● The production line adopts a Siemens human-machine interface and Siemens computer control operating system, enabling precise control and user-friendly operation of the equipment.

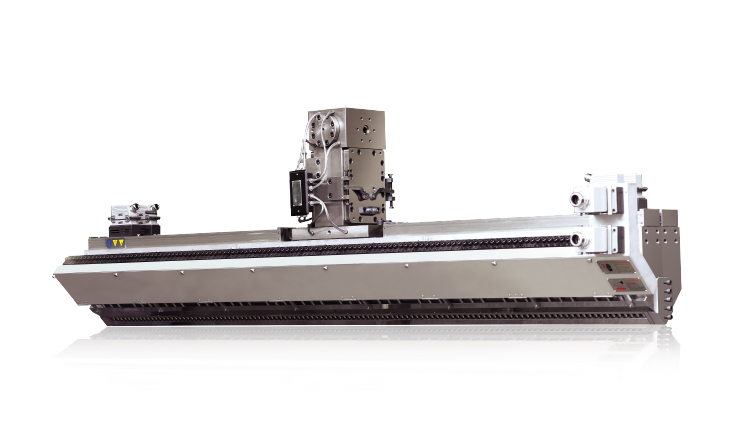

● The calendering machine uses super-mirror surface chrome-plated rollers and is equipped with servo motor drive, effectively ensuring product precision requirements.

● The specialized soft film rewinder ensures neat edges of finished rolls while preventing issues such as wrinkling, ribbing, and stretching.

PVC soft bags were developed to address the shortcomings of glass bottles, offering excellent chemical resistance and good temperature resistance. They are primarily used in applications like blood bags, urine bags, and drainage bags.

Non-PVC soft bags are a newer form of intravenous (IV) bag packaging that evolved after glass bottles, plastic bottles, and PVC soft bags. They are modified from PVC and retain its advantages while overcoming the toxicity issues associated with PVC materials. Additionally, they have significantly improved performance in reducing water vapor and gas permeability. Non-PVC IV soft bags use a closed infusion system with self-balancing pressure, eliminating the need for external air introduction and maintaining a sterile environment within the human circulatory system, thereby avoiding the risk of air pollution. This type of packaging is becoming increasingly popular for large-volume infusions. Non-PVC IV soft bags have excellent temperature resistance, so transportation is not restricted by seasons, and there's no need to worry about damage from severe shaking. Due to their anti-drop characteristics, they can be dropped from a certain height, making them suitable for disaster relief and emergency medical care.

| Model | JWS45/28-1500 | JWS90/28、JWS120/28-1500 |

|---|---|---|

| Material | PVC, EVA | PVC, EVA |

| Product Width | 400mm | 900mm |

| Product Thickness | 0.12-0.35mm | 0.12-0.35mm |

| Extruder Specification | JWS45/28 | JWS90/28 |

| Designed Extrusion Output | 20kg | 100kg-250kg |

Modified Plastic Producers

Engineering Plastic Producers

Biodegradable Plastic Producers

Others

Others