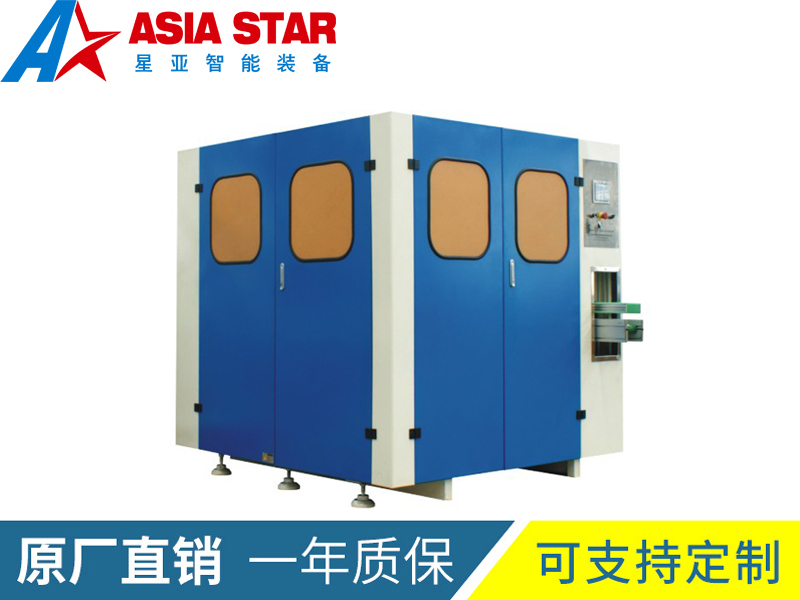

Product Description

PVC pipe production line, plastic pipe production line is mainly used for the production of various diameters and wall thicknesses of plastic PVC pipes for agricultural water supply and drainage, building water supply and drainage, cable laying, etc. The unit consists of a conical twin-screw extruder, vacuum sizing table, haul-off machine, cutting machine, and stacking rack. The screw extruder and haul-off machine adopt imported AC frequency conversion speed control devices, while the vacuum pump and haul-off motor use high-quality products. Haul-off options include two-claw, three-claw, four-claw, and six-claw traction methods. Saw blade or planetary cutting forms can be selected, and additional length measuring and thickening devices are available. The unit has reliable performance and high production efficiency. Our company can configure special equipment to produce spiral sound-absorbing pipes and core foam pipe units according to customer requirements.

This production line is mainly used for producing PVC pipes, which are widely applicable for building water supply pipes, sewage pipes, and drainage pipes.

The production line consists of a conical twin-screw extruder, vacuum calibrator, haul-off machine, cutter, material turning frame, and other components such as the screw extruder and haul-off machine.

The PVC pipe production line adopts imported AC variable frequency speed control devices. Both the vacuum pump and the traction motors use high-quality products. The traction methods include track type, two-claw, three-claw, four-claw, and six-claw.

(1) Raw material mixing for PVC plastic pipe extrusion production line: PVC stabilizers, plasticizers, antioxidants, and other additives are added to a high-speed mixer in a specific ratio and sequence according to the process. The materials are heated to the set processing temperature through self-friction with the machine. Then, the mixture is cooled down to 40-50°C using a cold mixer; after which it can be fed into the hopper of the extruder.

(2) Extruder section of the PVC plastic pipe extrusion production line: This machine is equipped with a metering feeding device to ensure that the extrusion rate matches the feed rate, guaranteeing stable product output. Due to the characteristics of the conical screw, the feed section has a larger diameter, providing a greater heat transfer area and shear rate, which is beneficial for the plasticization of the material. The metering section of the screw has a smaller diameter, reducing the heat transfer area and shear rate on the melt, allowing the melt to be extruded at a lower temperature. As the screw rotates inside the barrel, it plasticizes the PVC compound and pushes it towards the die head, achieving compaction, melting, homogenization, and also realizing degassing and dewatering. The feeding device and the screw drive mechanism use variable frequency speed control, enabling synchronous speed adjustment.

(3) Extrusion die section of the PVC plastic pipe extrusion line: The compacted, melted, and homogenized PVC, along with subsequent materials, is pushed towards the die by the screw. The extrusion die is a key component in the formation of the pipe.

(4) The vacuum sizing tank of the PVC plastic pipe extrusion line is a dual-cavity mold, used for shaping and cooling the pipes. The vacuum sizing tank is equipped with a vacuum system and water circulation system for shaping and cooling, featuring a stainless steel tank body and circulating water spray cooling. The vacuum sizing tank also has a front and rear moving device and manual adjustment devices for left-right and up-down positioning.

(5) The PVC plastic pipe extrusion line haul-off machine is used for continuously and automatically pulling out the cooled and hardened pipes from the die head, with variable frequency speed control.

(6) PVC plastic pipe extrusion line cutting machine: Controlled by a travel switch according to the required length, it performs automatic cutting and delays the flipping of the frame, enabling continuous production. The cutting machine follows the command from a fixed-length work switch signal to complete the entire cutting process. During cutting, it remains synchronized with the movement of the pipe. The cutting process is driven by electric and pneumatic systems. The cutting machine is equipped with a dust extraction device that promptly removes and recycles the debris generated during cutting.

(7) The flipping action of the material flipping frame on the PVC plastic pipe extrusion production line is achieved through pneumatic control by a cylinder. The material flipping frame is equipped with a limit device. After the cutting saw cuts the pipe, the pipe continues to be conveyed. After a delay, the cylinder starts working, performing the flipping action to achieve the unloading purpose. After unloading, it automatically resets after a few seconds of delay, ready for the next cycle.

Product Parameters

| Project | PVC63 | PVC160 | PVC250 | PVC315 | PVC450 | PVC630 |

| Production pipe specifications (mm) | φ16-φ63 | φ75-φ160 | φ125-φ250 | φ180-φ315 | φ200-φ450 | φ355-φ630 |

| Vacuum box length (mm) | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 |

| Vacuum (MPa) | -0.03~0.08 | -0.03~0.08 | -0.03~0.08 | -0.03~0.08 | -0.03~0.08 | -0.03~0.08 |

| Maximum Tractive Force (N) | 10000 | 15000 | 20000 | 25000 | 30000 | 50000 |

| Haul-off speed (m/min/max) | 10 | 6 | 4 | 3 | 2 | 1.4 |

| Effective draw length (mm) | 1000 | 1500 | 1500 | 1500 | 1800 | 1600 |

| Compressed air energy (m³/h) | 0.4 | 0.6 | 1.0 | 1.2 | 1.5 | 2.0 |

| Water consumption (m3/h) | 5 | 6 | 7 | 8 | 9 | 12 |

| Production line length (m) | 20 | 22 | 30 | 30 | 36 | 42 |

Industry Applications