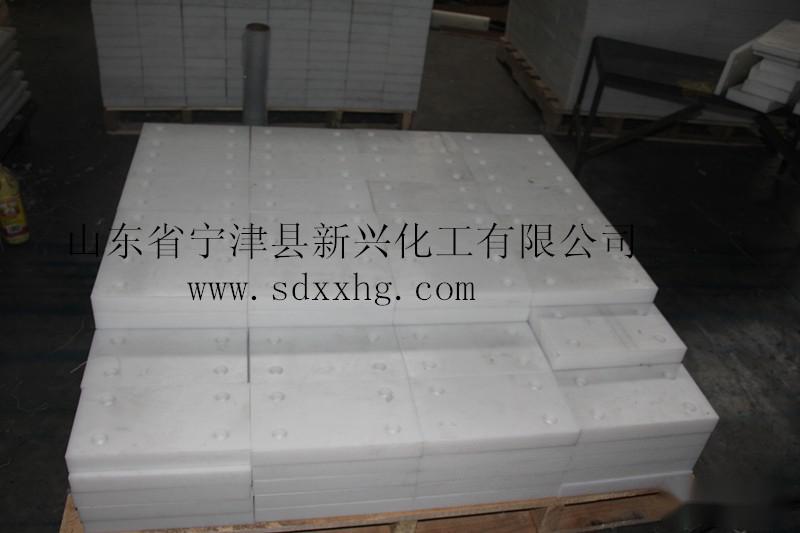

Protective Plate on Conveying Equipment - High Molecular Weight Polyethylene Plate, Wear-Resistant Polyethylene PlateProtective Plate on Conveying Equipment - High Molecular Weight Polyethylene Plate, Wear-Resistant Polyethylene Plate

Ningjin Xinxing Chemical Co., Ltd. in Shandong Province sincerely recommends high molecular weight polyethylene plates to you! It has successfully replaced steel plates, wooden boards, etc., with unique performance and advantages. It has a low coefficient of friction, is wear-resistant, self-lubricating, does not absorb water, does not adhere to materials, has high impact strength, good comprehensive mechanical properties, is resistant to acid, alkali, and salt corrosion, does not age, withstands low temperatures, is hygienic and non-toxic, and is lightweight, with a specific gravity of 1/8 that of steel – all the advantages of ultra-high molecular weight polyethylene plates! Ultra-high molecular weight polyethylene plates have replaced traditional wooden boards, steel plates, and iron plates, reducing equipment load, increasing output, directly lowering costs, enhancing economic benefits for enterprises, and winning user praise.

Now let’s detail the many characteristics of high molecular weight polyethylene plates:

Now let’s detail the many characteristics of high molecular weight polyethylene plates:

1. The wear resistance of ultra-high molecular weight polyethylene plates ranks first among plastics, and the higher the molecular weight, the greater the wear resistance and impact resistance of the material;

2. The impact strength of ultra-high molecular weight polyethylene plates is high among existing plastics, and it maintains a considerable impact strength even at 70°C;

3. Self-lubricating, low coefficient of friction, energy-saving, with a wax-like feel.

4. Extremely low water absorption. Therefore, its physical and mechanical properties are independent of the humidity factors in the working conditions used.

5. Ultra-high molecular weight polyethylene plates are chemically stable and can resist various corrosive media such as acids, alkalis, and salts, as well as organic solvents, within a certain temperature and concentration range.

6. Ultra-high molecular weight polyethylene plates are odorless, non-toxic, and non-corrosive, with physiological recyclability and adaptability.

7. Non-adhesive;

8. When the molecular weight of high-density polyethylene exceeds 500,000, the embrittlement temperature drops to 140°C. Ultra-high molecular weight polyethylene can even maintain certain mechanical strength at temperatures below -269°C under liquid nitrogen.

The high molecular weight polyethylene plates produced by Ningjin Xinxing Chemical Co., Ltd. are quality assured!

Practical Applications of High Molecular Weight Polyethylene Plates in Large Conveying Equipment:

Ultra-high molecular weight polyethylene possesses many excellent properties required for conveying equipment, making it significant for extending the service life of conveying equipment, reducing wear and impact, lowering equipment weight, and improving cost-effectiveness.

① In bucket elevators, ultra-high molecular weight polyethylene is used as the lining plate for the feed and discharge ports, and material deflectors, effectively reducing material wear on the machine cylinder and lowering the material breakage rate;

② In scraper conveyors, ultra-high molecular weight polyethylene is used for plastic scraper blades, idlers, wear-resistant guide rails, and wear-resistant linings of machine casings, fully utilizing the excellent wear resistance, impact resistance, hygiene, non-toxicity, self-lubrication, and non-adhesiveness of ultra-high molecular weight polyethylene to improve the overall performance of the equipment. For example, COFCO Malt Jiangyin Co., Ltd. and Guangzhou Malt Co., Ltd. fully considered the moisture and adhesion characteristics of materials when designing and manufacturing scraper conveyors, using ultra-high molecular weight polyethylene plates as the casing lining throughout the entire scraper conveyor line, improving the equipment’s quality and lifespan.

③ In belt conveying equipment, buffer strips at the feed inlet (composed of ultra-high molecular weight polyethylene plates, buffer rubber, and metal components) and scraper plates on the belt can reduce belt wear and absorb impact from falling materials. This component has been promoted in belt conveyors in industries such as mining and metallurgy.

④ The lining of silos, chutes, and slides can reduce wear of the materials against the walls of the silo and pipes, facilitate maintenance and replacement, extend the lifespan of facilities and equipment, and reduce maintenance costs. For example, in flour mills conveying wheat, flour, and grains, steel pipes wear through in just four months, while flour mills in Beijing, Qingdao, and other places use ultra-high molecular weight polyethylene sheets rolled into pipes as steel pipe linings, improving wear resistance by 7 to 10 times, reducing noise, and improving the environment.

Protective Plate on Conveying Equipment - High Molecular Weight Polyethylene Plate, Wear-Resistant Polyethylene PlateProtective Plate on Conveying Equipment - High Molecular Weight Polyethylene Plate, Wear-Resistant Polyethylene Plate

Ningjin Xinxing Chemical Co., Ltd. in Shandong Province specializes in producing wear-resistant liners for belt conveyors and conveying machines, wear-resistant apron boards, high molecular weight polyethylene base plates, and polyethylene side plates, also known as ultra-high molecular weight polyethylene plates. These can replace traditional steel plates with excellent characteristics such as lightweight, good wear resistance, and easy installation, effectively protecting machinery and increasing service life! Custom specifications for liners and protective plates can be processed according to machine dimensions!

Mobile: 13173333540

Landline: 0534-5223277

Online QQ: 2875013107

Email: xxhgzlz@163.com

Company Website: www.sdxxhg.com

Shandong Xinxing Chemical Zhang Long is dedicated to serving you!