;

11. UV layer: UV protection coating is added to the surface of the sheet to extend its lifespan;

12. Wind resistance: wind resistance performance reaches the national standard GB/T7106-86 level.

Product Applications

1. Unique decoration and resting pavilions in parks and amusement places;

2. Interior and exterior decoration of commercial buildings, curtain walls of modern urban buildings;

3. Agricultural greenhouses and breeding greenhouses;

4. Modern ecological restaurant roofs in greenhouse structures;

5. Bicycle sheds, balcony sunshades, and roof resting pavilions in all units or communities;

6. Skylights in office buildings, department stores, hotels, villas, schools, hospitals, sports venues, entertainment centers, and public facilities.

For more information about Zhangjiakou Polycarbonate Sheet, please visit:

| http://www.zjkpcban.com |