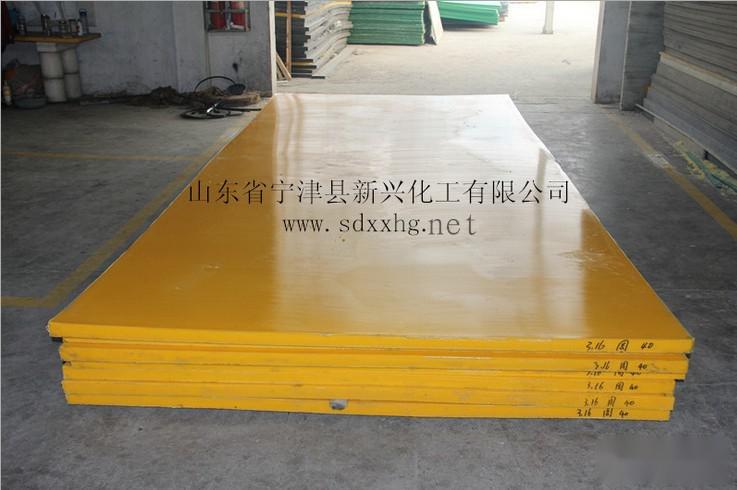

Pressed Ultra-High Molecular Weight Polyethylene Sheet - Introduction to High Molecular Weight Polyethylene SheetPressed Ultra-High Molecular Weight Polyethylene Sheet - Introduction to High Molecular Weight Polyethylene Sheet

The largest production base for ultra-high sheets in the country, a manufacturer of high molecular weight polyethylene sheets, moving towards the top 500 ultra-high molecular weight polyethylene sheet production companies, dedicated to becoming the largest engineering plastics production base in the country! Ningjin Xinxing Chemical Co., Ltd. in Shandong Province sincerely serves you!!

Ningjin Xinxing Chemical Co., Ltd. in Shandong Province has8 large hydraulic presses,4 new electric cutting machines,3 thickness measuring machines,4 CNC engraving machines,4 large milling machines (6 meters X2 meters) and 2 small drilling and milling machines,6 bench drills. We have advanced production and testing equipment in the industry, and we can process according to customer drawings or samples. We have a professional production team, an independent technical department, and a laboratory, ensuring strict quality control. We will strive to be strong and excellent. We look forward to your inquiries!!

Excellent Properties of Ultra-High Molecular Weight Polyethylene Sheet:

1. The wear resistance of ultra-high molecular weight polyethylene sheet is the best among plastics, and the larger the molecular weight, the higher the wear resistance and impact resistance of the material;

2. The impact strength of ultra-high molecular weight polyethylene sheet is high among existing plastics, remaining quite high even at 70°C;

3. Self-lubricating, low friction coefficient, energy-saving, with a wax-like feel.

4. Extremely low water absorption. Therefore, its physical and mechanical properties are independent of humidity factors in the working conditions.

5. Ultra-high molecular weight polyethylene sheet is chemically stable and can resist corrosion from various corrosive media and organic solvents such as acids, alkalis, and salts within a certain temperature and concentration range.

6. Ultra-high molecular weight polyethylene sheet is odorless, non-toxic, non-corrosive, and has physiological recyclability and adaptability.

7. Non-adhesive;

8. When the molecular weight of high-density polyethylene exceeds 500,000, the embrittlement temperature drops to 140°C. Ultra-high molecular weight polyethylene can even maintain a certain mechanical strength at temperatures as low as -269°C under the influence of liquid nitrogen.

Ultra-high molecular weight polyethylene sheet is a thermoplastic special engineering plastic. It combines the superior properties of all plastic materials and is among the highest value of existing engineering plastics. With the development of technology in the plastic processing industry, the application fields of ultra-high molecular weight polyethylene will continue to expand.

Ultra-high molecular weight polyethylene sheet has been widely used in power plants, cement plants, coal mines, metallurgy, sintering, coal washing, chemical industries, etc. Utilizing its unique properties such as low friction coefficient, self-lubrication, low water absorption, and non-stickiness, it serves as linings for coal (material) bins, mine cars, chutes, and other areas prone to sticking and blockage, thereby eliminating the need for installing vibrators or reducing labor intensity, achieving energy savings, improving work efficiency, and increasing economic benefits.

A. Wear-resistant application parts used in the industry.

B. In food machinery and packaging machinery: silent star wheels, worm gears, guide rails, toothed wheels, sliders, baffles, meat processing plant panels, impact plates.

C. In construction machinery: bulldozer blade linings, excavator bucket linings, dump truck box linings.

D. In paper-making machinery: wear-resistant, impact-resistant box covers, seals, guide wheels, scraper valves, dewatering plates, suction tank panels, and flow guide plates.

E. In textile machinery: shock absorber baffles, connectors, shuttle throwers, shuttle rods, and buffer blocks and shafts.

F. In chemical machinery: wear-resistant, corrosion-resistant valve bodies, gaskets, packing, gears, bolts, nozzles, shaft sleeves, transmission machinery, and metal screening pads.

If you have not found a suitable product or feel this product introduction is not detailed enough, please call for consultation. We sincerely look forward to your call... Phone: 0534-5223277 13173333540 Online QQ: 2875013107 Zhang Long from Xinxing Chemical is at your service!