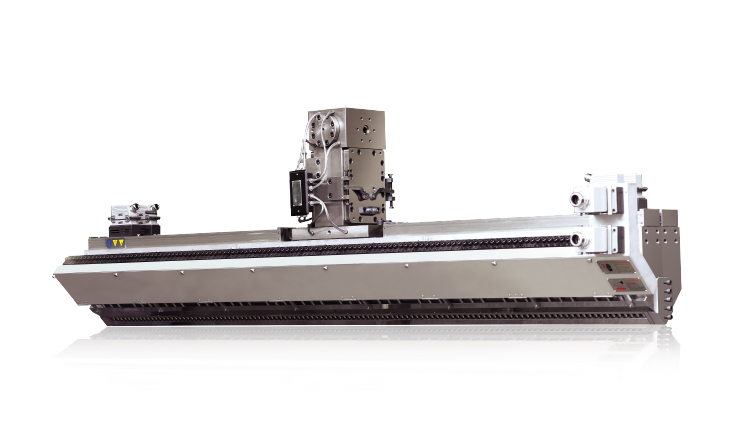

Based on years of experience in the plastic packaging industry and equipment usage, we excel in the manufacturing of rollers for plastic sheet, plate, and film equipment.

Roller Surface Treatment

● Tempering to ensure dense microstructure

● Deep quenching of the outer surface, achieving a hardness of HRC50~55

● Electroplating with hard chrome, achieving a hardness of HRC58~65

Surface Finishing Options

● Mirror and super-mirror grinding and polishing

● Custom processing of various textures such as leather grain, matte, frosted, sandblasted, and mesh patterns

● Surface coating with Teflon and various rubber-faced rollers

Roller Features

● Double-layer shell with internal helical flow channels for excellent heat dissipation

● Hot interference fit assembly ensuring high roller strength; crown compensation to reduce thickness errors in sheet and plate products

Based on years of experience in the plastic packaging industry and equipment usage, we excel in the manufacturing of rollers for plastic sheet, plate, and film equipment.

Roller Surface Treatment

● Tempering to ensure dense microstructure

● Deep quenching of the outer surface, achieving a hardness of HRC50~55

● Electroplating with hard chrome, achieving a hardness of HRC58~65

Surface Finishing Options

● Mirror and super-mirror grinding and polishing

● Custom processing of various textures such as leather grain, matte, frosted, sandblasted, and mesh patterns

● Surface coating with Teflon and various rubber-faced rollers

Roller Features

● Double-layer shell with internal helical flow channels for excellent heat dissipation

● Hot interference fit assembly ensuring high roller strength; crown compensation to reduce thickness errors in sheet and plate products

Modified Plastic Producers

Engineering Plastic Producers

Biodegradable Plastic Producers

Others

Others