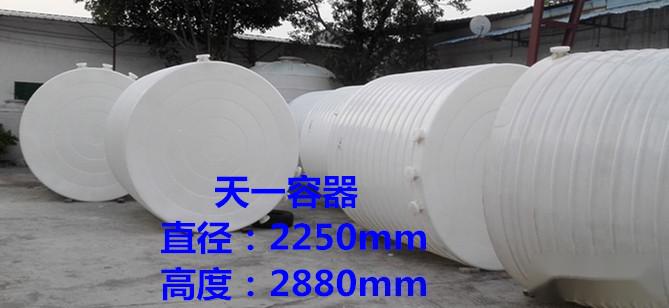

1, plastic PE tank, also known as PE chemical tank, PE tank, plastic barrel, PE barrel, acid-alkali tank, plastic tank, PE water tank, water tower, water storage tank, measuring tank, chemical mixing tank, PE chemical tank container, acid-alkali storage tank, anti-corrosion tank, chemical storage tank, etc. Plastic PE chemical storage tank refers to the seamless plastic (polyethylene) storage and transportation equipment series, which is one of the three major series of storage tanks. This series of products uses a unique formula to modify and increase polyethylene (PE) as raw material, and adopts a special process of integral one-time molding (rotational molding process). Therefore, the storage tank also has the advantages of no welding seams, no leakage, non-toxic, light weight, anti-aging, impact resistance, corrosion resistance, long service life, and compliance with hygiene standards. The production process of plastic PE chemical storage tank is: rotational molding process, also known as rotational molding, rotational casting molding. It is a hollow forming method for thermoplastic plastics. The powder or paste-like PE material is first injected into the mold, and then the material is evenly distributed in the mold cavity and melted through the heating of the mold and the rotation of the longitudinal and transverse rolling of the water, by the gravity and centrifugal force of the material itself. After cooling, the hollow product is obtained by demolding. Due to the low rotational speed of rotational molding, the product has almost no internal stress, and it is not easy to deform or collapse. The product has a smooth and flat surface.

2, product characteristics:

a, tough texture: made of polyethylene (Polyethyline), light and tough, easy to handle, earthquake-resistant, impact-resistant.

b, excellent resistance to drugs: resistant to all kinds of acids and alkalis.

c, clean and beautiful: the appearance is sleek and beautiful, not easy to get dirty, and dirt can be easily removed.

d, economical and durable: the barrel is integrally formed without adhesive joints, not easy to break.

e, heat and freeze resistance: good heat and freeze resistance, can be used at temperatures from 80 to -40 degrees Celsius.

f, leakage: the water outlet joint is made of the same material as the barrel, processed by heat fusion method, which can avoid leakage and the trouble of urgent replacement.

g, specific specifications, colors can be customized according to customer needs!

3, our company's plastic container products are divided into 4 levels, including A level, B level, special level, UL level as follows:

A level: mainly used for indoor storage of water

B level: mainly used for storing drinking water, industrial use for low acidity and low alkalinity (increased thickness based on A level)

Special grade: mainly used for industrial use of low concentration strong acid and strong alkali (increased thickness based on B level)

UL grade: mainly used for industrial use of high concentration strong acid and alkali (increased thickness based on special grade)

4, explanation:

The water tower comes with a screw cap, which can be removed and installed; the water tower itself has no holes, and can be opened for inlet and outlet according to customer requirements free of charge, and equipped with joints. Please specify if you need to open the hole, thank you.

Compliant with food grade hygiene standards, also compliant with industrial grade requirements, this product is resistant to acid and alkali, corrosion-resistant, and can be directly used for drinking water. The water tank is processed with standard inlet and outlet, if improvement is needed, please specify when placing an order.

b, the size is the mold size, the product size will shrink by 3%-5%.

c, for packaging chemicals, please order special grade products and match with special interfaces.

d, for liquid storage, it is recommended to add a reinforcement sleeve.

Note: If the above models do not meet your requirements, we can also customize molds for you

5, about after-sales service:

1. Buyers please note: industrial products are huge in volume, there may be slight scratches during transportation, but it does not affect normal use. If it does affect, you can exchange or return the goods for free. Please rest assured to buy!

2. The products are all photographed in the store owner's warehouse, there may be slight color difference, without any exaggeration or fine decoration, only showing buyers the true side! Welcome to inquire!

6, main products: Nanning Tianyi's main products include: PE tanks, plastic tanks, chemical tanks, anti-corrosion tanks, plastic water towers, conical bottom barrels, plastic round barrels, plastic square boxes, dosing boxes, floating boxes, anti-collision barrels, water horses, pickling tanks processing, steel-lined plastic products, plastic containers, plastic special-shaped parts welding, transportation tank welding, FRP waste gas treatment equipment and FRP large containers, and undertake various special-shaped parts processing.

Barrels, plastic round barrels, plastic square boxes, dosing boxes, floating boxes, anti-collision barrels, water horses, pickling tanks processing, steel-lined plastic products, plastic containers, plastic special-shaped parts welding, transportation tank welding, FRP waste gas treatment equipment and FRP large containers, and undertake various special-shaped parts processing.