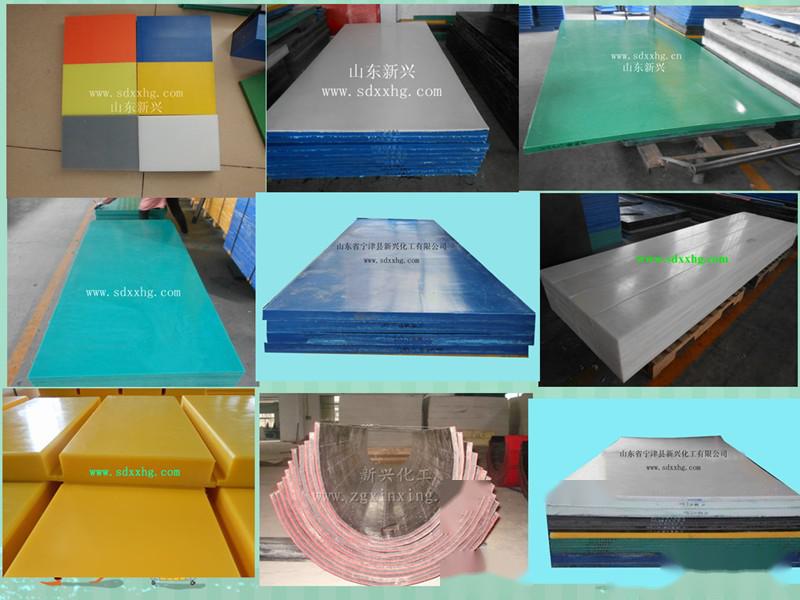

Where to find high-quality high molecular polyethylene sliding boards polyethylene sliding boards wear-resistant sliding boards——Shandong Ningjin Xinxing Chemical Co., Ltd.

The largest production base for engineering plastics in the country, a manufacturer of ultra-high molecular weight polyethylene boards, striving to be among the top 500 enterprises producing ultra-high molecular weight polyethylene boards!

If you want to learn more about the detailed information of ultra-high molecular weight polyethylene boards, feel free to call us at: 0534-5223277 13173333540. Company website: www.sdxxhg.net www.sdxxhg.com. Xinxing Chemical's Zhang Longzhen is sincerely at your service!

1. The wear resistance of ultra-high molecular weight polyethylene boards is the best among plastics, and the larger the molecular weight, the higher the wear resistance and impact resistance of the material;

2. The impact strength of ultra-high molecular weight polyethylene boards is high among existing plastics, and it still maintains considerable impact strength even at 70°C;

3. Self-lubricating, low friction coefficient, energy-saving, with a wax-like feel.

4. Extremely low water absorption. Therefore, its physical and mechanical properties are independent of the humidity factors in the working conditions used.

5. Ultra-high molecular weight polyethylene boards are chemically stable and can resist various corrosive media and organic solvents such as acids, alkalis, and salts within a certain temperature and concentration range.

6. Ultra-high molecular weight polyethylene boards are tasteless, non-toxic, odorless, inherently non-corrosive, and have physiological cyclicity and adaptability.

7. Non-adhesive;

8. When the molecular weight of high-density polyethylene exceeds 500,000, the embrittlement temperature drops to 140°C. Ultra-high molecular weight polyethylene can even be used at temperatures below -269°C under the action of liquid nitrogen, still maintaining certain mechanical strength.

Ultra-high molecular weight polyethylene boards are a type of thermoplastic special engineering plastic. It combines the superior properties of all plastic materials and is of high value among existing engineering plastics. With the development of technology in the plastic processing industry, the application fields of ultra-high molecular weight polyethylene will continue to expand.

1. Liners: coal bin liners, hoppers, chutes, wear-resistant plates, supports, sliding surfaces, rollers, etc.;

2. Food machinery: guide rails, star wheels, guide gears, rollers, bearing bushings, etc.;

3. Papermaking machinery: water absorption tank covers, guide plates, doctor blades, water wings;

4. Chemical industry: sealing filler plates, filling materials, vacuum molds, pump components, bearing bushings, gears, sealing joints;

5. Assembly line machinery: turntables, guide rails, wear-resistant strips, curved guide rails, magnetic bends, chain guide rails, gears;

6. Others: agricultural machinery, ship parts, electroplating industry, ultra-low temperature machinery components, etc.

7. Large cranes and heavy machinery: placed under the legs of large cranes for support.

8. Used as fender boards, collision plates, and buffer plates at ports and docks to prevent collisions between ships and docks.

The professional advantages of Shandong Xinxing:

1. A large number of molds with complete specifications, developed and designed by the company's technical department.

2. A long production history, established in 1999, with strong technical strength and a professional production and sales team.

3. Advanced and complete machinery and equipment, with processing production equipment and an independent laboratory in the industry.

4. Product diversity: widely used in industries such as electricity, ports, docks, coking, coal, papermaking, textile, chemical, and environmental protection.

5. Products are sold to domestic and foreign markets, covering various regions. Your satisfaction is our pursuit!!!