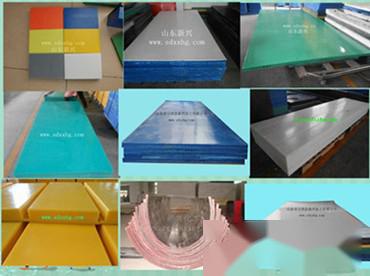

Ultra High Molecular Weight Polyethylene Plate Manufacturer

The largest production base for ultra high molecular weight polyethylene plates in the country, a leading manufacturer of polymer polyethylene plates, Shandong Ningjin Xinxing Chemical Co., Ltd. is committed to serving you as it strides towards the Fortune 500! Feel free to call us for inquiries: 0534-5223277 13173333540 Online QQ: 2875013107

Excellent Characteristics of Ultra High Molecular Weight Polyethylene Plates:

1. Ultra high molecular weight polyethylene plates have the best wear resistance among plastics, and the higher the molecular weight, the greater the wear resistance and impact resistance of the material;

2. The impact strength of ultra high molecular weight polyethylene plates is among the highest values in existing plastics, retaining considerable impact strength even at 70℃;

3. Self-lubricating, low friction coefficient, energy-saving, with a wax-like feel.

4. Extremely low water absorption. Therefore, its physical and mechanical properties are unaffected by humidity factors in working conditions.

5. Ultra high molecular weight polyethylene plates are chemically stable, resistant to acids, bases, salts, and various corrosive media and organic solvents within certain temperature and concentration ranges.

6. Ultra high molecular weight polyethylene plates are odorless, non-toxic, and have no corrosive properties, exhibiting physiological cyclicity and physiological adaptability.

7. Non-adhesive;

8. When the molecular weight of high-density polyethylene exceeds 500,000, the embrittlement temperature drops to 140℃. Ultra high molecular weight polyethylene can even maintain certain mechanical strength at temperatures as low as -269℃ under liquid nitrogen.

Ultra high molecular weight polyethylene plate is a thermoplastic special engineering plastic. It combines the superior properties of all plastic materials and is among the highest values in existing engineering plastics. As the technology in the plastic processing industry develops, the application field of ultra high molecular weight polyethylene will continue to broaden.

Now let’s introduce the practical applications of ultra high molecular weight polyethylene plates in various industries:

Now let’s introduce the practical applications of ultra high molecular weight polyethylene plates in various industries:1. Papermaking Industry: Vacuum box panels, dehydration plates, scrapers, sealing strips, paper cutter sleeves, etc.

2. Beverage and Food Machinery: Utilizing wear resistance, impact resistance, non-adhesion, and hygienic non-toxicity to produce work tables, conveyors, gears, etc.

3. Water Treatment: Sludge scrapers in sewage treatment plants, spiral conveyor liners, slurry pump impellers, pump shaft sleeves, gears for clarification devices, and sedimentation tank liners.

4. Textile Machinery: Utilizing impact resistance, wear resistance, and self-lubrication for components such as 36 gears, shuttle frame machine buffer baffles, bearing liners, etc.

5. Medical Devices: Human implants, artificial joints, orthopedic instruments, and brackets, surgical instruments.

6. Automotive Manufacturing: Products made from ultra high molecular weight polyethylene not only reduce the number of parts but also effectively reduce noise. Manufacturers should utilize the molding characteristics of ultra high molecular weight polyethylene products to integrate multiple parts, reducing quantity and aiming to achieve complex parts in a single molding process. The usage of ultra high molecular weight polyethylene in automobiles is showing an upward trend annually.

7. Due to its extremely low friction coefficient, high impact strength, low water absorption, excellent self-lubrication, and outstanding corrosion resistance, it can be used in coal bins, storage bins, mixed material chutes, and dump truck liners.

8. Transport Machinery: Guide rails, conveyor belts, sliding seats for conveying devices, fixed plates, timing star wheels for production lines.

9. Food Machinery: Star wheels, bottle-counting screws, filling machine bearings, bottle-grabbing machine parts, gaskets, guide pins, cylinders, gears, roller chain handles.

10. Papermaking Machinery: Water absorption tank covers, guide wheels, scrapers, bearings, nozzles, filters, oil storage tanks, anti-wear strips, felt cleaning machines.

11. Textile Machinery: Open-width machines, shock absorber baffles, connectors, crank connecting rods, flaring rods, flower sweeping needles, offset axle sleeves, swinging rear beams.

12. Construction Machinery: Bulldozer push plates, materials in dump truck boxes, tractor plow knife liners.

13. Chemical Machinery: Valve bodies, pump bodies, gaskets, filters, gears, nuts, sealing rings, nozzles, plugs, shaft sleeves, corrugated pipes.

14. Port Machinery: Ship components, edge support rollers for bridge cranes, wear-resistant blocks, and other parts.

15. General Machinery: Various gears, bearing bushes, liners, sliding plates, clutches, guiding bodies, brakes, hinges, elastic couplings, roller supports, fasteners, lifting platform sliding components.

16. Dyeing Modifications: Bearing for dyeing machines, scraper sliding plates, liners, seals, and width guide disks.

17. Large Cranes and Heavy Machinery: Placed under the legs of large cranes to provide support.

17. Large Cranes and Heavy Machinery: Placed under the legs of large cranes to provide support.Shandong Ningjin Xinxing Chemical Co., Ltd. has been operating in the ultra high molecular weight polyethylene industry for over 20 years, relying on solid quality and good reputation! We provide attentive service and quality products to all our customers!