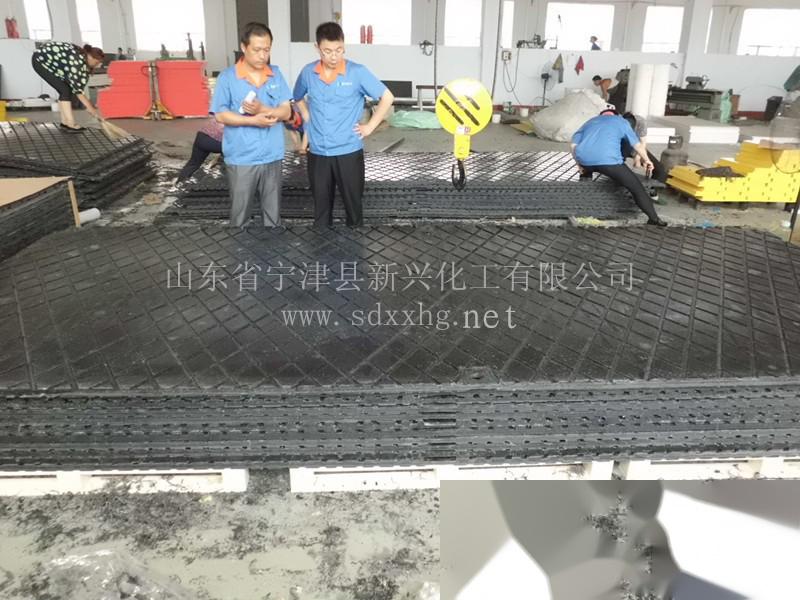

Ultra High Molecular Weight Polyethylene Anti-Slip Board Characteristics Introduction Image

Ultra High Molecular Weight Polyethylene Anti-Slip Board, Polyethylene Anti-Slip Board, High Molecular Polyethylene Anti-Slip Board, UHMWPE Anti-Slip Board, UPE Anti-Slip Board is produced by Xinxing Chemical Co., Ltd. in Ningjin County, Shandong Province.

Our company can produce molecular weights ranging from 500,000 to 10,800,000, and can process anti-slip boards into various shapes according to customer drawings, widely used in wear-resistant, lubricated transportation in parts and machinery, as well as various elevators, escalators, packaging industry, irrigation industry, overlapping lifts, and lubrication of automatic warehouse liquids, wear-resistant and corrosion-resistant parts. We can produce in various colors as long as you provide us with a color sample. Our company is a well-established enterprise with over 20 years of production history. We have rich experience, self-designed machines for high output, our own laboratory for good product quality, and an independent technical department for fast product technology updates.

Product Description:

Xinxing Chemical is at the forefront of international technology in the field of ultra high molecular weight polyethylene.

3. Improved technology effectively enhances the performance of products by 5-25%.

Characteristics of Ultra High Molecular Weight Polyethylene Anti-Slip Board:

1.High Abrasion Resistance: Static friction coefficient is 0.07;

2. Self-Lubricating: Smooth surface, no roughness;

3. Impact Resistance: Good impact performance with no damage.

1. Extrusion Process: Producing thin sheets with molecular weights from hundreds of thousands to 1,500,000, thickness 1-30mm.

2. Compression Process: Producing sheets with molecular weights from 1,500,000 to 10,800,000, thickness 6-400mm

Xinxing Chemical's cutting-edge technology in ultra high molecular weight polyethylene:

1. The products produced have greater strength, higher abrasion resistance, and more uniform thickness.

2. Adhesion: Extruded ultra high molecular weight polyethylene can bond with rubber, stainless steel, aluminum, and other metals. No reinforcement measures are needed for the metal parts, which reduces the required number of components, thereby lowering costs and saving installation time.

4. Corrosion Resistance: Can withstand corrosion from phosphoric acid, alkaline substances, salts, etc.

5. Non-Stick: Low surface tension, difficult to scale;

6. Anti-Static: Anti-static coefficient from 10 to the power of 3 to 6;

7. UV Resistance: Effectively extends the service life of the product.

Reasons for Shandong Xinxing's Professional Advantages:

1, A large number of molds with complete specifications, developed and designed by the company's technical department.

2, Long production history; the company was established in 1999, with strong technical strength and a professional production and sales team.

3, Advanced and complete machinery and equipment, with processing and production equipment in the same industry and an independent laboratory.

4, Product diversity: Widely used in industries such as electricity, ports, docks, coking, coal, papermaking, textiles, chemicals, and environmental protection.

5, Products are sold to domestic and foreign markets, covering various regions. Your satisfaction is our pursuit!!!