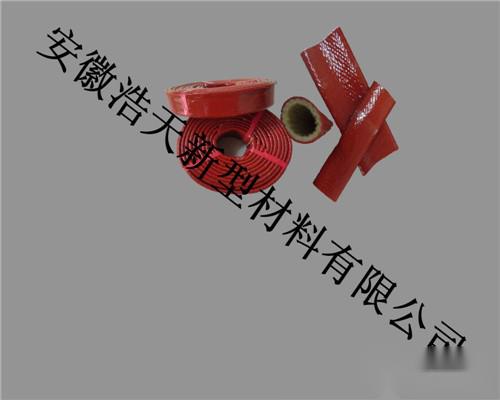

Haotian Brand Fireproof and High-Temperature Resistant SleeveFeatures and Applications

1.Safe and environmentally friendly, protecting workers' health

Alkali-free glass fiber has excellent tensile strength, is wrinkle-resistant and break-resistant, is sulfur-resistant, produces no smoke, halogen, or toxins, is pure oxygen non-flammable, and has good insulation properties. After being cured with organic silicone, its safety and environmental protection performance is further enhanced, effectively protecting workers' health and reducing the incidence of occupational diseases. Unlike asbestos products, which pose significant health and environmental risks.

2.Superior high-temperature resistance

The surface of the high-temperature sleeve contains both 'organic groups' and 'inorganic structures' within its silicone structure. This unique composition and molecular structure combine the characteristics of organic materials with the functions of inorganic materials. Compared to other polymer materials, its standout feature is its high-temperature resistance. With a main chain structure based on silicon-oxygen (Si-O) bonds, the bond energy of C-C bonds is 82.6 kcal/mole, while the bond energy of Si-O bonds in organosilicon is 121 kcal/mole, resulting in high thermal stability. Under high temperatures (or radiation exposure), the chemical bonds of the molecules do not break or decompose. Organosilicon can withstand not only high temperatures but also low temperatures, allowing it to be used over a wide temperature range. Its chemical and physical mechanical properties vary little with temperature changes.

3.Anti-splash, multi-layer protection

In the smelting industry, the medium temperature in electric furnaces is extremely high, easily leading to high-temperature splashes (similarly in the welding industry). After cooling and solidifying, slag forms on pipelines or cables, causing the rubber outer layer to harden and eventually become brittle and crack. This can damage unprotected equipment and cables. The high-temperature sleeve with multiple layers of silicone coating provides multiple safety protections, with high-temperature resistance up to 1300 degrees Celsius, effectively blocking splashes of molten iron, molten copper, and molten aluminum, and preventing damage to surrounding cables and equipment.

4.Insulation, energy-saving, radiation-resistant

In high-temperature workshops, many pipelines, valves, or equipment have very high internal temperatures. Without protective materials, it容易造成人员灼伤或热量流失等。Haotian耐高温套管,具有比其他高分子材料更好的热稳定性以及耐辐照和保温隔热的作用,防止意外,减少能耗,也可防止管道内介质的热量直接传递给周围环境而使车间的温度过高,节约降温成本。

5.Moisture-proof, oil-proof, climate aging-resistant, pollution-resistant, extending equipment lifespan

The high-temperature sleeve has strong chemical stability, and organosilicon does not react with oil, water, acids, or alkalis. Within 260℃, it can be used for a long time without aging, and its lifespan in natural environments can reach decades. It effectively protects pipelines, cables, and equipment in these environments, significantly extending their service life.

6.Ozone-resistant, voltage-resistant, arc-resistant, and corona-resistant

The surface is coated with organosilicon, whose main chain is Si-O-, making it resistant to decomposition by ultraviolet light and ozone. The high-temperature sleeve has excellent electrical insulation properties, with its dielectric loss, voltage resistance, arc resistance, corona resistance, volume resistivity, and surface resistivity ranking among the best in insulating materials. Moreover, their electrical performance is minimally affected by temperature and frequency. Therefore, they are stable electrical insulating materials widely used in the electronics and electrical industries.

7.Flame retardant, reducing the incidence and spread of fires

If flammable or toxic media are transported through the pipeline, leaks can easily lead to fires or casualties; cables are also often burned due to local high temperatures. The high-temperature sleeve is made from extremely heat-resistant glass fiber, with a surface silicone added with appropriate flame retardants and other special materials, giving it excellent flame retardant properties. Even if a fire occurs, it can prevent the spread of flames and still protect the integrity of internal pipelines for a longer time, providing ample time for rescuing important data and information. 7 Common Uses:

High-temperature areas and heating areas in industries such as steel, smelting, shipbuilding, and chemical engineering, including cables, fluid pipelines, rolling mill cables, oil pipes, saw-cut edge cables, generator sets, electrical voltage equipment, large buildings, hydraulic systems, automotive wiring harnesses, and exhaust pipes. 8 Testing Items and Results

High-Temperature Bending Test

After heating in a constant temperature furnace at 260℃ for 48 hours, no aging cracks or delamination of the coating occurred on the surface

Low-Temperature Bending Test

After heating in a constant temperature furnace at -70℃ for 1 hour, no cracks or delamination of the coating occurred on the surface.

Coating Test

After continuous use testing in a constant temperature furnace, no surface peeling or dissolution occurred.

Burning Test

Flame-retardant, self-extinguishing, and no spontaneous combustion (meets UL 'VW-1' and CSA 'HFS' tests)

Temperature Resistance Test

( 2000hr ) 260 ℃ heating test normal without abnormalities

( 30sec ) 1200℃ heating test glass fiber intact

Flame Retardancy Test

Burning speed not less than 45s/25mm

---- SRG-1-7kv SRG-1-4kv,(the motor insulation class can reach a level higher thanH levelC level)

Normal Low Insulation Breakdown Voltage 7.0 kv / min 4.0 kv / min

Normal Average Insulation Breakdown Voltage 10.0 kv / min 7.0 kv / min