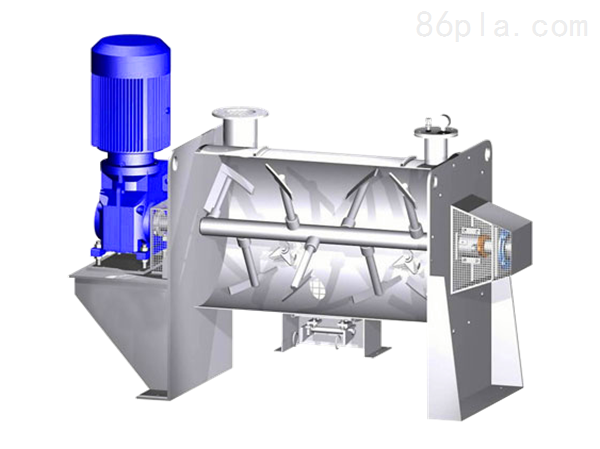

Brief Description:A vertical mixer mainly consists of: motor wheel, motor, barrel, screw, discharge port, cleaning port, pulley, observation window, ladder, inlet, electrical box, circulating drop port, and feeding port.

Vertical mixing blenderPrinciple:

The machine rapidly rotates the screw to lift the raw material from the bottom of the barrel to the top, then scatters it in a umbrella-like pattern, allowing it to fall back to the bottom. This causes the material to tumble and mix within the barrel, achieving uniform mixing of a large quantity of raw material in a short time. It performs simple blending and homogenization of the material and can also be assisted by hot air for simple drying and dehumidification.

Main Structure:

1. Frame Section: All working components of the machine are installed and fixed on the frame. The frame of this machine is made by welding high-quality carbon steel plates and channel steels, and it has passed strict product qualification certification and specific process requirements to meet the purpose for which the machine is used.

2. Transmission Connection Section: This machine uses a cycloidal pinwheel reducer to drive the main shaft for rotation. The working parts of the host all use nylon cylindrical pins as the transmission connectors, which are easy to assemble and maintain.

3. Mixing working section: The power is transmitted from the drive wheel to the main shaft via a pin coupling. This causes the material to be evenly turned over within the mixing chamber, ensuring thorough blending and significantly reducing the amount of residual material.

Vertical mixer blenderMaintenance

After each shift, the equipment, both inside and out, as well as the surrounding area, must be cleaned.

2. Inspect the mixer's rotation condition (balance and friction) of the equipment every month.

3. The machine should be placed in a well-ventilated area to ensure that the heat generated by the electric motor can dissipate, thereby prolonging the life of the motor.

4. Regularly check if the belt is loose, and adjust the motor outward until the belt is tightened.

5. Periodically grease the bearings to ensure lubrication between them.

6. If any malfunction is detected during the operation of the machine, it must be stopped and the power source disconnected before handling.

7. Before the machine starts, check if the screws of the blades inside the barrel are loose, and if so, tighten them.

8. Do not mix tools, hard objects, or strip-like materials into the barrel.

Modified Plastic Producers

Engineering Plastic Producers

Biodegradable Plastic Producers

Others

Others