SCF Plastic Recycling Pelletizing Machine Melt Filtration Equipment

The new SCF self-cleaning filtration system enables continuous recycling extrusion without downtime, making it particularly suitable for re-pelletizing highly contaminated materials.

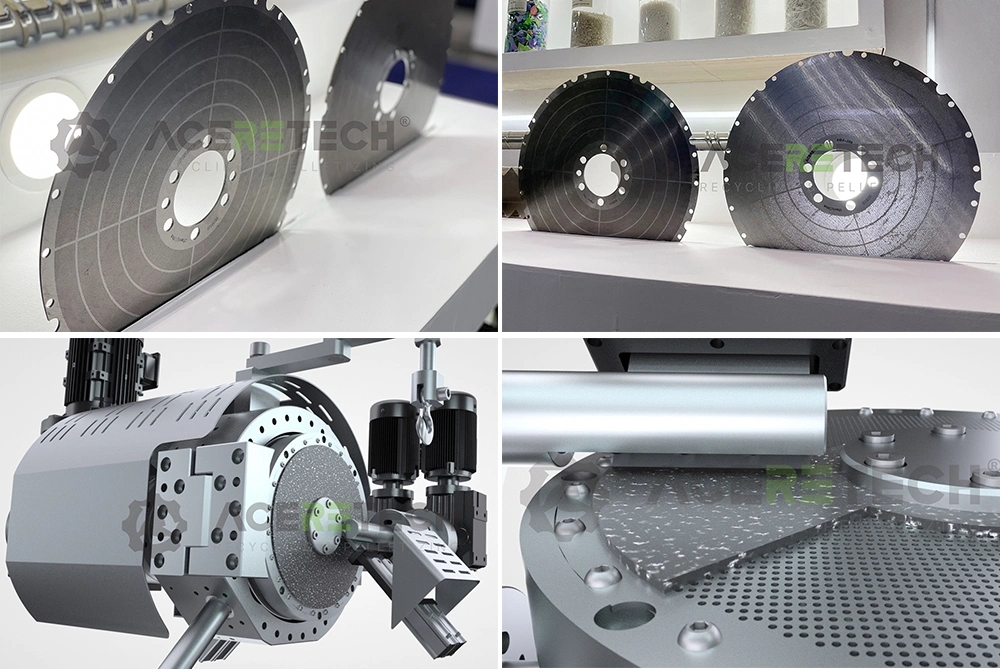

【Screenless Design】

Unlike traditional screen changers that require timely replacement of dirty screens, the SCF system offers continuous filtration performance by automatically removing contaminants from the surface of the steel screen plate. It features high automation, large processing capacity, and can significantly increase the recovery rate of recycled material. The dross discharge ratio (the ratio of dross volume to plastic content in the dross) can reach 1:1.

SCF's effective precision can reach up to 120 mesh. Using Aceretech SCF self-cleaning filters can more efficiently produce pellet lines with hourly output exceeding one ton.

The SCF filtration system consists of hardened steel screen plates, a rotating unit, hydraulic components, cleaning blades, and a discharge screw.

The SCF filtration system can handle and remove up to 5% of contaminants in melt flow, separating them into paper, wood, aluminum, unmelted plastics, and rubber, among others.

【Product Specifications】

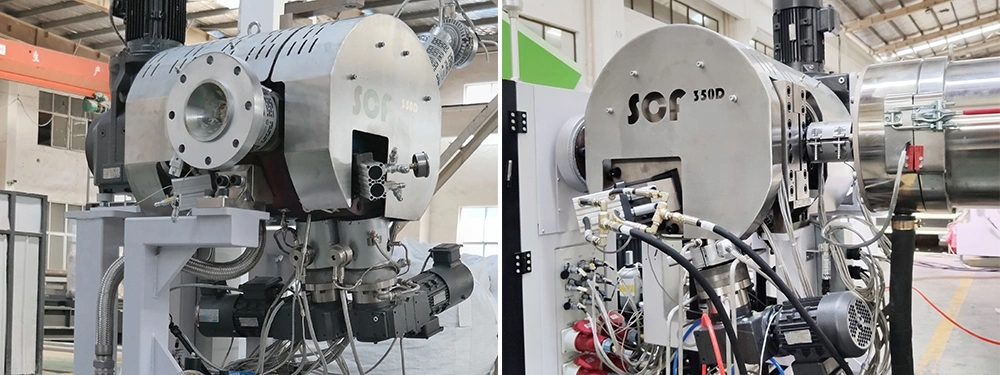

| Type | SCF 350 | SCF 350-D |

| Diameter | 350mm*1 | 350mm*2 |

| Filter Area | 961cm² | 1922cm² |

| Mesh Size (mesh) | 40-120 | 40-120 |

| Mesh Size (micron) | 120-380 | 120-380 |

| Hole Shape | Cylindrical/Conical | Cylindrical/Conical |

| Manufacturing Process | CNC/Laser | CNC/Laser |

| Maximum Melt Pressure | 200bar | 200bar |

| Maximum Melt Pressure Difference | 150bar | 150bar |

| Liquid Throughput Efficiency | 200-500kg/h | 500-1000kg/h |

| Rotating Motor Power | 2.2kw | 2.2kw |

| Discharge Screw Motor Power | 0.37kw | 0.37kw*2 |

| Heating Power | 28kw | 33kw |

| Discharge Method | Screw | Screw |

| PLC | Siemens | Siemens |

| Inverter | Schneider/ABB | Schneider/ABB |

【Product Installation Site Photos】

Whats App

Whats App

Plastmatch App

Scan the QR code

Plastmatch App

Scan the QR code 1000+ Daily Updated Global Business Leads,2M+ Global Company Database.Click to download the app.

Purchase request Download app