The U-shaped locking panel made of polycarbonate is an advanced building system. The entire system uses freely sliding fasteners with a self-locking mechanism, eliminating the need to drill holes in the panels. Panels can be connected using polycarbonate or aluminum connectors, fundamentally solving the problem of thermal expansion and contraction in ordinary polycarbonate flat panels under different usage temperatures. The upright rib design ensures 100% waterproofing on the installation surface and prevents dust accumulation. The innovative U-shaped locking edge design makes installation simpler and faster, provides a more secure connection, and facilitates easier maintenance. This system is widely used for various flat or curved roofs and cladding.

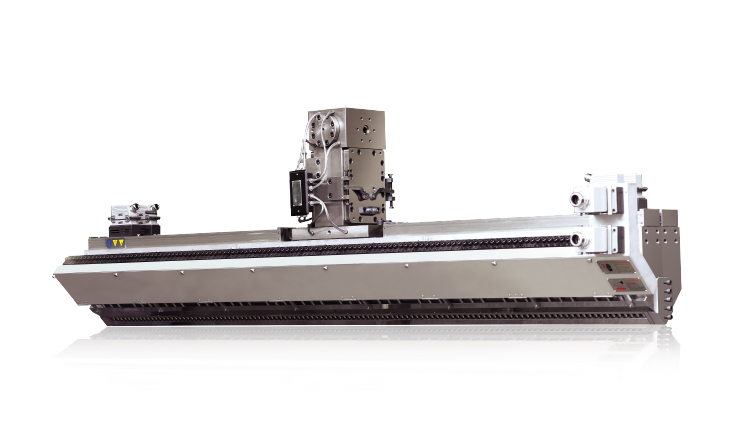

Jiewei Machinery's U-shaped hollow locking panel mold is suitable for producing PC-U shaped locking sun panels with thickness ranging from 4-40mm and width from 600-1050mm. It uses Polyflow three-dimensional dynamic melt rheology analysis software and a one-piece mold design to avoid precision issues and material leakage caused by multi-layer mold combinations. The die head is easy to maintain and clean, extending its service life. Stainless steel heating rods inside the die head are independently controlled by zones to ensure precise temperature control within ±1℃. The forming mold features an independent zone-controlled uniform vacuum device and temperature control system, along with a vacuum sealing edge device, ensuring even airflow distribution and rapid stabilization of the product.

Modified Plastic Producers

Engineering Plastic Producers

Biodegradable Plastic Producers

Others

Others