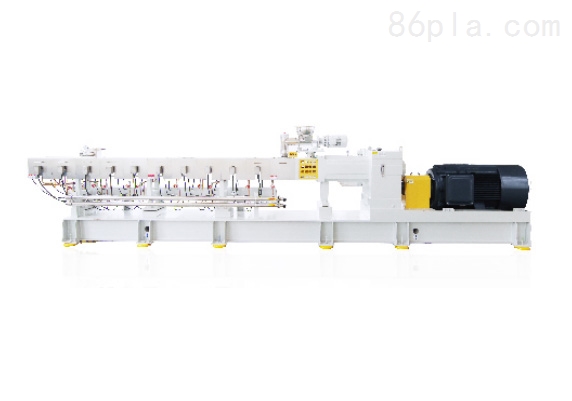

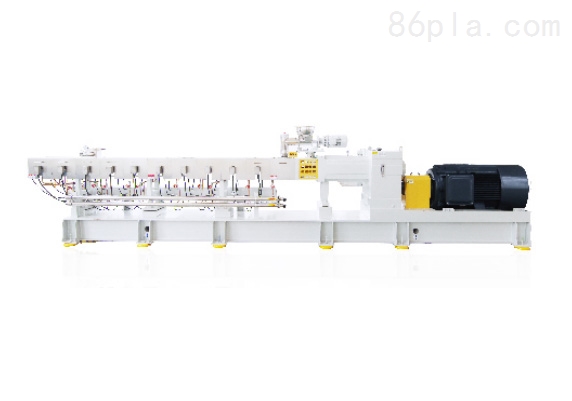

Introduction to the Color Masterbatch Pelletizing Machine:

This machine is primarily used for coloring polymer materials, mainly divided into black masterbatch, white masterbatch, colored masterbatch, and liquid masterbatch.

Features:

1. This production line integrates mixing, conveying, feeding, and extrusion pelletizing, achieving automated continuous operation with high production efficiency.

2. Compact structure, small footprint and space, suitable for flat installation.

3. The production process involves segmented closed-loop temperature control, with independent heating and cooling systems for kneading, feeding, and extruding, controlled according to process requirements.

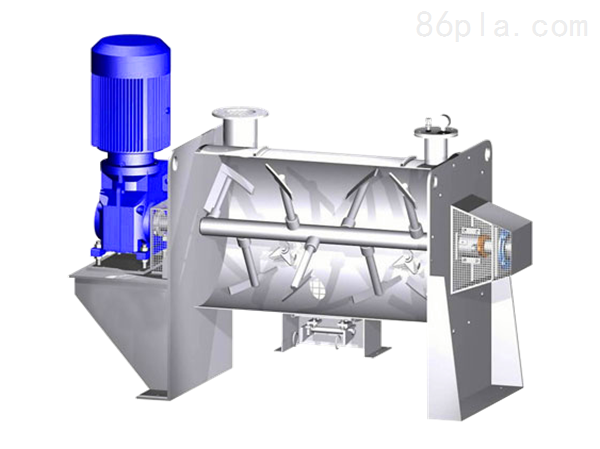

4. The feeding mechanism uses a twin-screw paddle design, providing strong feeding capability. It is particularly suitable for extrusion granulation of lump materials directly from the kneader.

5. The barrel and screw are made of high-quality alloy steel 38CrMoAIA, nitrided for high hardness, wear resistance, and corrosion resistance.

6. The die head features manual screen changing or quick non-stop screen changing mechanisms to improve production efficiency.

7. The electrical control system uses advanced PLC technology with multiple frequency converters, enabling precise and wide-ranging speed adjustments for feeding, extruding, and cutting according to process requirements. It also includes interlocks for the entire process and audio-visual fault alarms, ensuring reliable operation.

Precautions for the Color Masterbatch Pelletizing Machine:

1. Before starting, heat for about 40 to 50 minutes to raise the temperature to a level where it can be easily adjusted by hand. Pull the motor V-belt in the normal working direction 8 to 10 times, then continue heating for another 10 minutes. Continuous heating is necessary as normal production requires continuous heat supply. Adjust the temperature according to the properties of different plastics.

2. Before normal operation, maintain stable mechanical temperature without keeping it too high or too low.

3. If feeding is uniform, the machine's feeding speed should match the delivery speed; otherwise, it will directly affect the quality and output of plastic pellets.

4. Before stopping, all plastic inside the pelletizer screws must be cleared and cleaned.

5. When shutting down the main unit, disconnect the power supply. Before the next use, disassemble and preheat the magnetic head plug separately.