1. There are many types of plastic tanks, including: rotational molded tanks, fiberglass tanks, ceramic tanks, rubber tanks, and welded plastic tanks. In terms of cost performance, rotational molded tanks are currently superior. Rotational molded tanks can be further divided into steel-lined plastic tanks and all-plastic tanks, which include various types such as vertical, horizontal, transport, and mixing tanks. The processing technology for tanks: The processing technology for polyethylene tanks: they are made from polyethylene (linear low-density polyethylene LLDPE, high-density polyethylene HDPE) as raw materials, and are formed in one go using rotational molding techniques.

2. Characteristics of polyethylene tanks:

The foreign abbreviation for polyethylene is PE. The application temperature for low-density polyethylene is 60°C, and for high-density polyethylene, it is 70°C. The application temperature can range down to -40°C. They have advantages such as no welding seams, no leakage, non-toxic, aging resistance, impact resistance, corrosion resistance, long service life, and compliance with hygiene standards. They compensate for the disadvantages of all-plastic rotational molded tanks, which have poor rigidity, are not pressure-resistant, and are sensitive to temperature differences. The inner lining of the products is flat, smooth, and sturdy. Compared to traditional steel-lined plastic tanks, steel-lined rubber tanks, and steel-lined fiberglass tanks, they offer better corrosion resistance, no leakage, no delamination, wear resistance, can withstand certain pressures, can tolerate higher temperatures, and have a longer lifespan. Their price is lower than that of traditional tanks of the same specifications, making them ideal containers for storing corrosive liquids. Therefore, they are an extremely excellent type of corrosion-resistant tank.

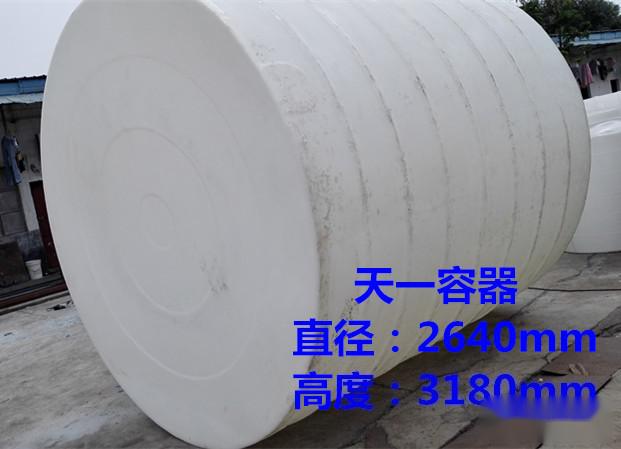

3. PE tanks, plastic tanks, plastic water towers, pure water tanks, etc. The products are produced using imported PE raw materials and rotational molding technology, strictly adhering to quality standards. They feature excellent comprehensive mechanical and physical properties, rich underlying mechanical principles, no seams, one-time molding, acid and alkali resistance, impact resistance, high-temperature resistance (up to 80°C), freeze resistance (down to -30°C), smooth inner and outer surfaces, acid and alkali resistance, strong earthquake resistance, UV resistance, long service life, easy cleaning without algae growth, and convenient installation and mobility. They are used in high-rise buildings for secondary water supply, water storage, water treatment and purification equipment, industrial cooling water, chemical formulations, chemical raw materials, storage and transportation of various oils, beverages, and alcoholic beverages, making them ideal water storage containers for urban, agricultural, and rural rooftop water storage, hotels, and inns, with the advantages of safety, convenience, and no maintenance, making them an ideal type of plastic container. The product models range from 500L to 50 tons, with a complete range of models. Other products from the company, including dosing tanks, salt solution tanks, PE food round barrels, PE square barrels, turnover boxes, and traffic facilities, have all received consistent praise from consumers. Each product comes with two free connectors with a diameter of 50 and below, and free installation of connectors.

4. Main products: Nanning Tianyi's main products include: PE tanks, plastic tanks, chemical tanks, anti-corrosion tanks, plastic water towers, conical bottom barrels, plastic round barrels, plastic square boxes, dosing tanks, float tanks, crash barrels, water barriers, acid washing tank processing, steel-lined plastic products, plastic containers, plastic special-shaped parts welding, transport tank welding, fiberglass waste gas treatment equipment, and large fiberglass containers, as well as undertaking various special-shaped parts processing.