Product Details:

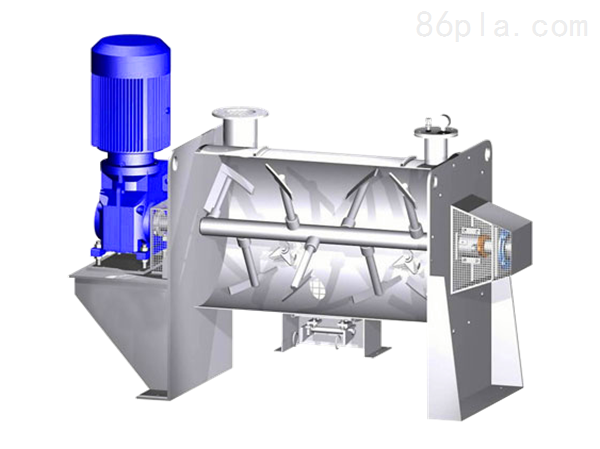

Brief Description: When the internal mixer for plastic compounding is in operation, the two rotors rotate relative to each other, gripping the material fed from the hopper and carrying it into the gap between the rolls where it undergoes compression and shearing by the rotors. After passing through the gap, the material hits the sharp edge of the lower plunger and is divided into two parts, which then return to the top of the gap via the spaces between the front and rear chamber walls and the rotors.

Features of the Internal Mixer for Plastic Compounding:

1. The temperature control during the mixing process is extremely precise. All components that come into contact with the material are cooled by water, and the flow rate and volume are precisely controlled by a temperature control system, ensuring temperature variations within ±3°C.

2. The leakage prevention effect during the mixing process is the best domestically, being 2-3 times more effective than domestic models. It uses an alloy ring and sealing ring combination for automatic compensation and manual adjustment, completely preventing powder leakage. The Taiwanese GaoShan sealing ring has a semi-circular structure for easy replacement.

3. The mixing chamber and mixing shaft are made from alloy wear-resistant materials and undergo multiple processing steps, making them resistant to wear and breakage.

4. The gearbox is produced by a domestic gearbox manufacturing company, specifically designed for internal mixers with hard tooth surfaces, providing low vibration, low noise, and smooth transmission.

5. The electrical control system is designed ergonomically with increased electrical capacity for ease of operation and various maintenance systems.

Maintenance and Care of the Internal Mixer for Plastic Compounding:

1. Before starting, check for any foreign objects between the rotors in the mixing chamber, as well as the integrity of the upper and lower plungers, flap doors, instruments, and signal devices before preparing to start.

2. Issue a signal before starting and confirm there is no danger before proceeding.

3. Before feeding material, close the lower plunger first and add materials one by one. Powder should be handled gently, and carbon black bags should be fed mouth-down into the air duct one at a time.

4. Do not look into the mixing chamber while it is running. If necessary, use a hook to secure the feed port flap door and lift the upper plunger with a safety pin before looking inside.

5. Stop the machine immediately if any foreign objects fall into the mixing chamber or if any faults occur.

6. In case of sudden shutdown, lift the upper plunger and insert the safety pin, open the lower plunger, cut off power, and close water and steam valves. If manually rotating the coupling to discharge material, ensure proper coordination and never start with material inside.

7. If the upper plunger gets stuck by the material, stop the machine for handling. Do not remove leaked material from the lower plunger by hand; use an iron hook instead.

8. Stand outside the active area of the feed port flap when operating, and do not stand below the discharge port.

9. Use signals to communicate with the next process step for discharging material, changing varieties, or stopping.

10. After stopping, insert the safety pin, close the flap door, lower the upper plunger, open the lower plunger, close the air, water, and steam valves, and cut off power.