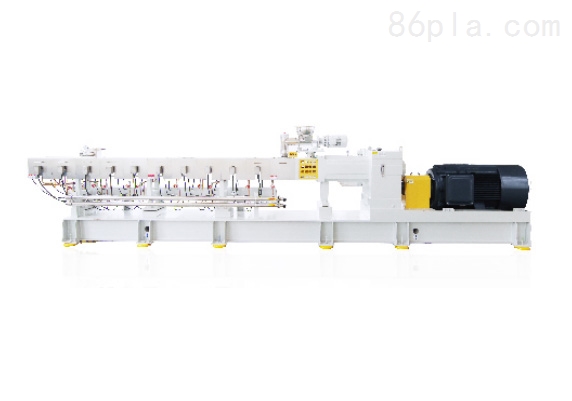

Extrusion-type Fully Automatic Pelletizing Machine Working Process:

1、The entire process consists of two procedures: mixing and granulation.

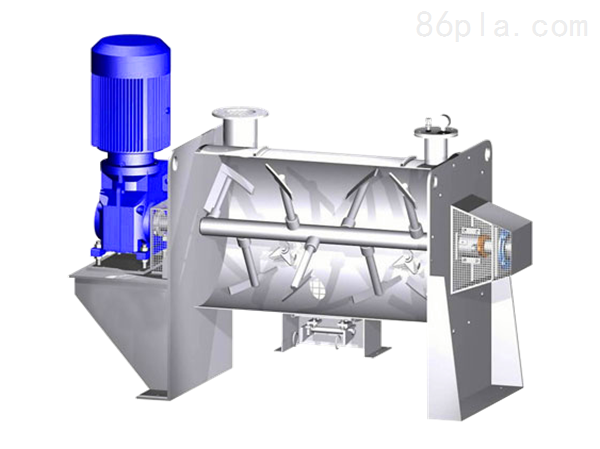

2、The binder enters the material pot from a conical hopper. After closing the hopper, the powder material rotates under the stirring of the mixing blades. Meanwhile, the material changes direction along the conical wall, gradually forming liquid bridges. Under the squeezing, friction, and kneading effects of the blades and cylinder walls, the material gradually transforms into loose material. Then, by opening the discharge door, the mixed particles are pushed out of the hopper due to the centrifugal force of the blades.

3、The soft material with a lumpy structure is not formed by forced extrusion but by cutting through the granulating force. The soft material in a semi-fluid state is cut into fine and uniform particles, achieving mutual transformation of the material.

Precautions:

1、Before starting, heat for about 40 to 50 minutes to raise the temperature to a level that makes it easier to manually pull the motor's V-belt. Pull 8 to 10 times in the normal working direction, then continue heating for another 10 minutes while maintaining the heat as continuous production requires constant heat supplementation. Adjust the temperature according to the different properties of the plastics.

2、Before normal operation, maintain stable mechanical temperature and avoid keeping the temperature too high or too low.

3、If feeding is uniform, the machine's feed rate should match the conveying speed; otherwise, it will directly affect the quality and output of plastic pellets.

4、Before stopping, all plastic inside the pelletizer's screw must be cleared and cleaned.

5、When shutting down the main unit, disconnect the power supply. Before the next use, disassemble and preheat the magnetic head plug separately.

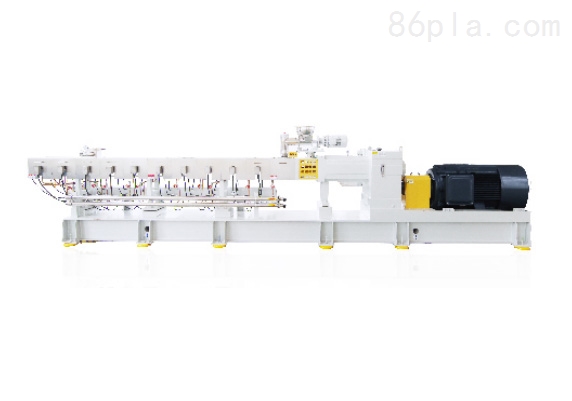

Maintenance of the Extrusion-type Fully Automatic Pelletizing Machine:

1、Place the equipment in a well-ventilated position to ensure heat dissipation from the motor, extending its lifespan.

2、Regularly lubricate the bearings to ensure proper lubrication.

3、Periodically check the blade screws. After using for one hour, tighten the screws of the moving and fixed blades with tools to enhance the fixation between the blade and the frame.

4、To ensure the sharpness of the blades, regularly inspect them to maintain their sharpness, reducing unnecessary damage to other components caused by dull blades.

5、When replacing the blades, adjust the gap between the moving and fixed blades: for 20HP or higher, if recycling thinner material, the gap can be appropriately increased.

6、Before the second start-up, clear any remaining fragments in the machine room to reduce startup resistance.

7、Regularly open the inertia cover and pulley cover to clean the dust outlet below the flange because powder material from the pelletizing machine may enter the rotating shaft bearings.

8、Ensure good grounding for the old inventory resin pelletizing machine.

We hope the above content helps you better understand this equipment.