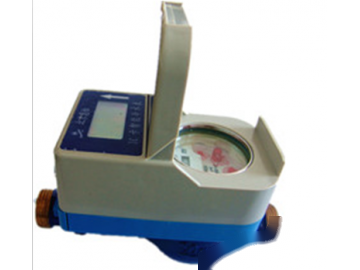

Performance characteristics of Yanjiao household card-insertion water meter

1. Improved anti-freezing performance of IC card water meters: The shells of similar water meters are made of cast lead and copper materials using casting processes (which have lower material costs), making it difficult to detect casting defects such as loose metallographic structure, pores, slag inclusion, small cracks, and internal stress. They use chemical methods for sealing to compensate for casting defects; our company's IC card water meter shell is made of forged copper alloy (which has high requirements for the percentage of chemical element content in metals) produced using hot extrusion processes (which have higher material costs), resulting in a tightly structured metallographic organization with no pores, slag inclusion, small cracks, or internal stress, significantly improving overall mechanical performance, free from lead elements, and no need for chemical sealing methods, making it more compliant with safety and hygiene requirements. The digital display parts of similar water meter mechanisms use tempered glass, which is fragile and can lead to significant water leakage; our company's water meter mechanism uses high-strength PC plastic for the outer cover of the mechanism, employing a dry structure design that is not affected by water quality, ensuring clear digital display. The mechanism does not come into contact with tap water, making it less prone to damage and freezing, thereby preventing significant water leakage.

2. Enhanced waterproof and moisture-proof performance of IC card water meters: The waterproof and moisture-proof performance directly affects the battery lifespan and the effectiveness of electronic control parts in IC card water meters. All electrical components are sealed with glue, and the actuator (motor) uses 704 sealant; the battery uses customized waterproof batteries, while the card-swiping coil and circuit board (including the LCD screen) are fixed with hot melt adhesive, 3200, and screw adhesive, then placed in a waterproof box (with waterproof and moisture-proof silicone sealing rings); the base meter's signal transmission device is sealed with electrical sealing glue; the connection points of the base meter use 704 sealing. Finished products are subjected to waterproof and moisture-proof tests three times, each time involving 10 IC card water meters, submerged in water for 90 days, and then taken out for functional testing, with the tested IC card water meters operating normally.