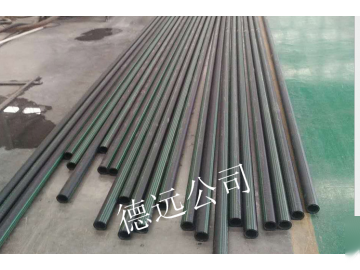

Henan Deyuan Rubber and Plastic Products Co., Ltd. produces underground fuel station oil pipelines, with a full range of specifications including Φ32, Φ40, Φ63, Φ75, Φ110, and Φ125 mm. The manufacturer ships directly, offering low prices and comprehensive after-sales service, with a professional installation team available for on-site guidance during pipeline installation if needed.

Most gas stations in Western countries use EVOH fuel station oil pipelines. Metal pipelines have largely been replaced, with only a small number of gas stations still using metal composite pipelines. Underground pipelines in Europe and America have been standardized by various regulations, such as the UL971 certified by Underwriters Lab (Northbrook, IL) in the United States, and EN14125 or KIWA in Europe. These standards not only enhance the operational safety of pipelines but also encourage the use of more environmentally friendly technologies.

Development Trends of Underground Fuel Station Oil Pipelines:

Since 2001, nearly ten thousand gas stations have adopted composite materials. Composite materials are also widely used in the petrochemical industry, including oil exploration, oil and gas collection and transportation, and petrochemical refining, especially in recent years, the development has been rapid. It is believed that in the near future, with the development of composite materials, they may completely replace traditional seamless steel pipe processes in gas stations.

The tough flexible structure of the materials gives the gas station pipeline system strong resistance to pressure, impact, puncture, stretching, and ground movement. Seamless steel pipes cannot be stretched, and underground installation generally involves rigid connections, which can be affected by geological settlement and seasonal temperature variations, posing safety risks of pipeline deformation and leakage. In contrast, composite materials have good flexibility, a low thermal expansion coefficient, and can effectively resist ground stress without affecting the tightness of connections due to ground movements, thereby ensuring the integrity of the gas station pipeline system.

Most gas stations in Western countries use EVOH fuel station oil pipelines. Metal pipelines have largely been replaced, with only a small number of gas stations still using metal composite pipelines. Underground pipelines in Europe and America have been standardized by various regulations, such as the UL971 certified by Underwriters Lab (Northbrook, IL) in the United States, and EN14125 or KIWA in Europe. These standards not only enhance the operational safety of pipelines but also encourage the use of more environmentally friendly technologies.

A committee comprising pipeline manufacturers, oil companies, insurance companies, legislators, and material suppliers is currently preparing a new version of the UL standard, focusing on introducing new types of fuels. Currently, biodiesel and gasoline are rapidly expanding in the U.S. market. Therefore, the new standards aim to ensure that future pipeline designs are compatible with new fuels (such as biodiesel and alcohol-rich gasoline) as much as possible. This standard also aims to use better pipelines and more accurate control methods to reduce leakage of oil products through the pipe walls. A typical American gas station generally has a pipeline that is 500 feet (152m) long with a 2-inch outer diameter (5.1cm). The allowable oil product leakage is 18 grams/day. Current commercial pipeline performance is quite good, with most gas stations experiencing leakage of less than 5 grams per day.

The development trend of multi-layer composite oil pipelines for gas stations compared to traditional steel pipelines includes the following advantages:

1. Long lifespan. Traditional gas station oil pipelines usually require anti-corrosion treatment before being buried underground; even in neutral non-corrosive soils, the average lifespan is only 10 years. In contrast, gas station oil pipelines can achieve a lifespan of up to 50 years without maintenance, effectively reaching the design lifespan limit of gas stations.

2. Safety and anti-static properties. The inner surface of gas station oil pipelines is smooth, with good hydraulic characteristics, which can reduce the generation of static charges. Moreover, composite materials are designed with multiple layers, including an independent conductive layer that has anti-static properties, effectively preventing static discharge and fully complying with construction standard requirements (volume resistivity less than 108Ω.m, surface resistivity less than 1010Ω).

3. Safe and efficient installation. The construction requirements for underground fuel station oil pipelines are high, especially during renovations or repairs, which may involve welding operations in the presence of residual flammable and explosive oil products and gases. Composite materials typically use customized connecting elbows and fittings, employing heat fusion or adhesive principles, thus avoiding open flame operations as required in traditional processes. Seamless steel pipeline installations generally require enhanced anti-corrosion measures and are buried in trenches, with an average construction time of 10-12 days for a gas station. In contrast, composite materials do not require anti-corrosion treatment and can be directly buried, with an average construction period of only 3-5 days.

4. Corrosion resistance. Gas station oil pipelines have excellent corrosion resistance and do not rust. Since gas station oil pipelines are primarily underground, traditional steel pipelines are subject to limitations from soil pH and chemical composition and require multiple anti-corrosion measures before being buried. In contrast, composite materials, due to their special chemical composition, do not undergo electrochemical reactions and are less likely to interact with other chemical components in the soil, providing high chemical stability and excellent resistance to acidic and alkaline solutions. In areas with strong soil corrosion and high humidity, they show significant advantages in corrosion and rust resistance compared to steel pipelines.

5. High pressure resistance and toughness. Gas station oil pipelines are generally designed with a multi-layer structure, using chemical molecular bonding methods to connect different layers, making the multi-layer pipeline a solid whole and eliminating the risks of leakage and swelling caused by delamination. Their pressure resistance is higher than that of seamless steel pipes, with working pressure reaching up to 4.0 MPa and negative pressure up to 0.1 MPa, fully meeting the requirements of construction standards that specify a maximum working pressure of non-metallic composite pipes of no less than 0.35 MPa.

6. Convenient transportation. The weight of underground fuel station oil pipelines can be as little as one-tenth that of steel pipes, and due to their good flexibility and bendability, they can be bundled for compact transportation. The transportation of pipes is not limited by processing length, greatly facilitating the logistics of material transportation.

Henan Deyuan Rubber and Plastic Products Co., Ltd. is a high-tech enterprise integrating research and development, production, and sales. It specializes in producing underground fuel station oil pipelines, oil well pipes, ultra-high molecular weight polyethylene pipelines, tunnel escape pipes, steel belt reinforced polyethylene (HDPE) spiral corrugated pipes, HDPE pipes, internally and externally coated composite steel pipes, 3PE anti-corrosion pipes, and lined pipes (steel-lined PO pipes, steel-lined PE pipes, steel-lined fluorine pipes), and rubber-lined pipes, among other series of various specifications of pipe fittings and pipes. The products are mainly applied in industries such as chemical, electric power, mining, metallurgy, pharmaceuticals, water conservancy, municipal, construction, environmental protection, dredging, and coal washing.

We strive for survival through quality and development through reputation, and we warmly welcome your patronage, sincerely looking forward to serving you!

Address: Entrepreneurial Avenue, Yongkang Industrial Cluster, Luoyang City