Sheet Die Series-JW-P-K1

Rapid opening die with a pull-push adjustment mechanism for the upper lip and a flexible lower lip that allows for quick online thickness adjustments without stopping the machine. The adjustable range can reach up to 5mm, with a 45-degree throttle bar adjustment device. Suitable for producing single or multi-layer sheets.

Sheet Die Series-JW-P-D1

In-die composite die utilizing multiple flow channels for in-die lamination, effectively improving the precision of layer thickness. It features micro-adjustable upper lips, fixed lower lips, and a 45-degree throttle bar for core layer adjustment. Ideal for manufacturing multi-layer co-extruded sheets.

Sheet Die Series-JW-P-C2

Die with a gradually changing droplet-shaped flat shoulder flow channel combined with triangular distribution technology and stepped stabilization, effectively preventing die deformation caused by high pressure during extrusion. The upper lip is manually extendable for precise elastic adjustment, and the flat throttle bar eliminates material retention, solving issues related to prolonged residence time. The lower lip is interchangeable based on different thickness requirements. Suitable for producing single or multi-layer sheets from PC, PS, PP, PE, PLA, PVC, etc.

Sheet Die Series-JW-P-C1

Standard coat-hanger flow channel design, allowing for adjustable upper lips and interchangeable lower lips along with a 45-degree throttle bar. Suitable for producing single or multi-layer sheets from PVC, PS, PP, PE, PC, with product thickness ranging from 0.8 to 12mm.

Sheet Die Series-JW-P-AT1

Automatic adjustment die equipped with an automatic control unit in the upper lip, offering both manual and automatic adjustment options. The manual adjustment range is 1mm, while the automatic adjustment range is 300um. Suitable for producing single or multi-layer sheets or films of varying widths from PC, PS, PP, PE, PLA.

Sheet Die Series-JW-P-A1

Standard coat-hanger flow channel design with micro-adjustable upper lips. Suitable for producing single or multi-layer sheets from PET (APET, PETG), PC, PS, PP, PLA, with a width ≤2100mm and thickness ranging from 0.14 to 2mm.

Sheet Die Series-JW-P-K1

Rapid opening die with a pull-push adjustment mechanism for the upper lip and a flexible lower lip that allows for quick online thickness adjustments without stopping the machine. The adjustable range can reach up to 5mm, with a 45-degree throttle bar adjustment device. Suitable for producing single or multi-layer sheets.

Sheet Die Series-JW-P-D1

In-die composite die utilizing multiple flow channels for in-die lamination, effectively improving the precision of layer thickness. It features micro-adjustable upper lips, fixed lower lips, and a 45-degree throttle bar for core layer adjustment. Ideal for manufacturing multi-layer co-extruded sheets.

Sheet Die Series-JW-P-C2

Die with a gradually changing droplet-shaped flat shoulder flow channel combined with triangular distribution technology and stepped stabilization, effectively preventing die deformation caused by high pressure during extrusion. The upper lip is manually extendable for precise elastic adjustment, and the flat throttle bar eliminates material retention, solving issues related to prolonged residence time. The lower lip is interchangeable based on different thickness requirements. Suitable for producing single or multi-layer sheets from PC, PS, PP, PE, PLA, PVC, etc.

Sheet Die Series-JW-P-C1

Standard coat-hanger flow channel design, allowing for adjustable upper lips and interchangeable lower lips along with a 45-degree throttle bar. Suitable for producing single or multi-layer sheets from PVC, PS, PP, PE, PC, with product thickness ranging from 0.8 to 12mm.

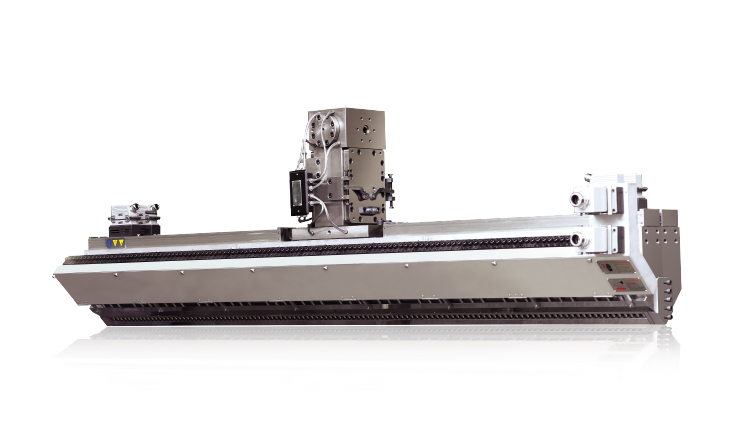

Sheet Die Series-JW-P-AT1

Automatic adjustment die equipped with an automatic control unit in the upper lip, offering both manual and automatic adjustment options. The manual adjustment range is 1mm, while the automatic adjustment range is 300um. Suitable for producing single or multi-layer sheets or films of varying widths from PC, PS, PP, PE, PLA.

Sheet Die Series-JW-P-A1

Standard coat-hanger flow channel design with micro-adjustable upper lips. Suitable for producing single or multi-layer sheets from PET (APET, PETG), PC, PS, PP, PLA, with a width ≤2100mm and thickness ranging from 0.14 to 2mm.

Modified Plastic Producers

Engineering Plastic Producers

Biodegradable Plastic Producers

Others

Others