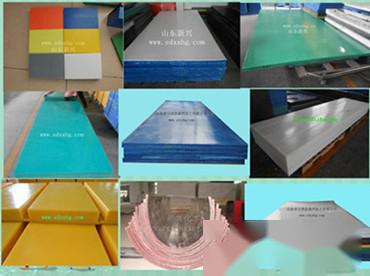

Various Specifications and Thicknesses of Ultra High Molecular Weight Polyethylene Sheets High Molecular Polyethylene Wear-resistant SheetsVarious Specifications and Thicknesses of Ultra High Molecular Weight Polyethylene Sheets High Molecular Polyethylene Wear-resistant Sheets

If you feel that this product introduction is not detailed enough, please call us for consultation. We sincerely look forward to your call…

Shandong Ningjin Xinxing Chemical Co., Ltd. Mold Sizes:

3000X1500X(10-300)MM

4700X1200X(10-300)MM

5000X1300X(10-300)MM

4500X2000X(10-300)MM -2000X1000X(10-300)MM

3050X1220X(6-100)MM

Let’s first understand the specific characteristics of ultra high molecular weight polyethylene sheets:What are they:

Let’s first understand the specific characteristics of ultra high molecular weight polyethylene sheets:What are they:

1. The wear resistance of ultra high molecular weight polyethylene sheets ranks first among plastics, and the larger the molecular weight, the higher the wear resistance and impact resistance of the material;

2. The impact strength of ultra high molecular weight polyethylene sheets is a high value among existing plastics, and it still has considerable impact strength even at 70℃;

3. Self-lubricating, low friction coefficient, energy-saving, with a wax-like feel.

4. Extremely low water absorption. Therefore, its physical and mechanical properties are not related to the humidity factors in the working conditions.

5. Ultra high molecular weight polyethylene sheets are chemically stable, being able to resist various corrosive media and organic solvents such as acid, alkali, and salt within a certain temperature and concentration range.

6. Ultra high molecular weight polyethylene sheets are odorless, non-toxic, and non-corrosive, with physiological recyclability and adaptability.

7. Non-adhesive;

8. When the molecular weight of high-density polyethylene exceeds 500,000, the embrittlement temperature drops to 140℃. Ultra high molecular weight polyethylene can even function at temperatures below -269℃ under liquid nitrogen, still maintaining certain mechanical strength.

With so many excellent properties, the application fields of ultra high molecular weight polyethylene sheets are also very extensive. Let’s introduce its specific applications in various industries:

With so many excellent properties, the application fields of ultra high molecular weight polyethylene sheets are also very extensive. Let’s introduce its specific applications in various industries:

1. Linings: Coal bunker liners, hoppers, chutes, wear plates, supports, and sliding surfaces, rollers, etc.;

2. Food machinery: Guide rails, star wheels, guide gears, rollers, bearing liners, etc.;

3. Papermaking machinery: Water suction tank covers, flow guides, water scraping plates, water wings;

4. Chemical industry: Seal filling plates, filling materials, vacuum mold boxes, pump components, bearing liners, gears, sealing joints;

5. Assembly line machinery: Turntables, guide rails, wear-resistant strips, curved guide rails, magnetic bends, chain guide rails, gears;

6. Others: Agricultural machinery, ship parts, electroplating industry, extremely low-temperature machine components, etc.

7. Large cranes and machinery: Placed under the legs of large cranes to provide support.

8. Used as dock fender boards, anti-collision boards, and buffer boards to prevent collisions between ships and docks.

Shandong Ningjin Xinxing Chemical Co., Ltd. is the largest production base for engineering plastics (ultra high molecular weight polyethylene sheets) in the country, striving to be among the top 500 ultra high molecular weight polyethylene sheet manufacturers! We welcome you to visit our company for guidance and inspection. Phone: 0534-5223277 13173333540 Online QQ: 2875013107 Xinxing Chemical Zhang Longzheng sincerely serves you!!

Can be processed and produced according to your dimensions.

As long as you provide the drawings, we can process and produce for you.

Color: Multi-color processing available.

Specifications: Customized processing according to customer requirements.

Packaging: Waterproof pallet.

Shandong Xinxing sincerely looks forward to cooperating with you!