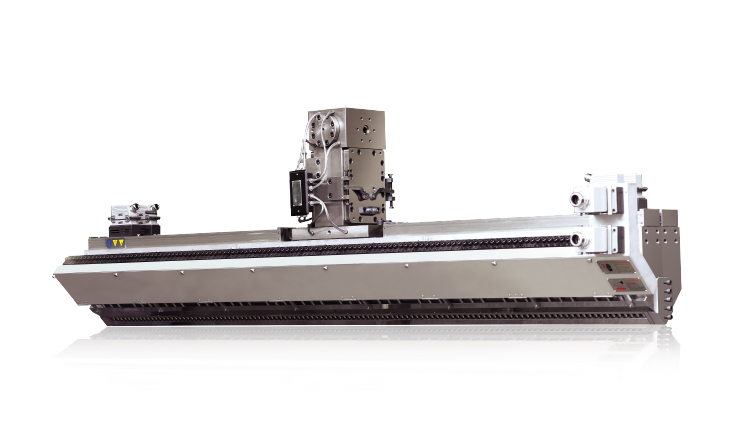

The twin-screw no-drying exhaust PET sheet production line launched by Jinwei Company features low energy consumption, simple process, and convenient equipment use and maintenance. Its unique screw combination structure effectively reduces the viscosity drop of PET resin. The symmetrical thin-walled roller design improves cooling efficiency while increasing capacity and sheet quality. The multi-component feeding device can reasonably control the ratio of virgin material, recycled material, and color masterbatch. The produced sheets can be used in fields such as thermoforming, printing, and packaging.

Model | Multi-layer Co-extrusion | Single Layer | Highly-efficient |

|---|---|---|---|

| Extruder Specification | JW75&36/40-1000 | JW75/40-1000 | JW95&52/44-1500 |

| Thickness of the Product | 0.15-1.5mm | 0.15-1.5mm | 0.15-1.5mm |

| Main Motor Power | 110kw/45kw | 110kw | 250kw/55kw |

| Max Extrusion Capacity | 500kg/h | 450kg/h | 800-1000kg/h |

| Note: The specifications are subject to change without prior notice. | |||

Modified Plastic Producers

Engineering Plastic Producers

Biodegradable Plastic Producers

Others

Others