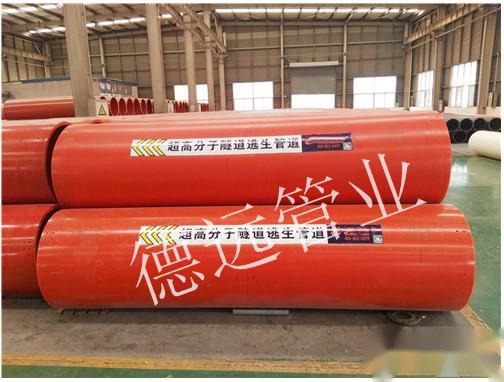

Tunnel Escape Pipe Manufacturer-- Henan Deyuan Rubber and Plastic Products Co., Ltd. is a professional manufacturer specializing in the production and sales of subway tunnel escape pipes. We produce two specifications of tunnel escape pipes: Φ630*22mm and Φ800*30mm, with reasonable prices, guaranteed quality, and sufficient stock. We welcome everyone to inquire and place orders!

800Subway Tunnel Escape Pipe uses new materials to replace ordinary tunnel escape pipes. The new tunnel escape pipe uses a pipe with a diameter of Φ800mm, with a pipe segment length of 3m and a wall thickness of 30mm. The segments can be connected using sleeves with a diameter greater than that of the escape pipe, with 1m connections at each end, temporarily fixed with rubber rings or wooden wedges. To ensure that the pipe can withstand the pressure from collapse debris, the material used for the pipe must ensure its load-bearing capacity and the firmness of the joints, and must be tested in a laboratory before being used in tunnels. Tunnel Escape Pipe Manufacturer

800Subway Tunnel Escape Pipe System Introduction:

A pipeline escape system for tunnel construction accidents, with a safety canopy set at a certain distance from the excavation face of the construction tunnel, connected to one end of the escape pipe; usually, this distance is not greater than 26 meters, and not greater than 21 meters when using the step method. The other end of the escape pipe is close to the secondary lining section of the construction tunnel. This utility model provides a pipeline escape system in the event of a tunnel construction accident.

800Subway Tunnel Escape Pipe requirements for pipe materials: Tunnel Escape Pipe Manufacturer

1. The escape pipe should be connected to the horizontal passage of the tunnel (for vehicles or people) to form a network escape passage.

2. No excavation work is allowed if the escape passage is not properly set up.

3. Ensure that the thickness of the high molecular impact-resistant escape pipe is not less than 10mm.

4. The diameter of the high molecular impact-resistant escape pipe should not be less than 60cm.

5. The length of each pipe section should be 1.5 meters to 2 meters.

6. The high molecular impact-resistant escape pipe can be manually disassembled and has secure connections.

Raw materials are uniformly provided by the Shanghai Chemical Research Institute, with a stable molecular weight greater than 2.5 million, with rich experience.

Large scale: 2000 acres of land, 31 ultra-high pipe production lines, 24-hour production day and night.

After-sales service: One-year warranty, providing measurement and installation after-sales service.

Tunnel Escape Pipe Manufacturer

Henan Deyuan Rubber and Plastic Products Co., Ltd. is a high-tech enterprise integrating R&D, production, and sales, specializing in the production of ultra-high molecular weight polyethylene pipes, 800subway tunnel escape pipes, steel belt reinforced polyethylene (HDPE) spiral corrugated pipes, HDPE pipes, inner and outer coated composite steel pipes, 3PE anti-corrosion pipes, plastic-lined pipes (steel lined PO pipes, steel lined PE pipes, steel lined fluorine pipes), rubber-lined pipes, and other series of multi-specification pipe and fitting products. The products are mainly used in the chemical, electric power, mining, metallurgy, pharmaceutical, water conservancy, municipal, construction, environmental protection, dredging, and coal washing industries.

Interested customers are welcome to visit our factory for inspection, and we look forward to your visit!