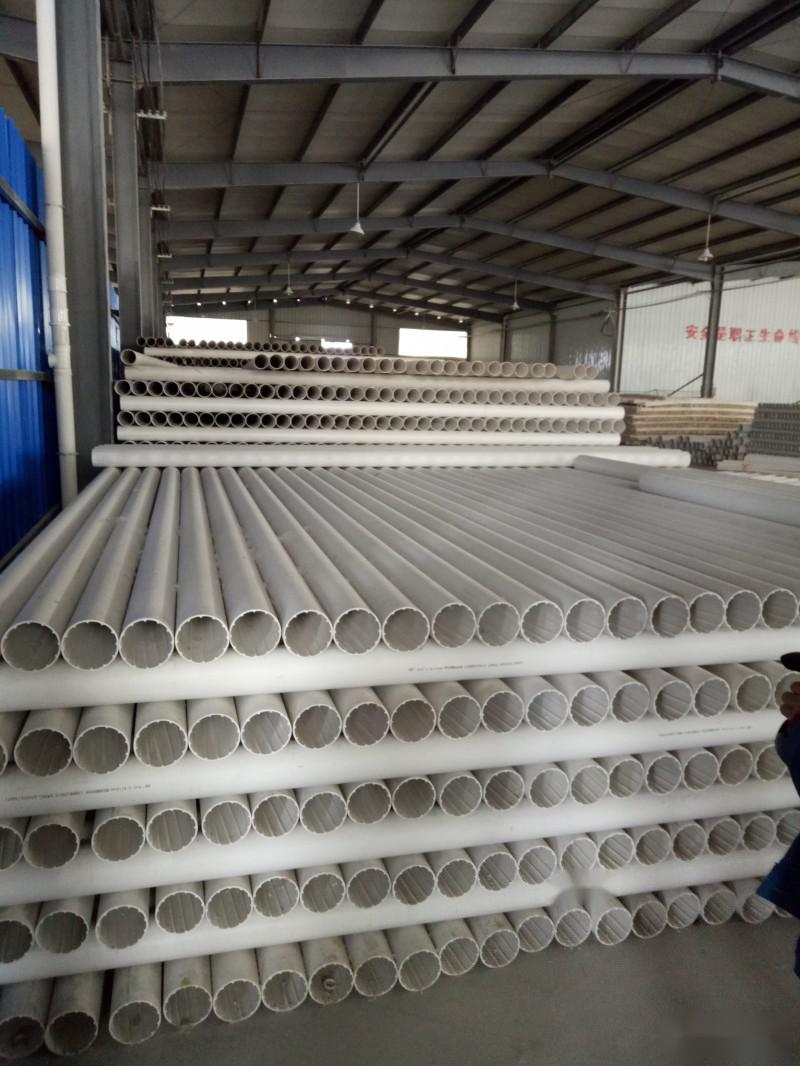

Applications of Pvc Soundproof Pipes

PVC-U soundproof pipes can be divided into: spiral soundproof pipes and double-wall spiral soundproof pipes

Features:

In addition to all the advantages of PVC-U solid wall pipes, it has a significant sound insulation effect, reducing noise by 8-10 decibels compared to standard solid wall pipes, effectively curbing the noise generated during wastewater discharge, making your living environment more cozy and quiet. This utility model relates to a spiral soundproof pipe, characterized by spiral ribs on the inner wall of the pipe, which are evenly distributed in a straight diagonal direction, forming an angle of 8°-20° with the centerline of the soundproof pipe. The feature of this utility model is that the inner wall of the pipe is equipped with straight diagonal spiral ribs, allowing the water to flow along the inner wall of the pipe in a straight line under the guidance of the spiral ribs during drainage, thus reducing strong impacts on the inner wall and resulting in lower noise.

Advantages:

1. Low cost: This product has a large drainage capacity, increasing drainage volume by 1/3 compared to standard specifications, significantly reducing material costs and saving on installation costs, resulting in a total cost reduction of over 30%, while also increasing usable indoor space.

2. Reduced water flow resistance: The water flow in the drainage vertical pipe exhibits noticeable wall-attached flow, which reduces water flow speed, decreases the water resistance coefficient, ensures smooth vertical flow, stabilizes pressure fluctuations within the pipe, enhances the drainage capacity of the vertical pipe, and lowers the gas volume by approximately 15-20%.2. Noise reduction: The spiral design of the pipe reduces collisions between the water flow, irregular air movement, and the pipe wall, standardizing the fluid direction, thereby lowering noise and achieving soundproofing effects.

3. Safety and hygiene: The spiral soundproof pipe and the double-wall spiral soundproof pipe have excellent pressure reduction performance, greatly improving the safety factor of drainage pipes in high-rise buildings.

4. Convenient installation and maintenance: Spirals soundproof pipes and double-wall spiral soundproof pipes below the 18th floor do not require the installation of vent pipes, H pipe accessories, etc. The horizontal and vertical pipes are removable, aesthetically pleasing, have good seismic resistance, and are easy and quick to install.

5. Increased pipe strength: The presence of an unobstructed air column inside the pipe reduces pressure fluctuations, enhancing the safety factor of the pipe's use. The six triangular spiral main ribs on the inner wall have a significant reinforcing effect, effectively reducing the risk of cracking caused by external impacts.

6. Reduced project costs: Using hollow wall spiral soundproof vertical pipes can eliminate the need for H type dual vertical pipe venting methods, thereby lowering project costs.

Precautions

1. Pipe processing: Once the length of the pipe is determined, it can be cut with a hand saw or circular saw blade. After cutting, both ends should be kept smooth, and burrs should be removed with a file, ensuring the angle is not too large.

2. Bonding pipe fittings: Before connecting, measure the length that the straight pipe should be inserted into the fitting socket, mark it on the straight pipe, install the cap and pressure ring first, then insert the vertical pipe into the fitting socket, apply adhesive, and tighten the cap to put it directly into use.

3. Pay attention to the direction of the rubber pressure ring during installation.

4. For vertical pipes within 3 meters of each layer, consider setting a clamp. A scientifically designed spiral soundproof pipe inner chamber should have a reasonable flow guide rib structure, which is designed based on scientific principles for the flow guide rib's rotation angle (e.g., right-hand spiral thread angle designed as α≤73°), height, width, and quantity of the flow guide ribs, aiming to achieve a good flow guidance effect. In vertical drainage system applications, the water flowing through the spiral soundproof pipe spirals along the flow guide ribs on the inner wall of the pipe, avoiding chaotic flow due to the guiding effect of the ribs, thus reducing the impact of the water flow on the pipe wall and lowering noise. Additionally, since the water flows spirally down along the inner wall of the pipe, an intermediate air passage is formed in the center of the drainage pipe, facilitating the smooth discharge of gases during vertical drainage and preventing noise caused by it. By enhancing the ventilation capacity of the vertical drainage system, air pressure resistance during water flow descent is eliminated, resulting in a stable and dense water flow along the inner wall of the drainage pipe, significantly improving water flow capacity. Good ventilation capacity also stabilizes pressure within the system, greatly enhancing the safety of the drainage system's use.