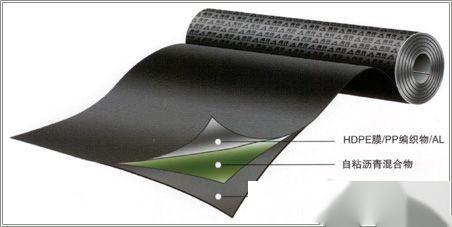

Shandong Tianhai wide-width high molecular self-adhesive waterproof membrane is primarily made from homogeneous sheets of ethylene-vinyl acetate (EVA), high-density polyethylene (HDPE), and polyvinyl chloride (PVC), with a "self-adhesive layer" coated on the surface, and further covered with a silicone-coated release film. According to project requirements, geotextiles can be compounded on the polymer layer to enhance the strength of the membrane.

Product Types:

Shandong Tianhai high molecular self-adhesive waterproof membranes are mainly divided into single-sided adhesive polymer pre-laid waterproof membranes, high-density polyethylene (HDPE) self-adhesive film waterproof membranes, HDPE self-adhesive waterproof membranes, single-sided self-adhesive polymer waterproof membranes, double-sided self-adhesive polymer waterproof membranes, EVA single-sided self-adhesive waterproof membranes, HDPE single-sided self-adhesive waterproof membranes, EVA double-sided self-adhesive waterproof membranes, and HDPE double-sided self-adhesive waterproof membranes.

Product Specifications:

Thickness options: 1.5mm, 2.0mm, 3.0mm, with roll length customizable according to user needs.

Width: 2.0m.

Application Range:

Used in underground tunnels, external waterproofing for internal wall applications, subways, etc.

Product Features:

◎ Skin-style waterproofing, thoroughly resolves the water leakage issue in high molecular waterproof membranes;

◎ High tensile and tear strength;

◎ Good bonding and sealing properties, effectively prevents water leakage; excellent acid and alkali resistance and other chemical properties;

◎ Puncture-resistant self-healing properties, with high elongation;

◎ Non-toxic and odorless, meets environmental protection requirements, and is easy and quick to install;

◎ Membranes should be stored in a dry, ventilated environment to prevent sun exposure and rain;

◎ Avoid contact with organic solvents and keep away from fire sources;

◎ Storage period is one year from the date of production.

Packaging and Transportation:

◎Products are packaged in plastic woven bags;

◎During transportation, prevent sun exposure and rain, avoid fire sources, and prevent collisions to ensure packaging remains intact;

◎When storing products, keep them in a cool, ventilated place, lay the rolls flat, stack no more than four layers, and keep away from fire sources;

◎Under normal storage and transportation conditions, the product shelf life is 12 months. If the shelf life is exceeded, inspections can be conducted according to the specified items in this standard. If the composite requirements are still met, the product can be used.