PP honeycomb board is a three-layer sandwich panel formed in one extrusion process. The two outer layers are relatively thin, while the middle layer has a honeycomb structure. Depending on the honeycomb structure, it can be divided into single-layer and double-layer boards. PP honeycomb board can also be produced with fabric or leather covering on both sides in one process, offering advantages such as lightweight and high rigidity, non-toxic and environmentally friendly, shock absorption, cold resistance, sound insulation, thermal insulation, moisture-proofing, and heat insulation.

1. It is used for interior parts of passenger vehicles, including trunk lid panels, trunk partition boards, trunk carpet baseboards, side trim panels, ceilings, etc.;

2. It is used to make various high-strength packaging boxes.

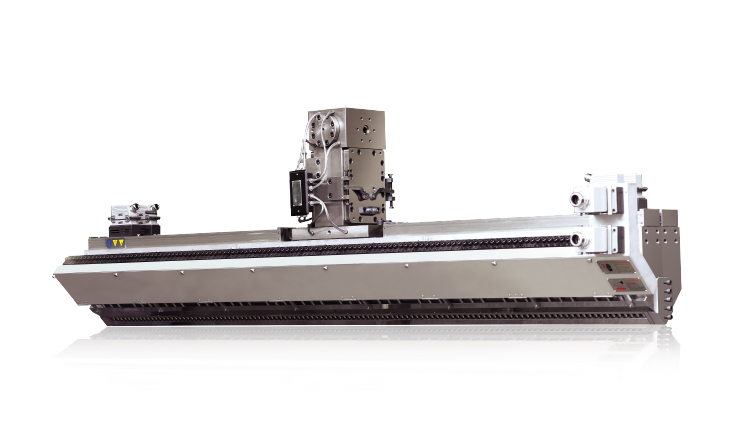

Main Technical Parameters

| Model | Suitable Material | Product Width (mm) | Product Thickness (mm) | Capacity (kg/h) |

|---|---|---|---|---|

| JWS75/75/75 | PP | 1200-1600 | 2-12 | 350-450 |

| JWS100/100/100 | PP | 1200-2000 | 2-20 | 600-700 |

| Note: The information listed above is for reference only. The production line can be customized according to customer requirements. | ||||

Modified Plastic Producers

Engineering Plastic Producers

Biodegradable Plastic Producers

Others

Others