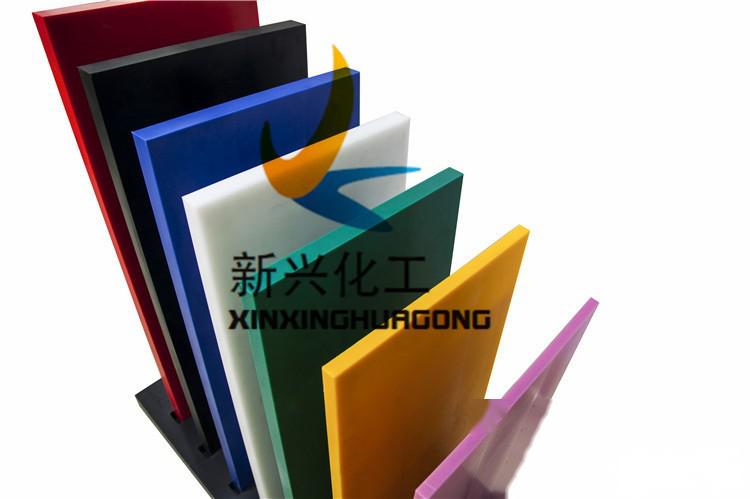

Ultra-high molecular weight polyethylene is a thermoplastic engineering plastic that combines the superior properties of all plastics. Its mechanical properties exceed those of high-density polyethylene, featuring outstanding abrasion resistance, impact resistance, low-temperature wear resistance, stress crack resistance, high-temperature creep resistance, low friction coefficient, self-lubrication, excellent chemical corrosion resistance, fatigue resistance, noise damping, and resistance to nuclear radiation among other excellent properties. It can replace materials such as carbon steel, stainless steel, bronze, etc., in various sectors including textiles, papermaking, food machinery, transportation, medical, coal mining, and chemical industries due to its wear resistance and impact resistance.

Advantages of ultra-high molecular weight polyethylene boards:

1, The wear resistance is the highest among plastics, and the greater the molecular weight, the higher the material's wear resistance and impact resistance;

2, The impact strength is one of the highest values among existing plastics, maintaining considerable impact strength even at70°C;

3, Self-lubricating;

4, Extremely low water absorption. Therefore, its physical and mechanical properties are independent of the humidity factors in the working conditions;

5, Chemically stable, resistant to corrosion from acids, bases, salts, and various corrosive media as well as organic solvents within a certain temperature and concentration range;

6, Odorless, non-toxic, non-smelling, inherently non-corrosive, with physiological circulation and physiological adaptability;

7, Non-adhesive;

8, When the molecular weight exceeds500,000, the embrittlement temperature drops to140°C. Ultra-high molecular weight polyethylene can even maintain mechanical strength at temperatures as low as269°C under liquid nitrogen;

Shandong Xinxing Chemical looks forward to your inquiry.