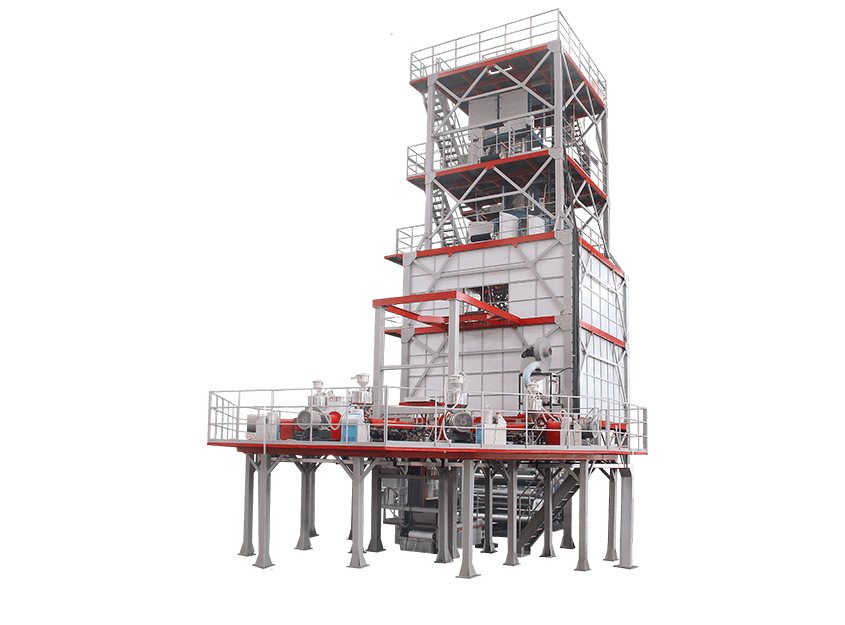

Jinming ClassicX series blowing film machine lines are mid-to-high-end models optimized from Jinming's existing machine products, offering customization and high production capacity. Based on standard configurations, these machines can be customized according to the actual production processing needs and process conditions of customers, meeting high-quality production requirements such as film uniformity control, film transparency, film stiffness and toughness, and film output.

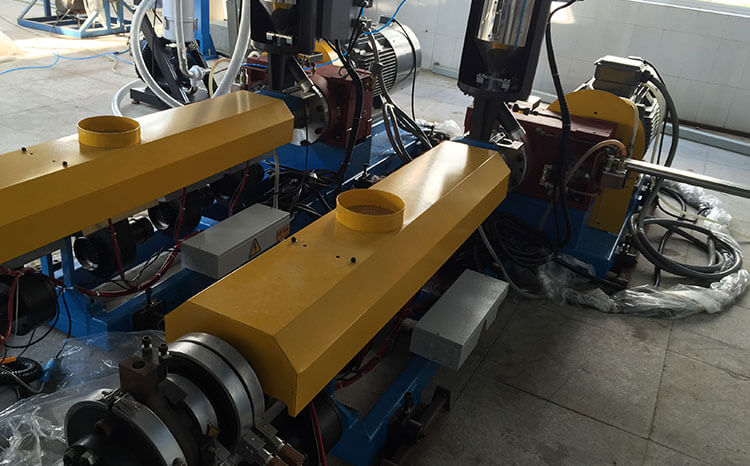

Component Introduction

The die head is designed through simulation based on the processing characteristics of TPU materials, fully considering rheology to reduce melt pressure loss, minimize melt residence time, comply with shear stress within the minimum and maximum film thickness, eliminate boundary instability, ensure uniform elastic deformation, and avoid any retention areas.

Considering that TPU films have excellent stretch elasticity, maintaining stable tension and minimizing traction force during the traction process is crucial. The entire traction system has been improved in design, using closed-loop tension control to achieve constant tension, ensuring stable tension.

The multi-functional winder meets the requirement of low winding tension for TPU films. It uses a dedicated winding-type frequency converter with tension control taper calculation function to drive the winding motor, ensuring stable tension during winding and taper control. Additionally, the winder features automatic core release, automatic film breakage, automatic roll change, automatic unloading, dual cutting, and dual receiving functions, effectively reducing operator labor intensity.

Technical Parameters

| Model | M2B-1700Q-C | M2B-2300Q-C | M2B-2800Q-C | M3B-3200Q-C |

| Layers | 2 | 2 | 2 | 3 |

| Maximum Product Width | 1600mm | 2100mm | 2500mm | 3000mm |

| Conventional Product Thickness | TPU 0.015-0.05mm; PE 0.01-0.03mm |

TPU 0.015-0.05mm; PE 0.01-0.03mm |

TPU 0.015-0.05mm; PE 0.01-0.03mm |

TPU 0.015-0.05mm; PE 0.01-0.03mm |

| Suitable Raw Materials | PE, TPU | PE, TPU | PE, TPU | PE, TPU |

| Screw Diameter | Φ75×2mm | Φ80mm×2 | Φ90×2mm | Φ90×3mm |

| Maximum Extrusion Capacity | 320kg/H | 400kg/H | 460kg/H | 690kg/H |

| Total Installed Power | 250kw | 380kw | 388kw | 520kw |

| Highest Traction Speed | 80m/min | 80m/min | 80m/min | 80m/min |

| Dimensions (L×W×H) | 15×7×11.5m | 17×7×14.5m | 18.4×9.4×14.5m | 19×10×15m |

In addition to the above models, we also provide MB-2800T, M2B-600, M2B-2500Q-C, M3B-2800Q-C, and other models.

Application Fields

Modified Plastic Producers

Engineering Plastic Producers

Biodegradable Plastic Producers

Others

Others