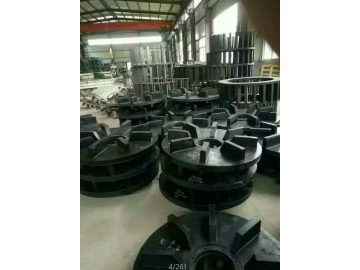

The models of impeller cover plates produced by the company include XJK1-7A (0.15~5.8m3), SF (0.15~32m3), XCF (2~32m3), BS-K (4~32m3), LCH (5m3), JJF (0.15~32m3), KYF (2~32m3), BS (4~32m3), CHF (3.5m3), regrinding mill impeller bushings (∮600--∮800), stirring tank impellers (∮1--∮2.5m3), etc.

Our company guarantees quality while offering the lowest prices online to ensure your satisfaction. The flotation machine impeller cover plates produced by our factory are made of three materials: polyurethane, nylon, and wear-resistant rubber, each with its own advantages for users to choose from.

Flotation machine impeller cover plate rubber lining for flotation machine rotors and stators are the central components of the flotation machine. They are made with a steel frame material and a wear-resistant layer made of rubber with excellent anti-wear, anti-corrosion, and oil resistance properties, using high-performance adhesives and special vulcanization processes. The products have good wear resistance, impact resistance, tear resistance, and chemical stability. Based on the PH value and other working conditions provided by the mineral processing plant, we scientifically select rubber formulations that are wear-resistant, corrosion-resistant, and oil-resistant, using modern design methods such as CAD and UGS to design high wear-resistant rubber flotation machine stators and rotors. The production cycle usually does not exceed 50 days, and the extra-large 4500 ton flat vulcanizing machine provides reliable support for the production of large flotation machine rotors and stators.

The products have the following advantages:

1, The wear resistance is 1.5 times that of ordinary rubber.

2, Light weight, easy to load and unload, convenient and quick maintenance.

3, Acid-resistant, alkali-resistant, and oil-resistant with a long service life.

The flotation machine impeller cover plates are available in three materials: polyurethane, nylon, and wear-resistant rubber, each with its own advantages for users to choose from.