PVC Free-Foam Board Mold\

Special hanger-type flow channel design, which can significantly reduce the scorching of heat-sensitive materials during the extrusion process. It features an adjustable upper lip, replaceable lower lip, and vertical throttle rod adjustment device, meeting the requirements for different thicknesses of products. Suitable for producing PVC free-foam boards with product thickness ranging from 2 to 20mm.

PVC Semi-Skin Foam Board Mold

The upper and lower lips are integrated with the main body and equipped with an embedded cooling die at the lip outlet, featuring seamless full-flow channel design. The upper lip adopts a specially designed push-type elastic fine-tuning structure for PVC foam board dies, ensuring sensitivity in adjustment due to reasonable screw spacing design. It also meets the requirement of locally adjustable lip outlet clearance, suitable for producing PVC semi-skin foam boards with product thickness ranging from 3 to 25mm.

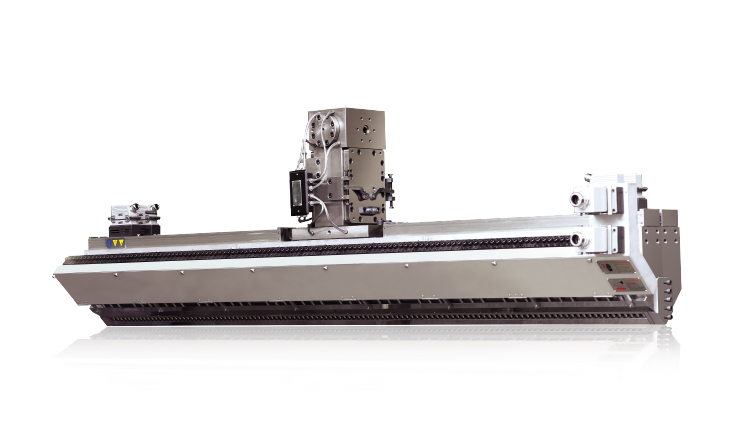

PVC Co-Extrusion Foam Board Mold

Special hanger-type flow channel design, which can significantly reduce the scorching of heat-sensitive materials during the extrusion process. It features the latest no-throttle rod and no-moving lip design, with a pull-type flexible fine-tuning die opening. This design meets the requirements for different thicknesses of products. The distributor uses the latest PVC dedicated co-extrusion distributor, suitable for producing PVC skin foam boards with product thickness ranging from 5 to 18mm.

PVC Dual-Flow Channel Foam Board Mold

Adopting a dual-flow channel design, adjustable upper and lower lips, and lip oil temperature control. The produced products have good surface skinning effect and low internal stress, truly achieving surface skinning foaming. Product thickness ranges from 12 to 35mm.

Modified Plastic Producers

Engineering Plastic Producers

Biodegradable Plastic Producers

Others

Others