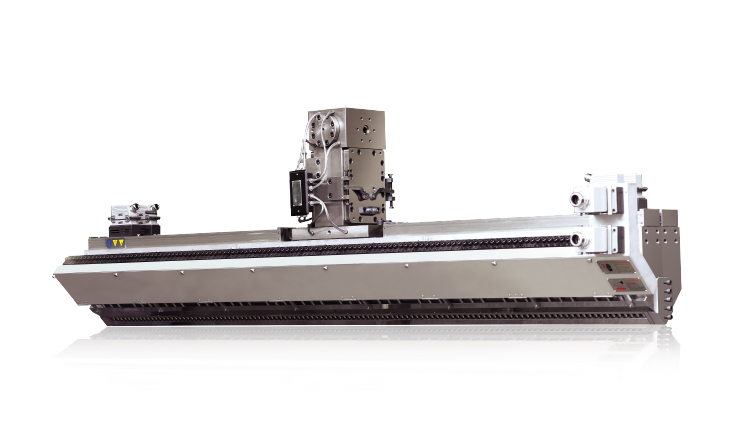

Jinwei Machinery has developed a TPO+PP foam substrate composite production line, utilizing a specially structured TPO screw for uniform plasticization. Combined with unique composite technology, this process results in high bonding strength without elongation deformation or formaldehyde emissions. This is Jinwei's latest domestically leading composite production line targeting the automotive interior materials market. The composite material offers flexible operation, high efficiency, and one-step processing of TPO surface textures. Products made from this process, which are hot-pressed and molded in one step with the substrate, completely revolutionize traditional composite methods. These products are widely used in high-end car interior components, headliners, pipelines, etc.

Technical Parameters

| Model | JW100/33 | JW120/33 |

|---|---|---|

| Product Thickness | 0.5mm | 0.5mm |

| Maximum Output Capacity | 120KG/h | 220KG/h |

| Main Motor Power | 55KW | 132KW |

| Note: The information listed above is for reference only. The production line can be customized according to customer requirements. | ||

Modified Plastic Producers

Engineering Plastic Producers

Biodegradable Plastic Producers

Others

Others